Pressure structure clamp and fiber compound material combination expander technology

A fiber-reinforced and composite material technology, applied in the direction of manufacturing tools, workpiece clamping devices, pipe components, etc., can solve problems such as difficult to achieve reinforcement effects, and achieve the effects of extensive crack arrest, internal pressure resistance, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Example 1 Pipeline Mechanical Damage Defect Reinforcement Experiment

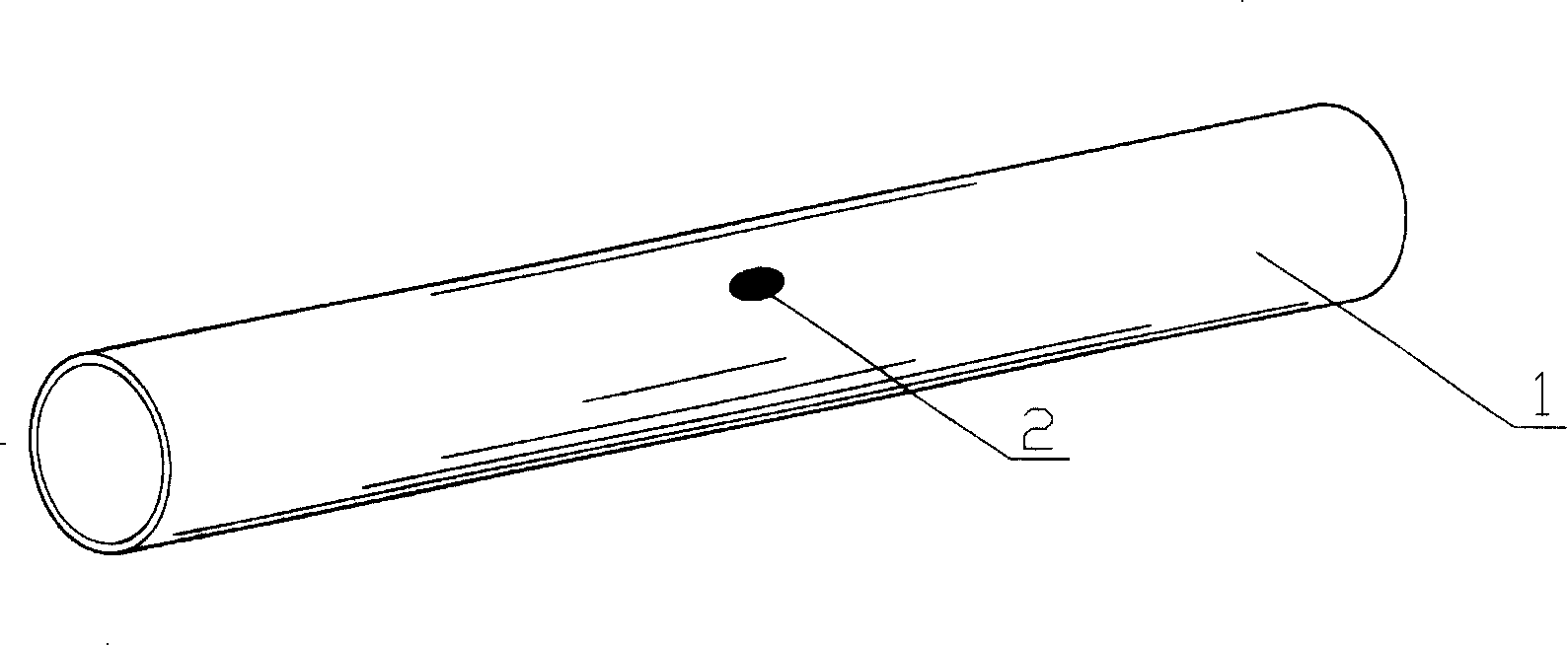

[0110] The diameter of the pipe chosen for the experiment is Φ720mm, the wall thickness is 9mm, and the material is Q235b. There is a mechanical damage 40mm long, 10mm wide, and 4.5mm deep on the pipe. Such as figure 1 . The pipeline is repaired and reinforced by using the technology of injecting curable polymer into the composite material reinforced clamp of the present invention.

[0111] The experiment is carried out as follows:

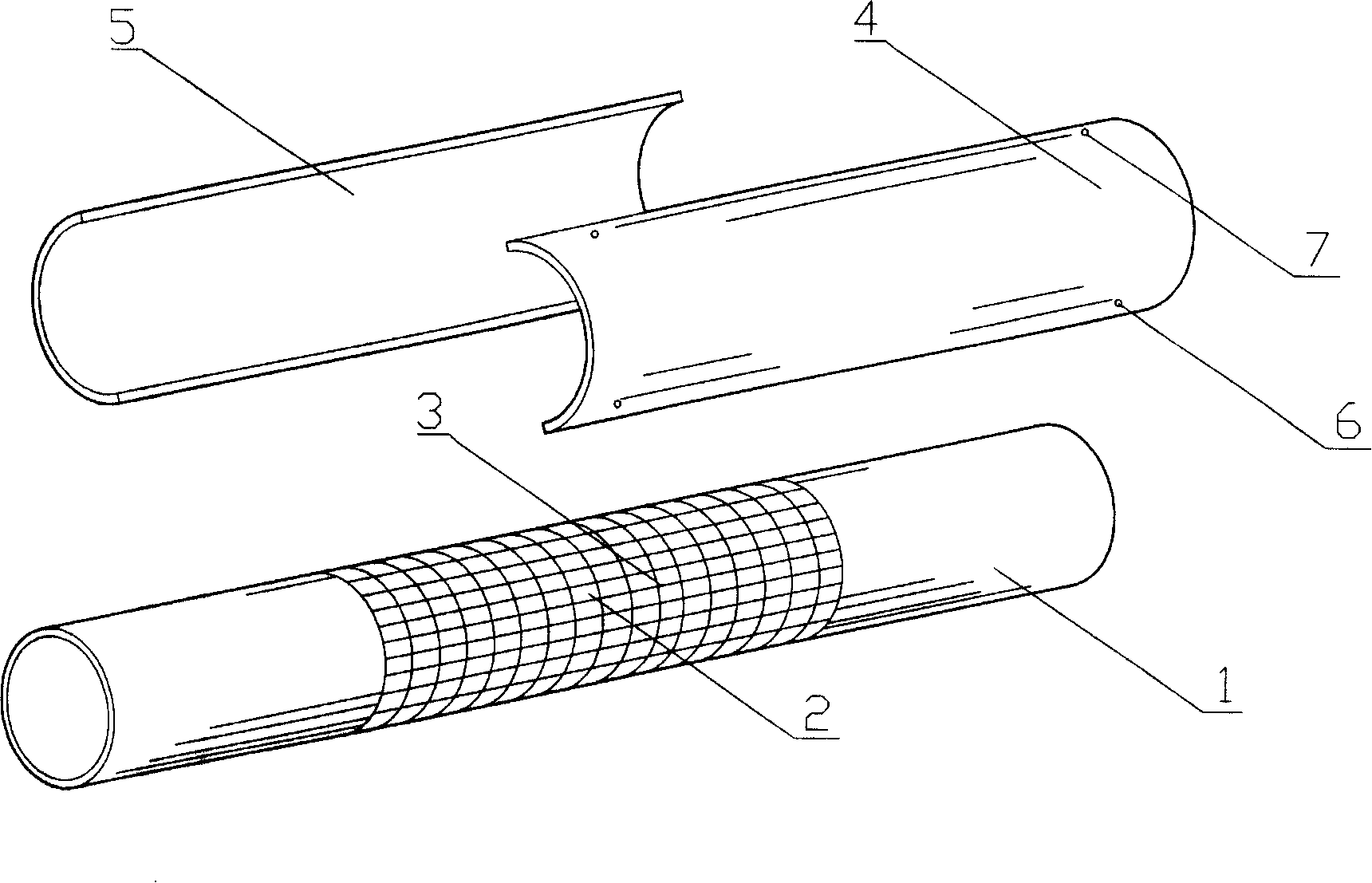

[0112] 1. Carbon fiber composite reinforcement

[0113] Firstly, the surface of the metal pipe (1) is cleaned;

[0114] Repair the defects on the surface of the metal pipe: fill the mechanical damage defect (2) on the surface of the steel pipe with filling resin, and repair it until the surface is smooth;

[0115] Wet bonding of carbon fiber cloth: 200mm in length and 2170mm in width, 1 layer of carbon fiber is pasted along the axial direction of the pipeline, wher...

Embodiment 2

[0129] Example 2 Reinforcement experiment of cross pipe support

[0130] The pipe (1) selected for the experiment has a diameter of Φ720mm, a wall thickness of 9mm, and a material of Q235b. There is a 600mm long cross fixed pipe support (welded axial thrust pipe support) directly below the pipe. The engineering design pressure of the pipeline is 4.3MPa, and the pipeline is reinforced by injecting curable polymer technology into the composite material reinforcement fixture of the present invention to increase the pressure.

[0131] The experiment is carried out as follows:

[0132] 1. Carbon fiber composite reinforcement

[0133] Firstly, surface cleaning of metal pipes;

[0134] Repair the defects on the surface of the metal pipe: fill the concave parts on the surface of the steel pipe, such as honeycomb, pockmarked surface, small hole, near the weld, etc., with repair glue, and repair until the surface is smooth;

[0135] Wet paste carbon fiber cloth: according to length ...

Embodiment 3

[0149] Embodiment 3 Girth weld reinforcement experiment

[0150] The diameter of the pipe chosen for the experiment is Φ325mm, the wall thickness is 7mm, and the material is Q235b. The middle of the pipe is a girth weld, and the length of the fixture is 400mm (see attached Figure 9 ).

[0151] The experiment is carried out as follows:

[0152] 1. Carbon fiber composite reinforcement

[0153] Firstly, surface cleaning of metal pipes;

[0154] Fill in the vicinity of the weld with repair glue to repair until the surface is smooth;

[0155] Wet paste carbon fiber cloth (see attached Figure 10 ).

[0156] The carbon fiber composite material is solidified to reach strength, and the next step is performed.

[0157] 2. Making jigs

[0158] Similar to Example 1, according to pipeline structure and shape, processing fixture (see attached Figure 9 ).

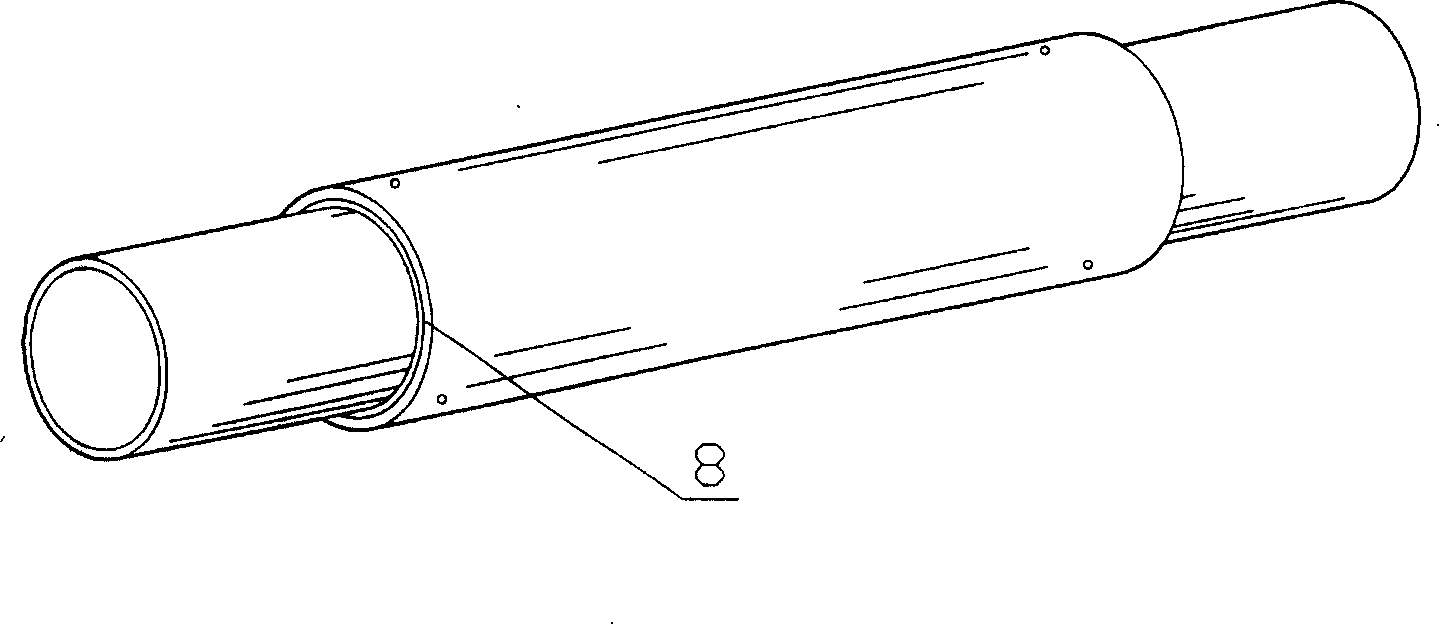

[0159] 3. Assembly and installation of fixtures (see embodiment 1)

[0160] 4. Sealing of annular space.

[0161] Use sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com