Double sealing high pressure needle valve

A high-pressure needle and double-sealing technology, which is applied in the direction of lift valves, valve devices, engine components, etc., to achieve the effects of long service life, good sealing performance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

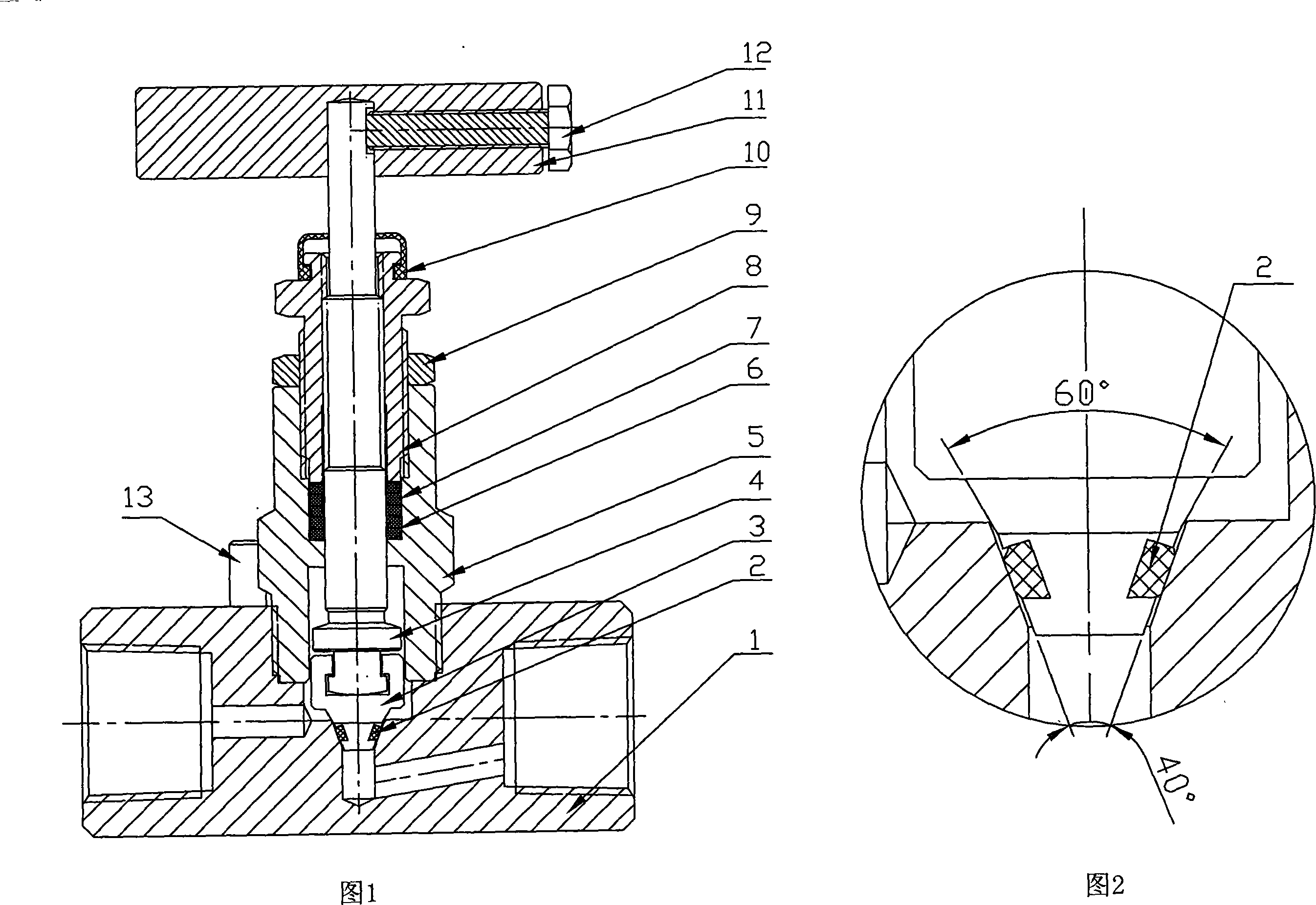

[0011] As shown in the accompanying drawings, the double-sealed high-pressure sealing needle valve of the present invention mainly includes a valve body 1, a valve tip 3, a valve stem 4, an upper valve cover 5, and a handle 11. The valve tip 3 and the valve stem 4 are formed by a T-shaped groove No swing hitch. The valve tip seal includes a hard seal part and a soft seal part. The taper of the hard seal part is larger than the taper of the soft seal part, and the taper of the hard seal part is consistent with the taper of the upper part of the valve body sealing port, generally 60°±1°, which forms a sealing line in sealing contact with the upper line of the valve body sealing port; the soft seal The taper surface of the upper part is consistent with the cone surface of the lower part of the valve body sealing port, generally 40°±1°, machined into a trapezoidal groove and assembled with a fluororubber O-ring 2, the fluororubber O-ring 2 is higher than the valve tip 3 The cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com