Bicycle frame structure for automatic bicycle

An automatic two-wheeled vehicle and frame structure technology, which is applied in the directions of motor vehicles, bicycles, motorcycles, etc., can solve the problems of increased vehicle weight, inability to effectively achieve modular assembly methods, and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

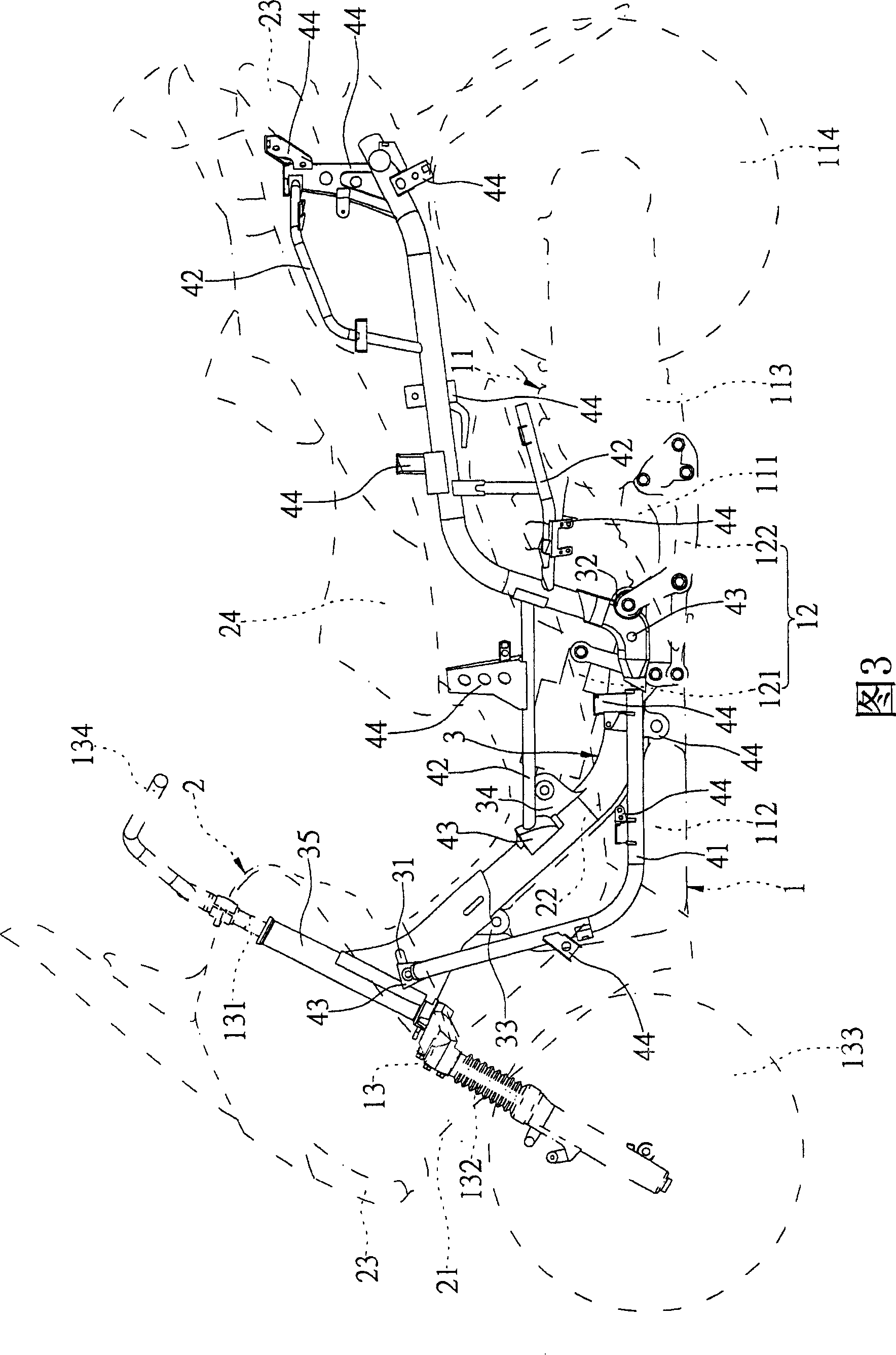

[0053] First of all, although it is shown that the frame structure of the present invention is applied to an automatic two-wheeled vehicle, the present invention is not limited to be applied to an automatic two-wheeled vehicle, and may also be applied to other types of scooter-type locomotives and shifting-type locomotives. , and powered vehicles. Power vehicles such as ATV (All-terrain vehicles, all-around off-road vehicles) and snow mobile vehicles.

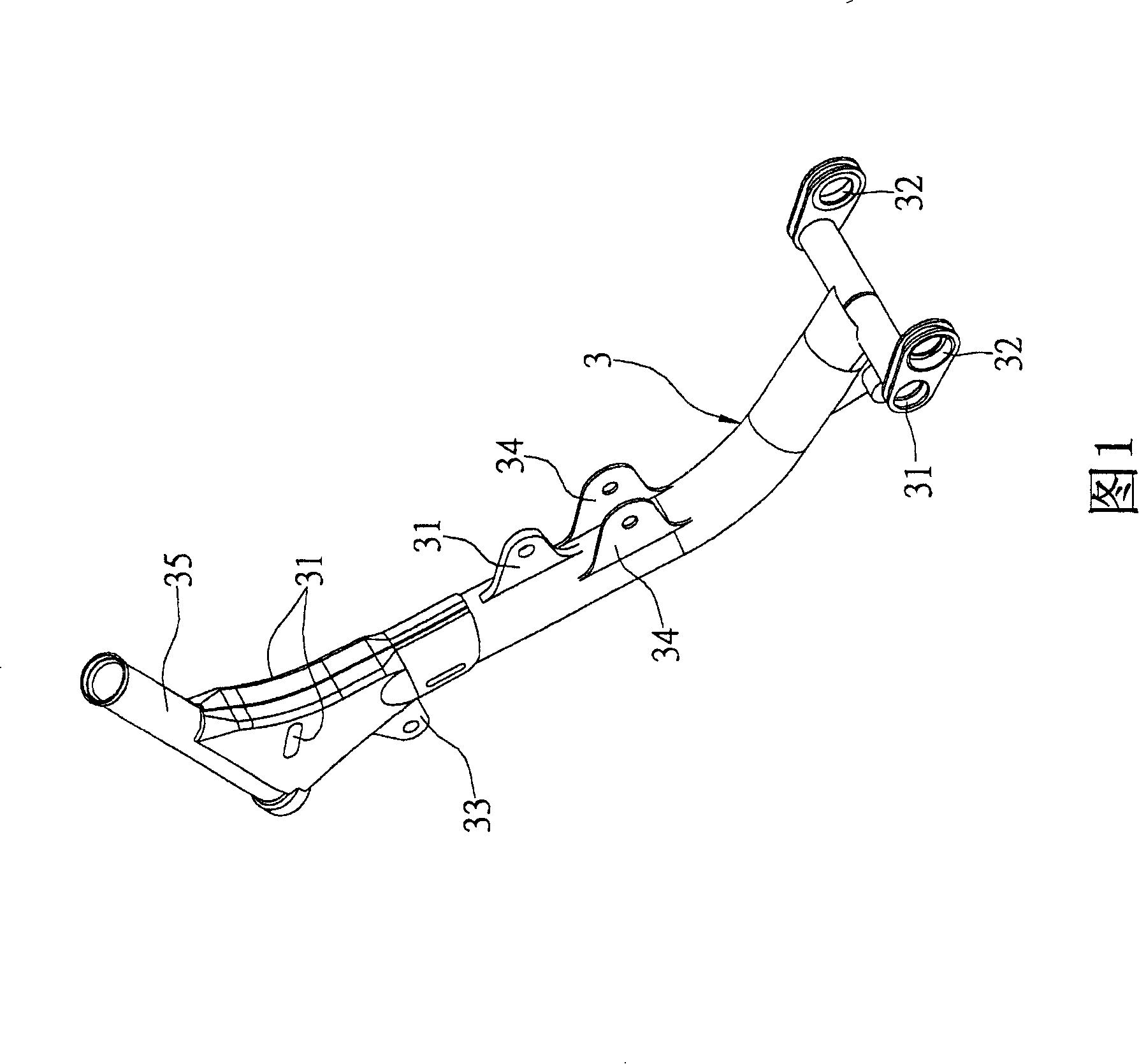

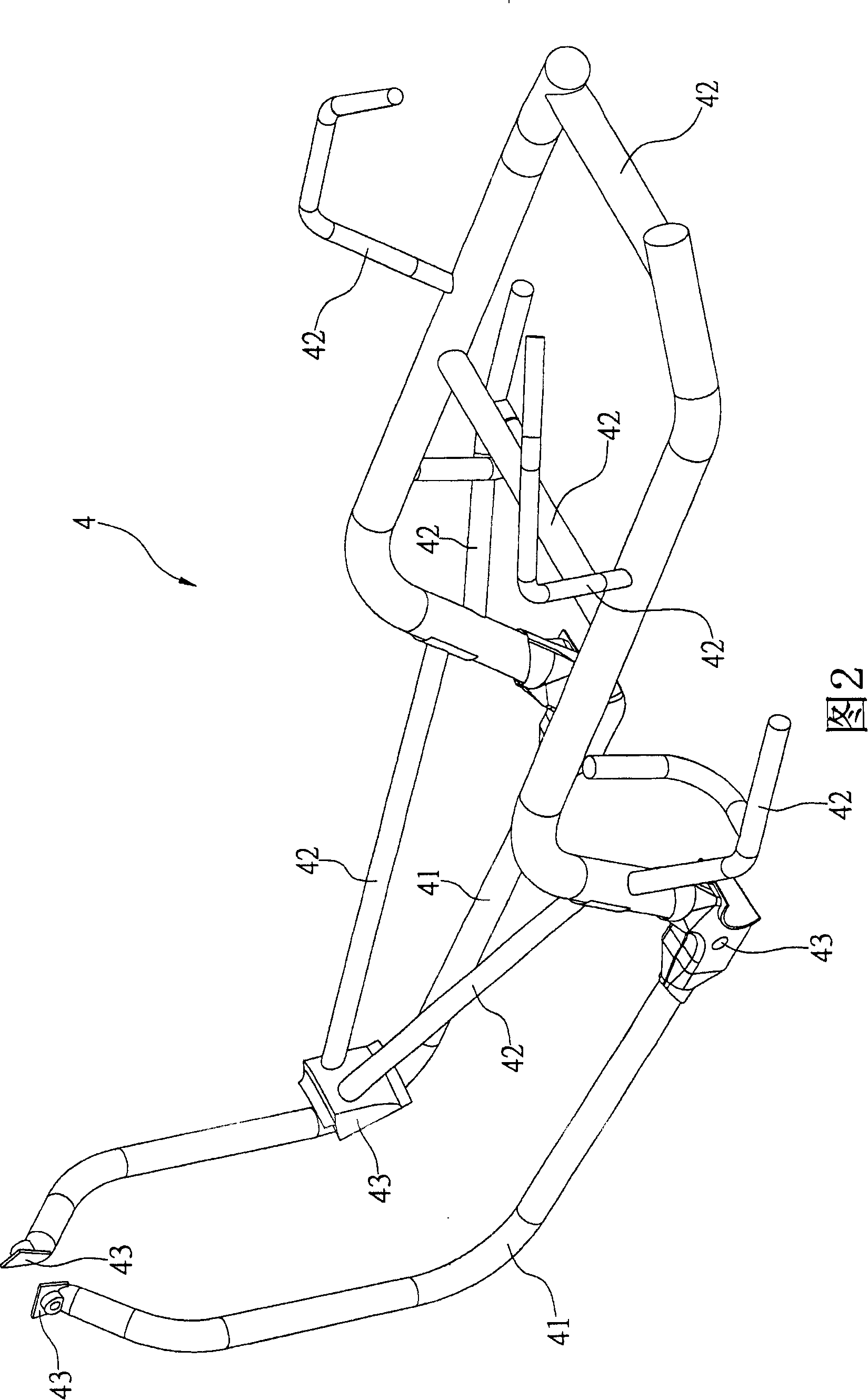

[0054] Please refer to Fig. 1, Fig. 2 and Fig. 3, the present invention is used to assemble the power control carrying device 1 and the vehicle body device 2 of the vehicle; the power control carrying device 1 has at least a power device 11, a carrying device 12, A driving control device 13 .

[0055] The power device 11 includes: an engine 111 , a fuel tank 112 , a transmission mechanism 113 attached to the engine 111 , and a rear wheel 114 pivotally connected to the transmission mechanism 113 .

[0056] The carrying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com