Method for preparing ultra-fine reduction dyestuff

A dye and ultrafine crushing technology, which is applied in the direction of organic dyes, can solve the problems of low crushing efficiency, high energy consumption, and long ultrafine crushing time, and achieve the effects of long grinding time, high energy consumption, and reduced energy consumption of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of superfine vat dyes, comprising the following steps:

[0030] a. Put the vat dye, dispersant and water into the one-way rotary ball mill, and perform ball milling to mix into a slurry material and pre-disperse;

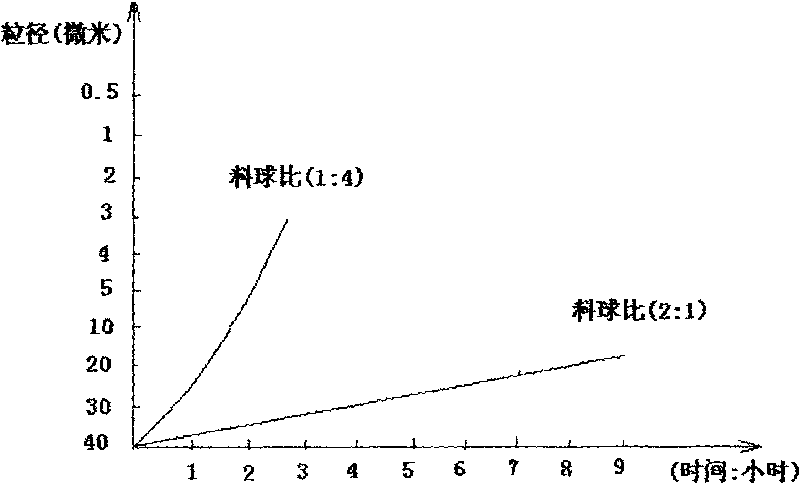

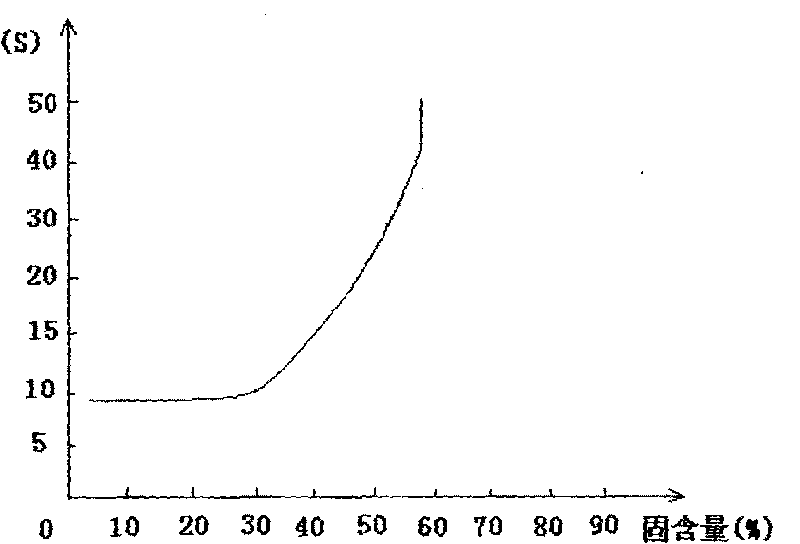

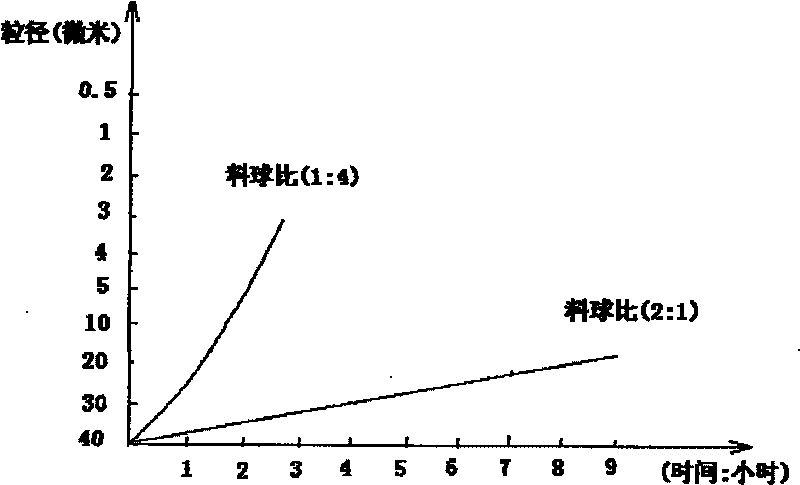

[0031]b. Add defoamer to the pulverized mixed material, and carry out superfine pulverization in a bidirectional rotating ball mill. Vat dyes are filter cakes or dry products of filter cakes after pressure filtration of raw dyes in the dye manufacturing process. The dispersant is sodium methylene naphthalene sulfonate dispersant: dispersant MF, dispersant CNF or dispersant CS. The mass ratio of the vat dye to the dispersant is 1:0.5, and the solid content of the mixed material after adding water reaches 20%. The grinding medium in the ball mill described in step a is ceramic beads, glass beads, zirconia beads, quartz sand or pebbles with a diameter of 5 mm, the mixing pre-dispersion time is 20 minutes, the grinding temperature is 5 °C, ...

Embodiment 2

[0033] A preparation method of superfine vat dyes, comprising the following steps:

[0034] a. Put the vat dye, dispersant and water into the one-way rotary ball mill, and perform ball milling to mix into a slurry material and pre-disperse;

[0035] b. Add defoamer to the pulverized mixed material, and carry out superfine pulverization in a bidirectional rotating ball mill. Vat dyes are filter cakes or dry products of filter cakes after pressure filtration of raw dyes in the dye manufacturing process. Dispersants are lignosulfonate dispersants: synthetic sodium lignosulfonate MS, modified sodium lignosulfonate, dispersant M9, dispersant M10, dispersant M13 or dispersant M15. The mass ratio of the vat dye to the dispersant is 1:4, and the solid content of the mixed material after adding water reaches 55%. The grinding medium in the ball mill described in step a is ceramic beads, glass beads, zirconia beads, quartz sand or pebbles with a diameter of 50 mm, the mixing pre-dispe...

Embodiment 3

[0037] A preparation method of superfine vat dyes, comprising the following steps:

[0038] a. Put the vat dye, dispersant and water into the one-way rotary ball mill, and perform ball milling to mix into a slurry material and pre-disperse;

[0039] b. Add defoamer to the pulverized mixed material, and carry out superfine pulverization in a bidirectional rotating ball mill. Vat dyes are filter cakes or dry products of filter cakes after pressure filtration of raw dyes in the dye manufacturing process. The dispersant is sodium methylene naphthalene sulfonate dispersant: dispersant MF, dispersant CNF or dispersant CS. The mass ratio of the vat dye to the dispersant is 1:3, and the solid content of the mixed material after adding water reaches 45%. The grinding medium in the ball mill described in step a is ceramic beads, glass beads, zirconia beads, quartz sand or pebbles with a diameter of 30 mm, the mixing pre-dispersion time is 10 hours, the grinding temperature is 50 ° C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com