On-line equipment auxiliary managerial method and system using said method

A technology of equipment and equipment groups, applied in general control systems, control/regulation systems, nonlinear optics, etc., can solve problems such as inability to calculate the utilization rate of equipment groups, and achieve the effect of avoiding manual calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

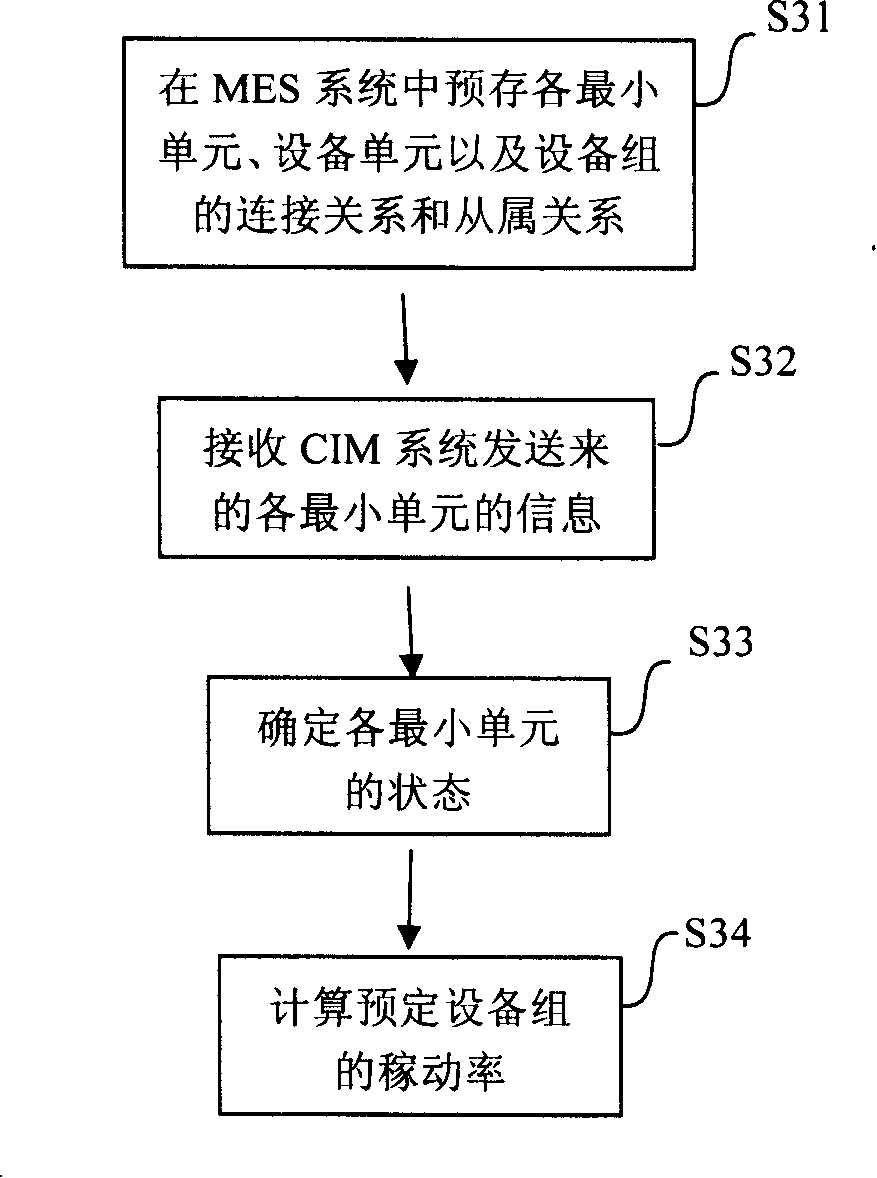

[0139] This embodiment is used for the production in the liquid crystal dropping process, and is used to calculate the utilization rate of the equipment group consisting of the cushion spreading inspection device, the first spreading device, the second spreading device and the cushion fixing device, as shown in Fig. 15 with oblique line device.

[0140] For the connection relationship between the dunnage spreading inspection device, the first spreading device, the second spreading device and the dunnage fixing device, see Figure 16 . The dunnage spreading inspection device, the first spreading device, the second spreading device and the dunnage fixing device are respectively defined as four smallest units U3, U17, U18 and U4, and the combination G of U17, U18 and U3 1 Defined as a device unit, the G composed of U4 2 Defined as a device unit, the G 1 and G 2 device group G 0 Defined as device groups.

[0141] The first spreading device and the second spreading device are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com