Leadless crystal glass

A crystal glass and oxide technology, applied in the field of environmentally friendly crystal glass, can solve the problems of high price and uneconomical, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

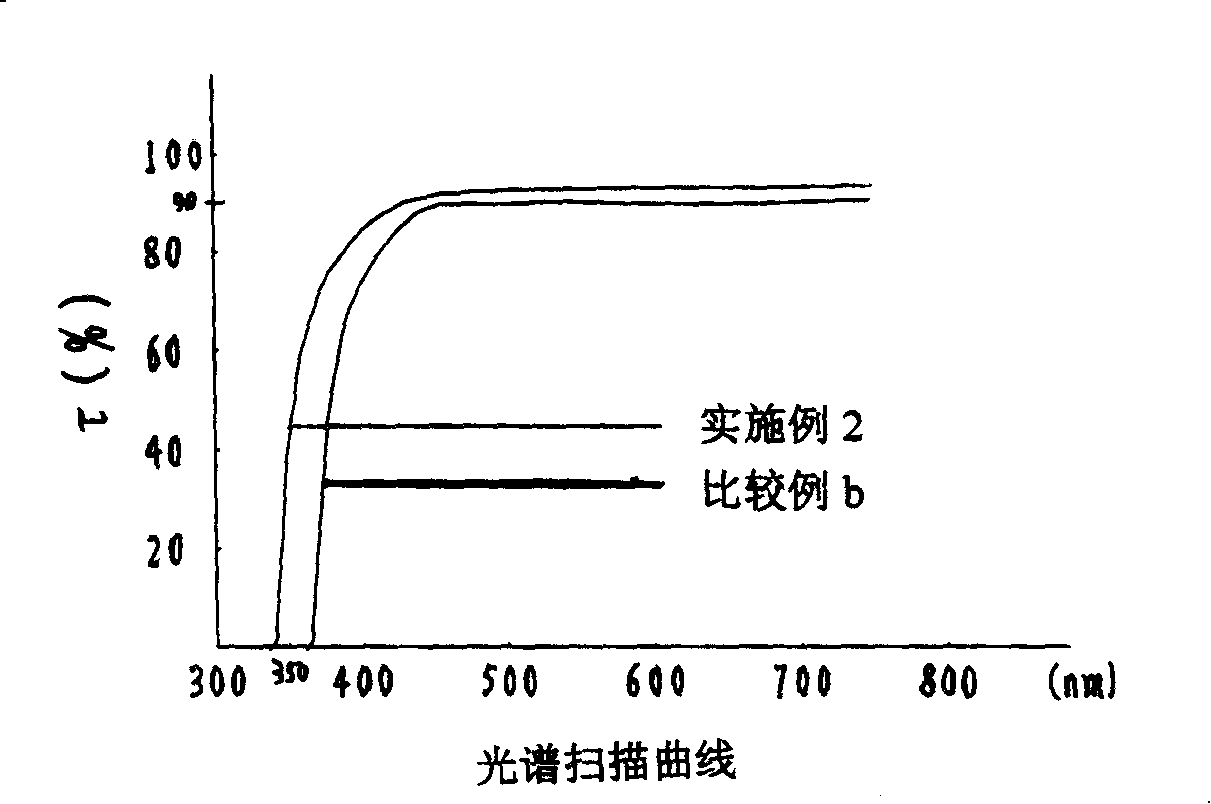

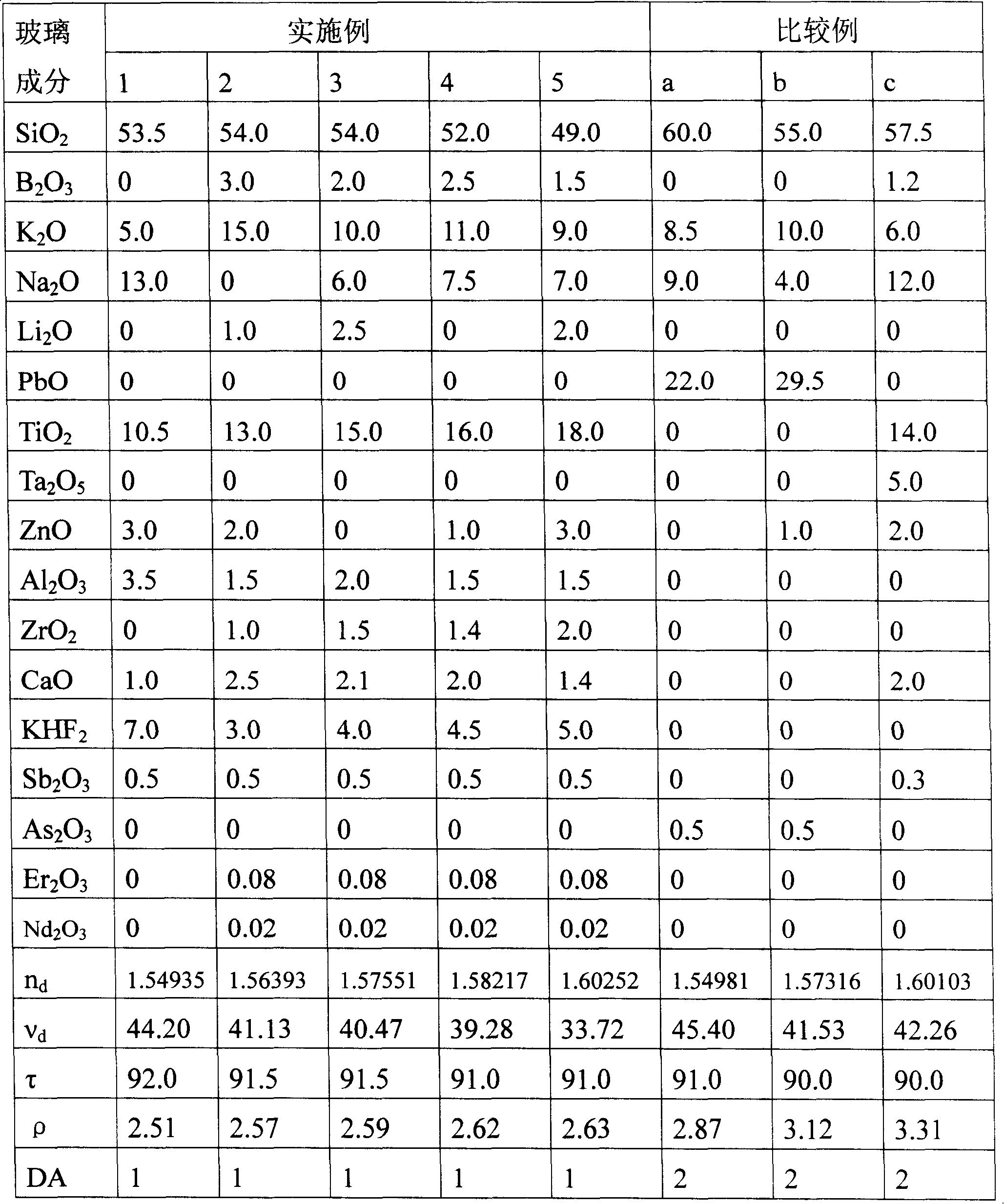

[0039] The present invention provides 5 embodiments and 3 comparative examples. Embodiment 1 to embodiment 5, the glass composition (weight percentage) of comparative example a to comparative example c, optical constant refractive index (n d ), dispersion coefficient (v d ), white light transmission (τ), glass specific gravity (ρ) and acid resistance (DA) properties are listed in Table 1.

[0040] Table 1

[0041]

[0042] In order to melt the glasses of Examples 1 to 5 and the glasses of Comparative Examples a to c, various oxides, nitrates, carbonates, etc. used in this type of glass are formulated into batch materials, and according to the melting characteristics of the glass, Add the chemical materials into the platinum crucible at a temperature of 1200°C to 1300°C, stir at a temperature of 1350°C to 1400°C, clarify for 3 to 4 hours, then lower it to a temperature suitable for molding, and pour it into a preheated mold Subsequent annealing forms the glass into a prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com