Sealing wool top coiling apparatus and method

A winding device and a technology for sealing tops, which are used in transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of high manual operation requirements, uneven packaging, low efficiency, etc., and solve the problem of high price. , the effect of improving labor productivity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

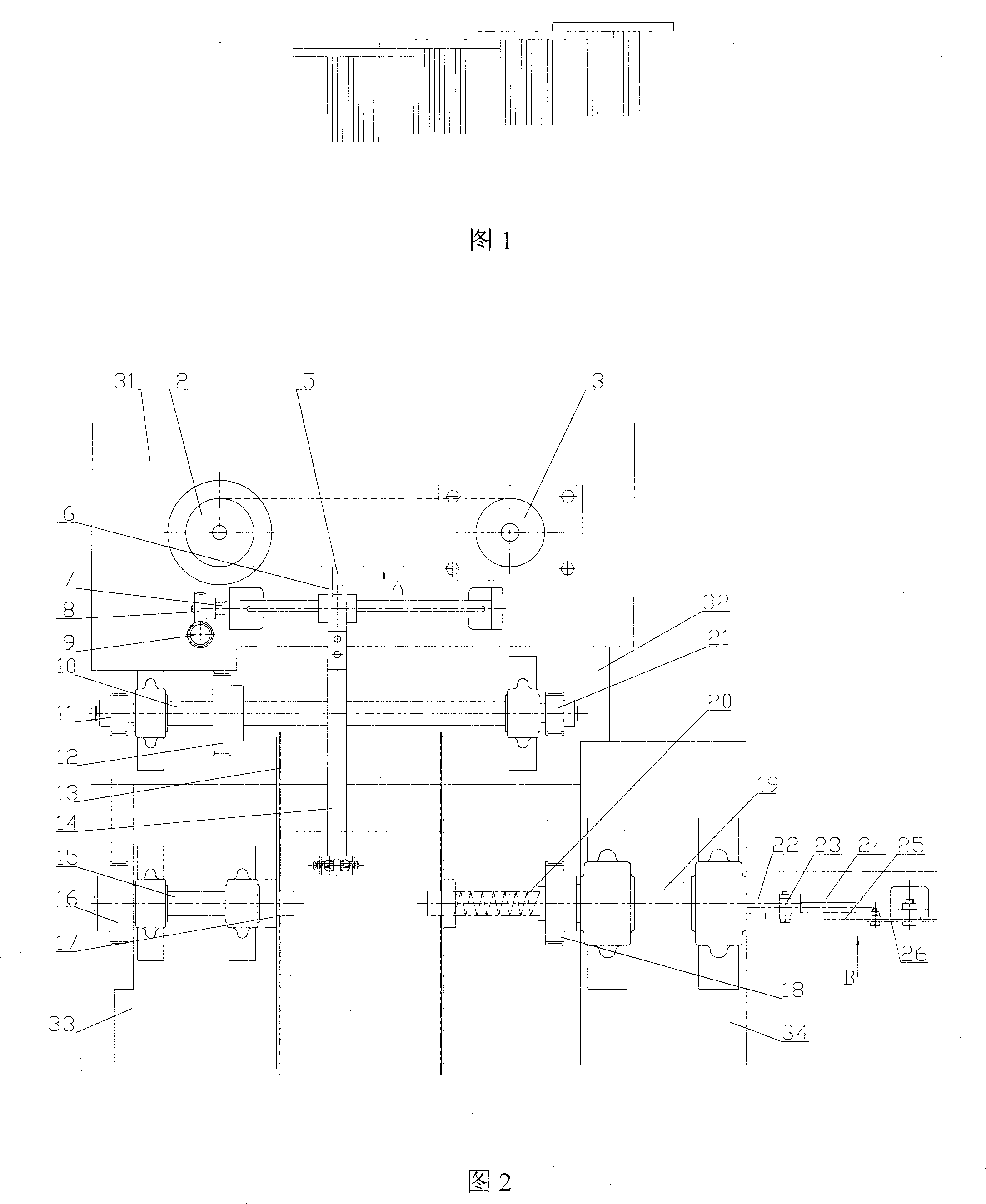

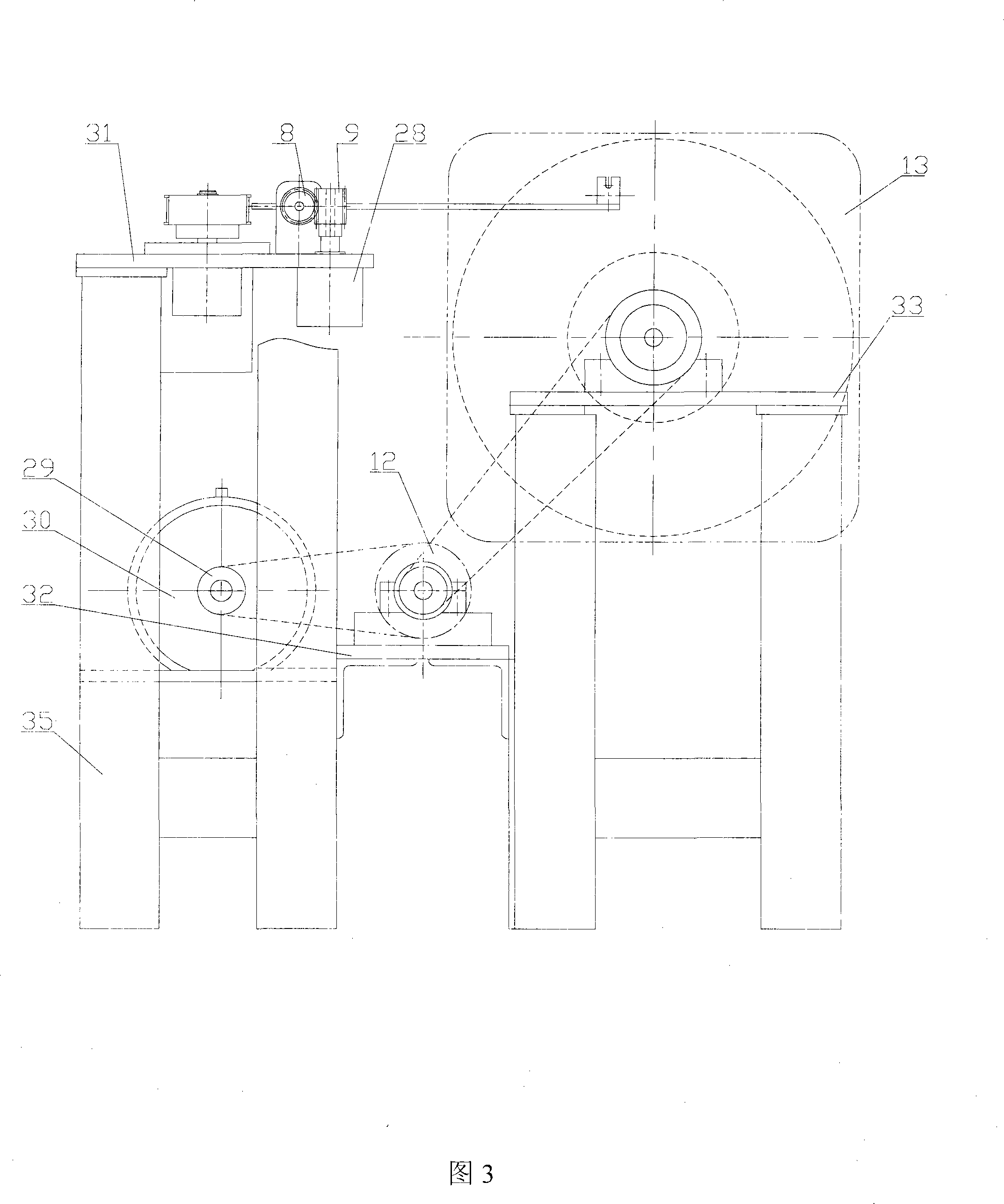

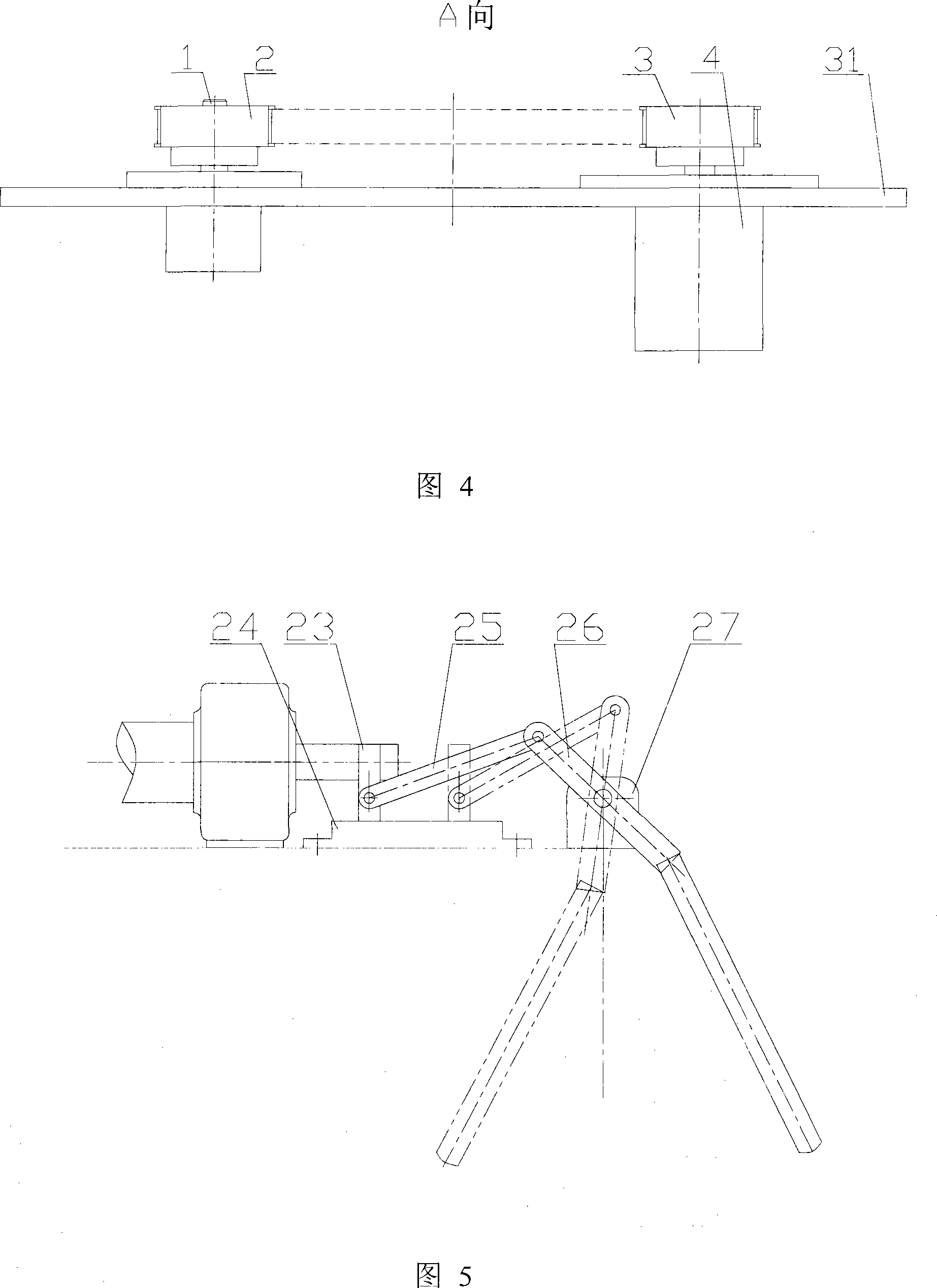

[0022] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

[0023] The sealing top winding device of the present invention (hereinafter referred to as the winding device) is divided into a mechanical structure part and a control part, and the general functional requirement is: even if the winding diameter of the bobbin changes layer by layer, the winding speed of the sealing top remains unchanged , and can realize the functions of constant tension winding, variable stroke winding and equal pitch winding. The functional requirements of the mechanical part of the winding device of the present invention are: the stroke is adjustable at 150-200 mm, the winding speed is adjustable at 8-9 m / min, and the sealing top is required to be wound at constant tension.

[0024] The mechanical structure part of the winding device of the present invention can be generally divided into two transmission routes: a reciprocating traverse tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com