A method for acquiring automatic processing data of hull curved plate welding variable groove

A technology of automatic processing and acquisition methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of cumbersome calculation process, error-prone, and low efficiency, and achieve simple operation, high efficiency, and easy popularization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

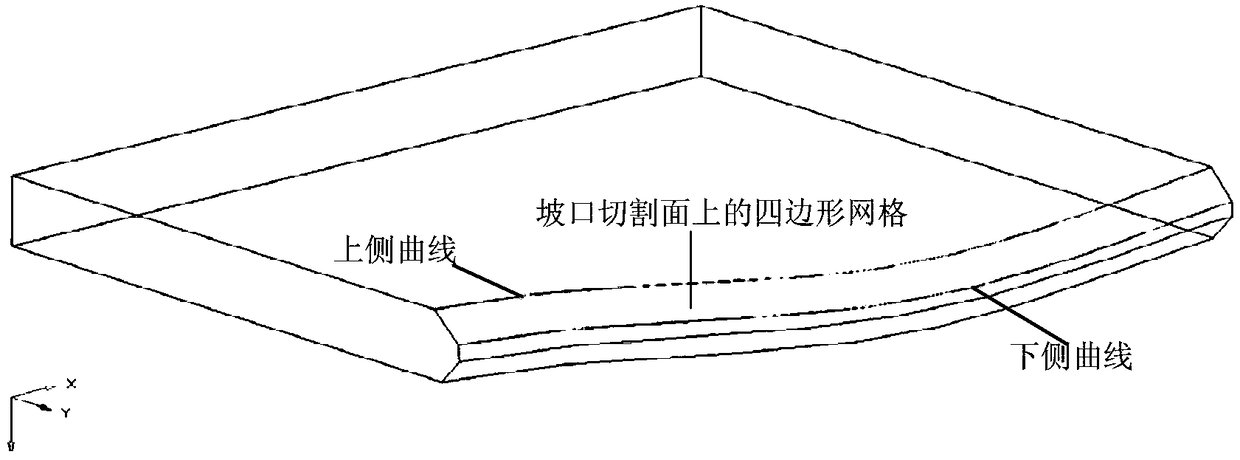

[0032] The technical solution adopted by the present invention is to integrate three-dimensional CAD cutting, chamfering algorithm and Hypermesh grid division algorithm, convert the variable groove surface data into variable groove finite element grid node data, further program and read the node data, and finally obtain the automatic Process the coordinate data of the three-dimensional space movement of the plasma gun, and finally realize the automatic processing of the variable groove. The specific process is as follows:

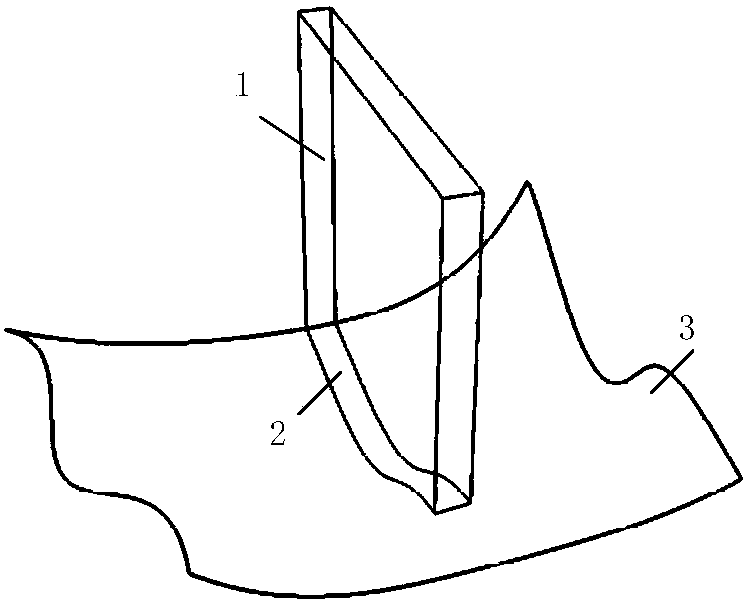

[0033] 1. Obtain the model information of the joint surface of the rib plate and the curved outer plate. Import the 3D model of the rib plate and the outer plate designed by the shipyard into the 3D system, and extract the joint surfaces of the two (such as figure 1 shown). This process can be realized by the 3D design software Catia.

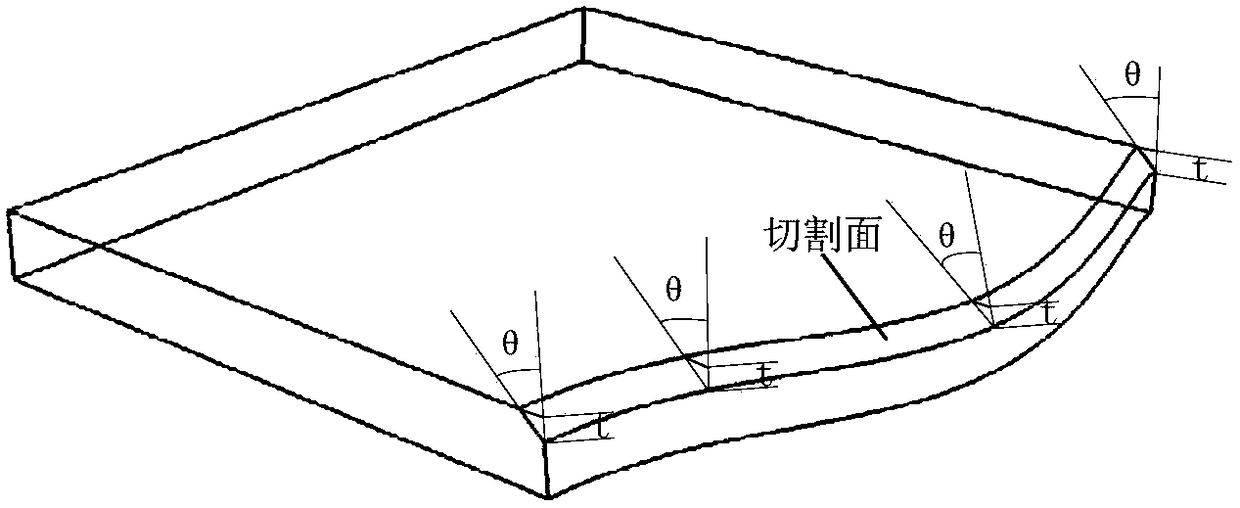

[0034] 2. Obtain the variable bevel cutting surface. Input the groove angle θ and the groove edge distance t, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com