Multipurpose heat exchange reaction device

A reaction device and a multi-purpose technology, applied in the field of multi-purpose heat exchange reaction devices, achieves the effects of uniform heat transfer, simple and convenient maintenance, and simplified control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

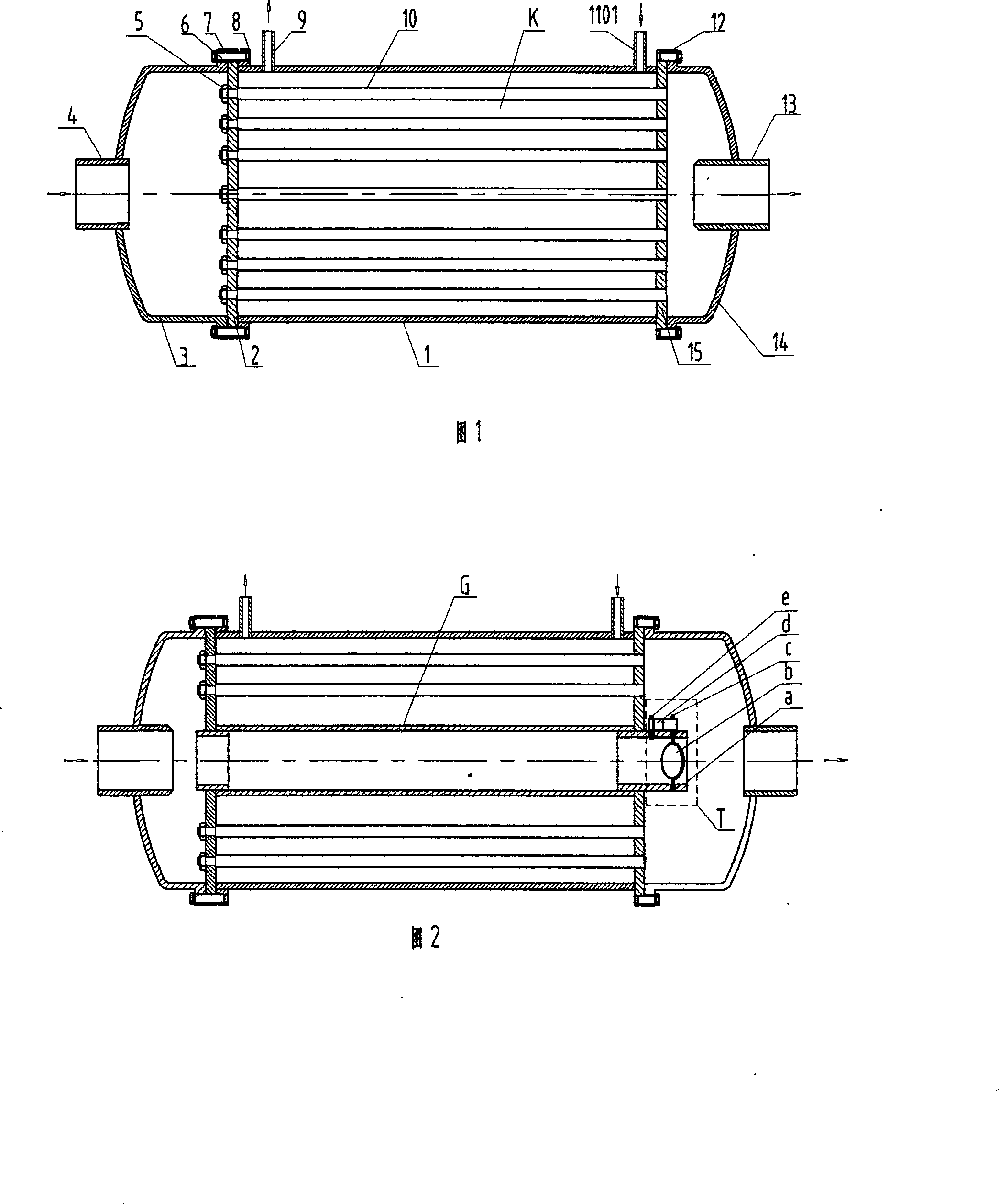

[0018] As shown in FIG. 1 , it includes a heat exchange reaction device consisting of a cylinder body 1 , a heat source fluid discharge end cover 14 , a heat source fluid inlet end cover 3 , several heat exchange tubes 10 , a bottom tube sheet 15 and an open tube sheet 2 . One end of the cylinder 1 is welded with a bottom tube plate 15, and the other open end has a cylinder flange 8, and the outer walls of the two ends of the cylinder 1 are respectively provided with a material inlet pipe 1101 and a material discharge pipe 9; the heat source fluid enters the open end of the end cover 3 There is a left end cover flange 7, and there is a heat source fluid inlet pipe 4 at the top; an open tube plate 2 is crimped between the left end cover flange 7 and the cylinder flange 8 through a screw 6; the heat source fluid discharge end cover 14 has a right end at the open end The cover flange 12 has a heat source fluid discharge pipe 13 on the top; the right end cover flange 12 is engaged ...

Embodiment 2

[0020] As shown in Figure 2, it consists of a cylinder body 1, a heat source fluid discharge end cover 14, a heat source fluid inlet end cover 3, a number of heat exchange tubes 10, a temperature-adjusting heat exchange tube G, a thermostat T, a bottom tube plate 15 and an opening A heat exchange reaction device composed of tube sheets 2. One end of the cylinder 1 is welded with a bottom tube plate 15, and the other open end has a cylinder flange 8, and the outer walls of the two ends of the cylinder 1 are respectively provided with a material inlet pipe 1101 and a material discharge pipe 9; the heat source fluid enters the open end of the end cover 3 There is a left end cover flange 7, and there is a heat source fluid inlet pipe 4 at the top; an open tube plate 2 is crimped between the left end cover flange 7 and the cylinder flange 8 through a screw 6; the heat source fluid discharge end cover 14 has a right end at the open end The cover flange 12 has a heat source fluid dis...

Embodiment 3

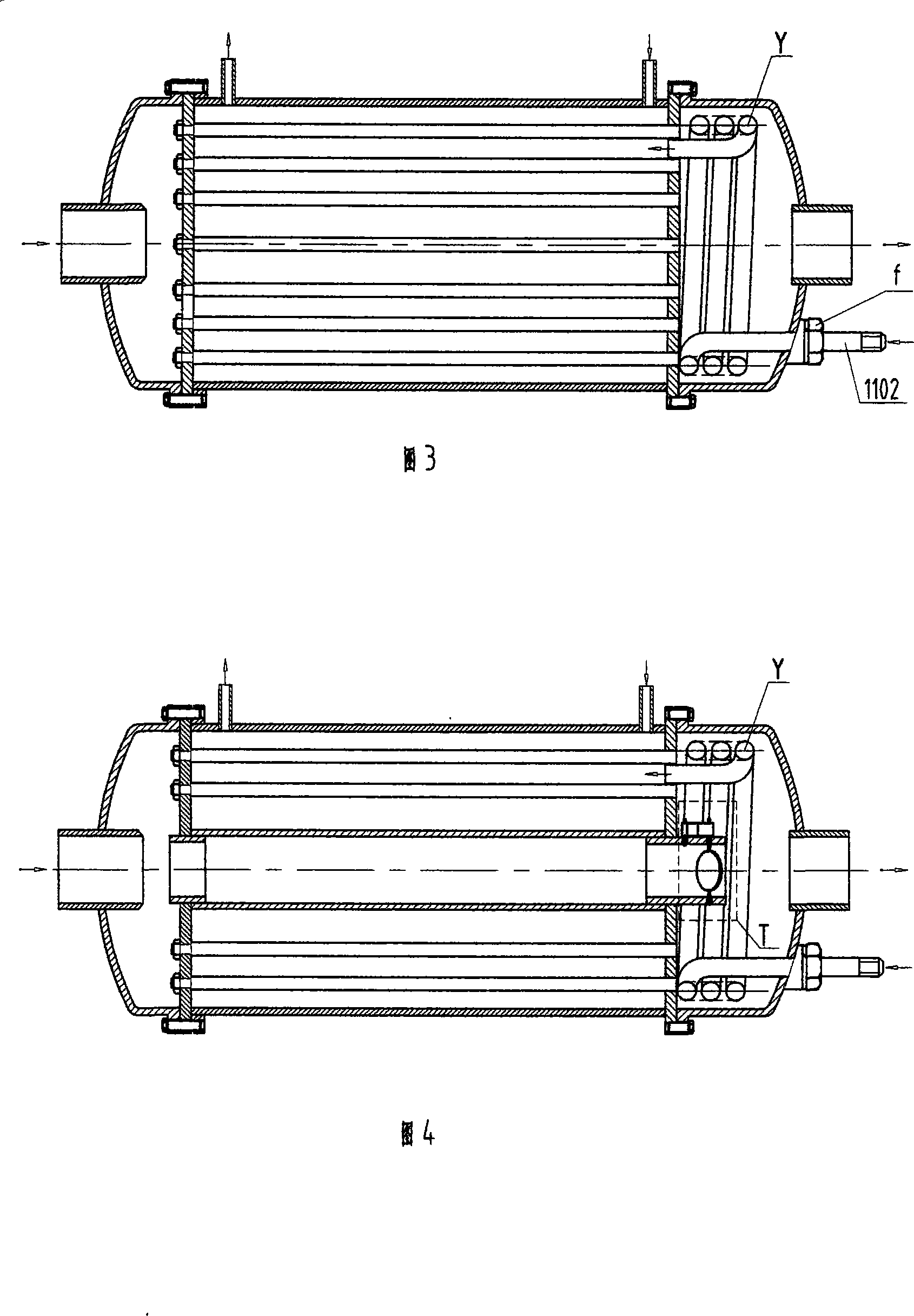

[0023] As shown in Figure 3, it includes a heat exchange system composed of a cylinder body 1, a heat source fluid discharge end cover 14, a heat source fluid inlet end cover 3, several heat exchange tubes 10, a preheater Y, a bottom tube plate 15 and an open tube plate 2. Reactor. One end of the cylinder 1 is welded with a bottom tube plate 15, and the other open end has a cylinder flange 8, and the outer walls of the two ends of the cylinder 1 are respectively provided with a material inlet pipe 1101 and a material discharge pipe 9; the heat source fluid enters the open end of the end cover 3 There is a left end cover flange 7, and there is a heat source fluid inlet pipe 4 at the top; an open tube plate 2 is crimped between the left end cover flange 7 and the cylinder flange 8 through a screw 6; the heat source fluid discharge end cover 14 has a right end at the open end The cover flange 12 has a heat source fluid discharge pipe 13 on the top; the right end cover flange 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com