Fuel vapor systems for internal combustion engines

A technology of fuel vapor, internal combustion engine, applied in the field of systems, capable of solving problems for which solutions have not yet been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

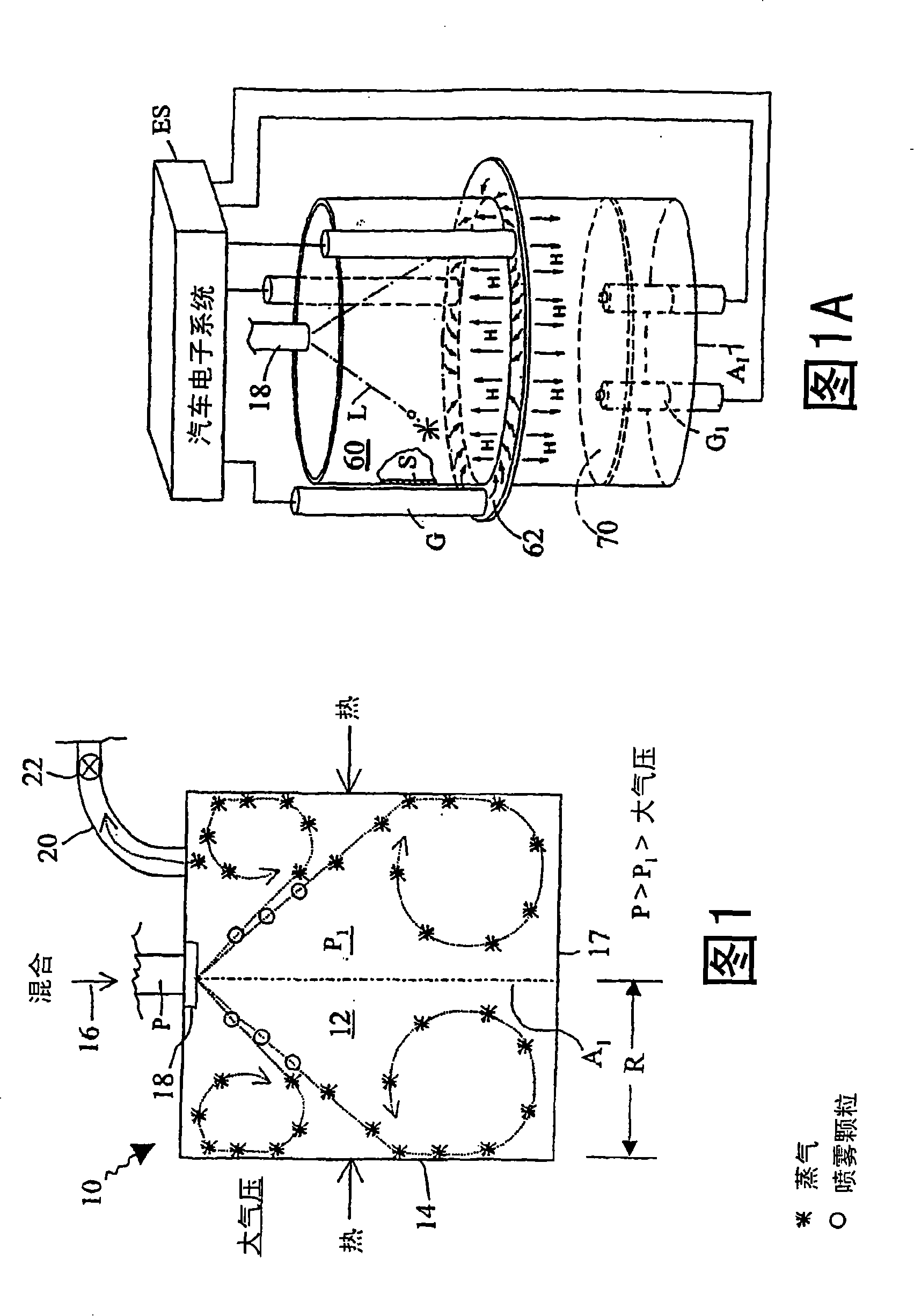

[0119] Referring to FIG. 1 , a vaporization chamber 10 vaporizes liquid fuel in a chamber 12 . The evaporation operation is the process by which liquid fuel particles are converted into a gaseous state in which very fine, dispersed residual liquid particles may also be suspended. For example, the lighter components of liquid fuel particles will be completely converted to gas, while the heavier components will be partially converted to gas, and the remaining extremely fine particles will have a large total area, which will facilitate rapid heating and combustion in the engine.

[0120] A closed pressure chamber, comprising a cylindrical wall 14 and end walls 15 , 17 , defines a volume 12 . As indicated by the arrows, the cylindrical wall 14 is heated by an external heat source. Liquid fuel 16 arrives at vaporization chamber 10 from a pressure source and is pulsed into volume 12 by injector 18 . Injector 18 injects liquid fuel from an orifice or set of orifices into volume 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com