Method and equipment for hanging iron tower

A hoisting method and technology for hoisting equipment, which are applied to hoisting devices, portable hoisting devices, cranes, etc., can solve the problems of limited conditions for erecting poles and towers of cranes, many workers in ground anchor pits, and high cost of erecting towers, so as to reduce labor intensity. , Small operating range, the effect of improving the efficiency of tower grouping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] According to the foundation size and site terrain, select the size of the fixed base of the lifting work platform and the connection fixture size of the foundation, and prepare the foundation height difference skid; Weight, size and parameters of the complete set, check the lifting conditions.

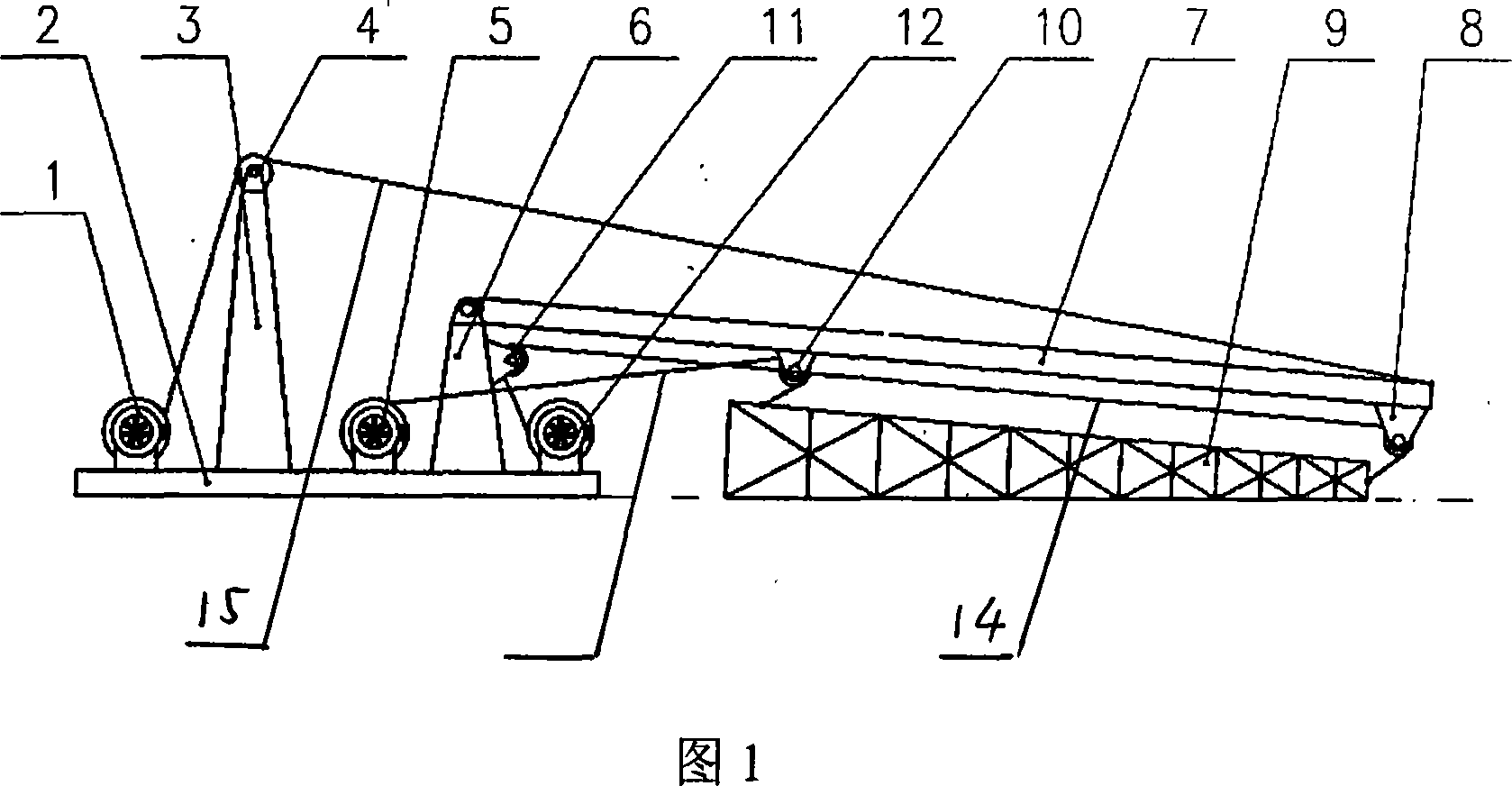

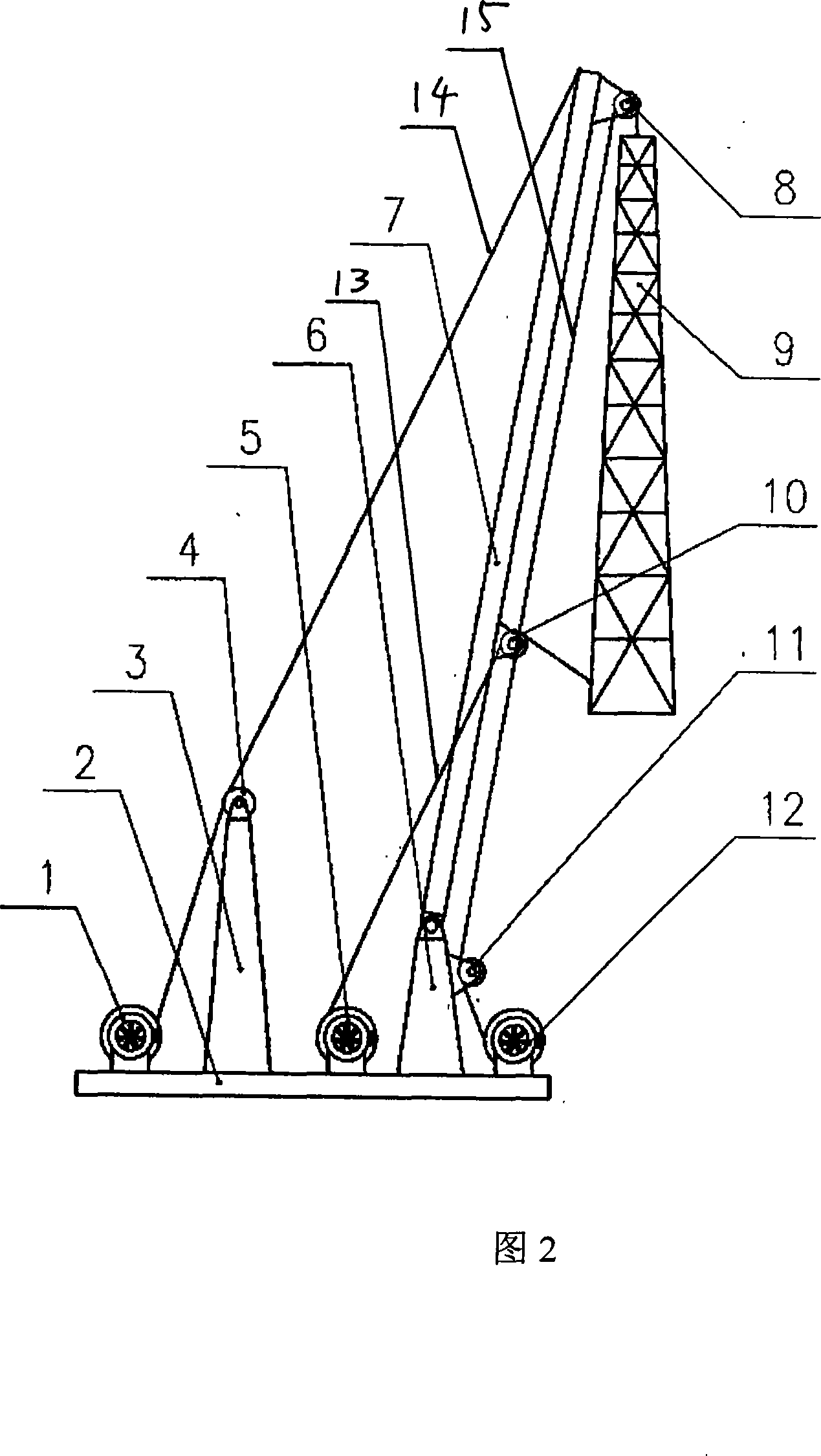

[0017] As shown in Figure 1, a lifting base 3, a boom base 6, a lifting winch 1, a traction winch 5, and a lifting winch 12 are installed on the lifting work platform 2, and the boom 7 is hinged on the boom base 6. Hoisting rope 14 is fixedly connected with boom 7 through hoisting winch 1, hoisting fixed pulley 4; Iron tower 9 and boom 7 are placed in the ground hoisting state shown in Fig. 2; Traction winch 5, traction rope 13 pass traction wheel 10 and iron tower 9 The bottom of the iron tower 9 is fixedly connected; the hoisting rope 15 is fixedly connected to the top of the iron tower 9 through the hoisting winch 12, the hoisting fixed pulley 11, and the hoisting pulley 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com