Technique for processing guiding cylinder

A processing technology and a guide cylinder technology, applied in the processing technology field of the guide cylinder, can solve the problems of special structure and easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

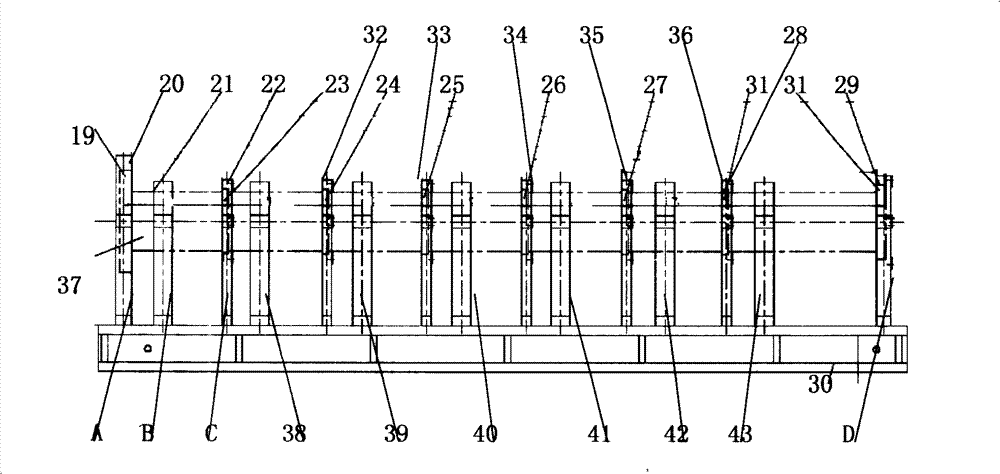

[0018] Now according to accompanying drawing, the present invention is further described, a kind of processing technology of guide cylinder, and its flow process is as follows:

[0019] 1. The processing flow of the continuous section:

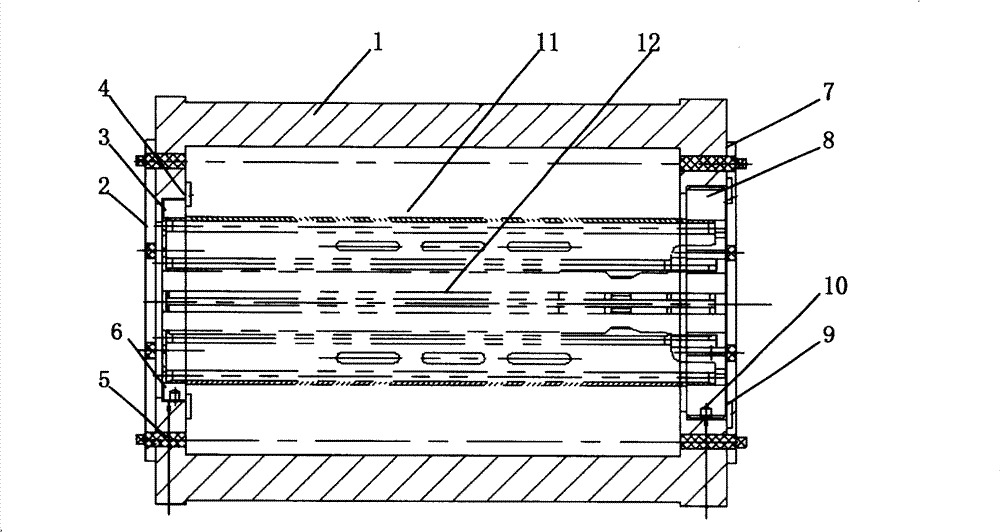

[0020] a. Install the template A2 on one side of the motherboard 1 first, and install the small flange 3 from the other side, then position it with the template A, and then position it with the small flange 3 through the positioning screw 6 and the small pressure plate 4, and then remove it Template A, then insert the double-hole tube 11 and C-shaped tube 12, install the large flange 8 from the other side in sequence, and position it with the template B7, then adjust the positioning screw 10 and the small pressure plate 9 to position the large flange, and then remove the template B, Determine the gap between the double-hole pipe 11 and the planes of the two flanges 3 and 8 to be 0.10-0.15;

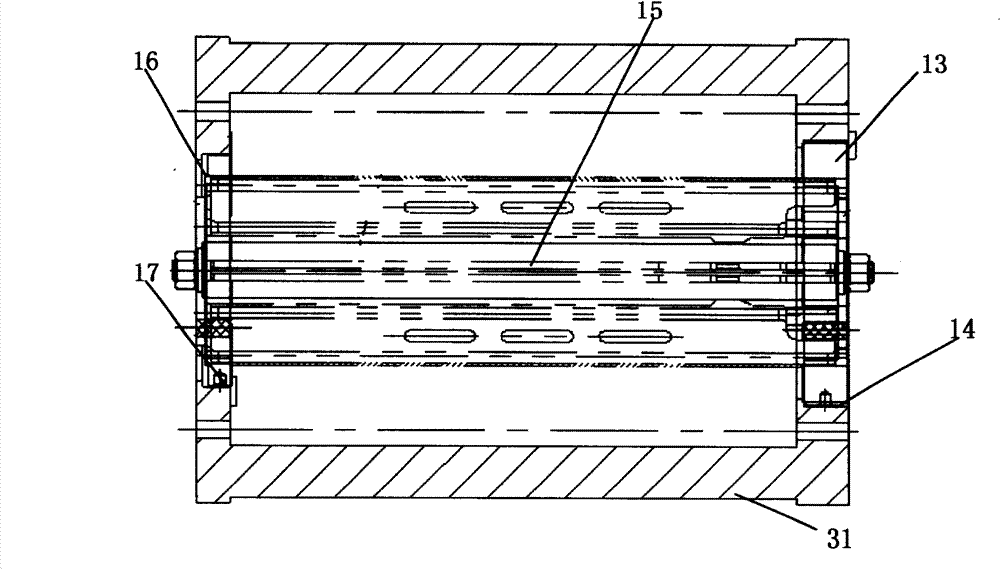

[0021] b. Then insert the template C13 on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com