Servo-system analog loading control device

A servo system and control device technology, applied in simulators, electric controllers, general control systems, etc., can solve problems affecting the control performance and loading accuracy of the loading system, and achieve high repetition frequency, wide torque range, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

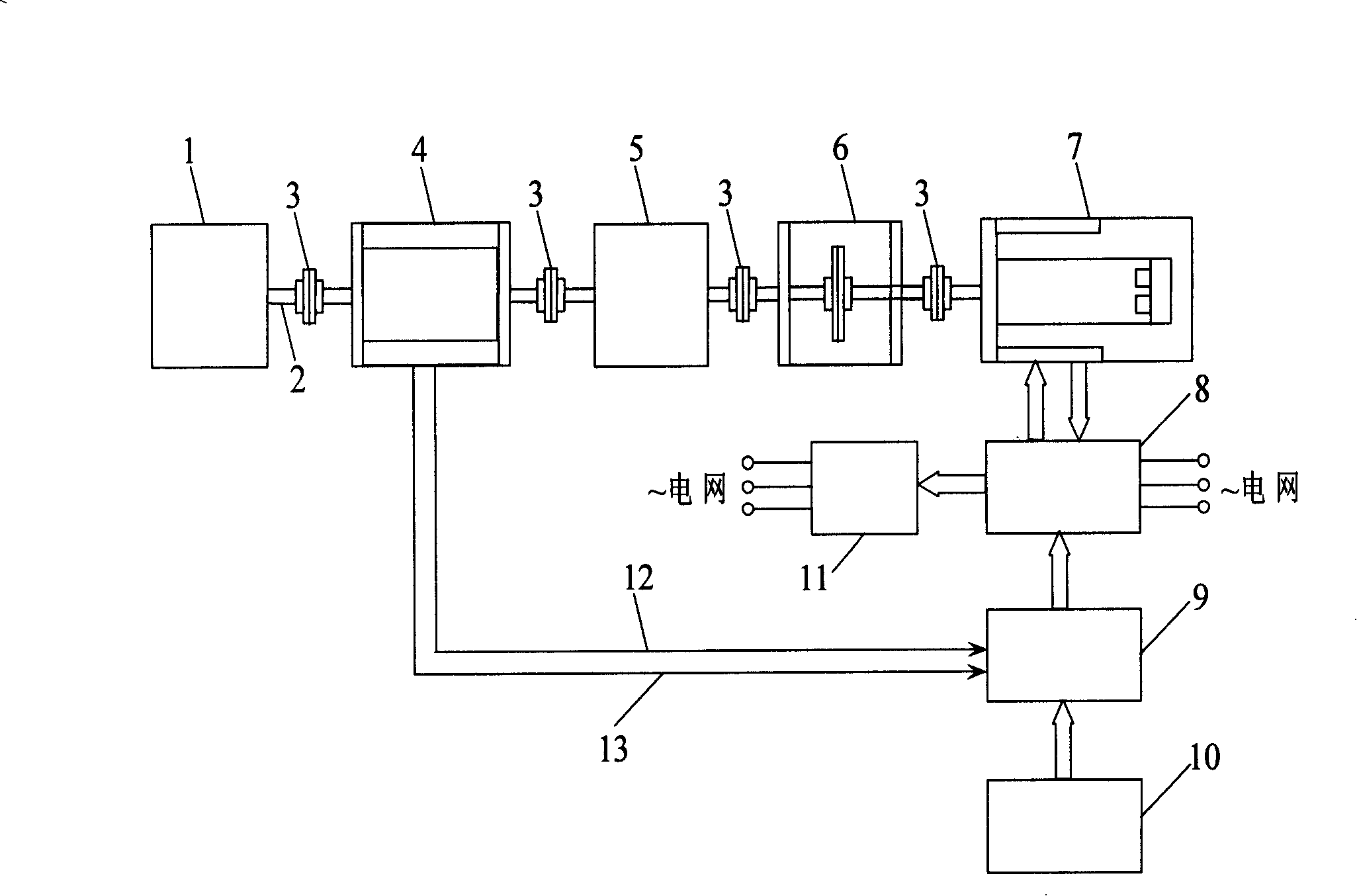

[0010] combined with figure 1 , the servo system analog loading control device of the present invention, the output shaft 2 of the servo system 1 is mechanically connected with the torque speed sensor 4, the speed reducer 5, the inertia disk 6, and the loading motor 7 in turn through the shaft connection 3, and the loading motor 7, the motor The driver 8, the torque controller 9, and the instruction computer 10 are connected with electrical signals in sequence, the motor driver 8 is connected with the inverter 11 with electrical signals, and the torque controller 10 is connected with the torque feedback signal 12 and the rotational speed feedback signal 13 output by the torque rotational speed sensor 4 connect.

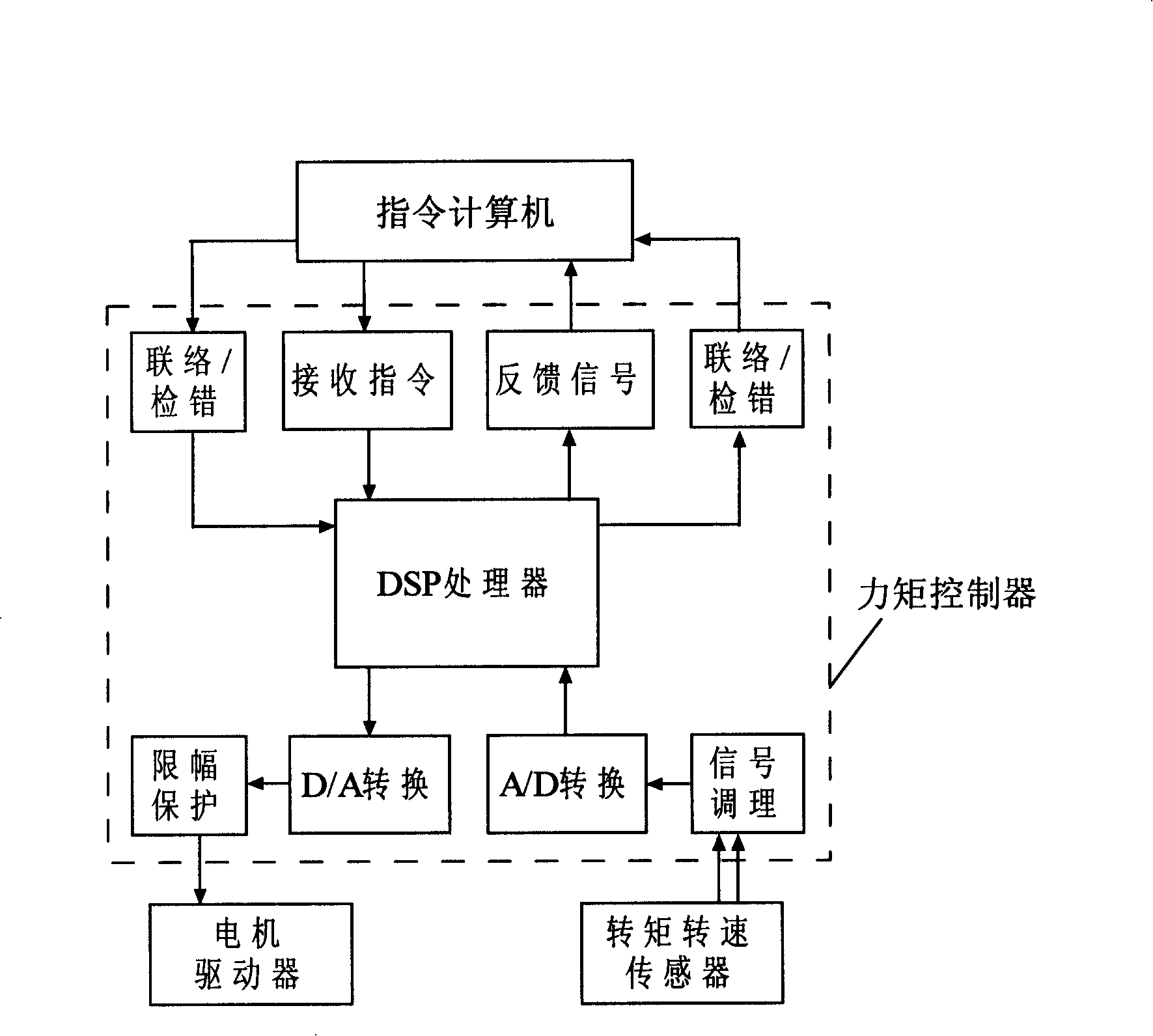

[0011] Its working process is: command computer 10 as a given link, torque ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com