High output MR damper

A magneto-rheological damper with high output technology, applied in building components, shockproof, etc., can solve the problems of complex magnetic circuit structure, difficulty, and low adjustable range of damping force, so as to simplify the composite magnetic circuit structure and ensure real-time effective The effect of sexiness, simplification of design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

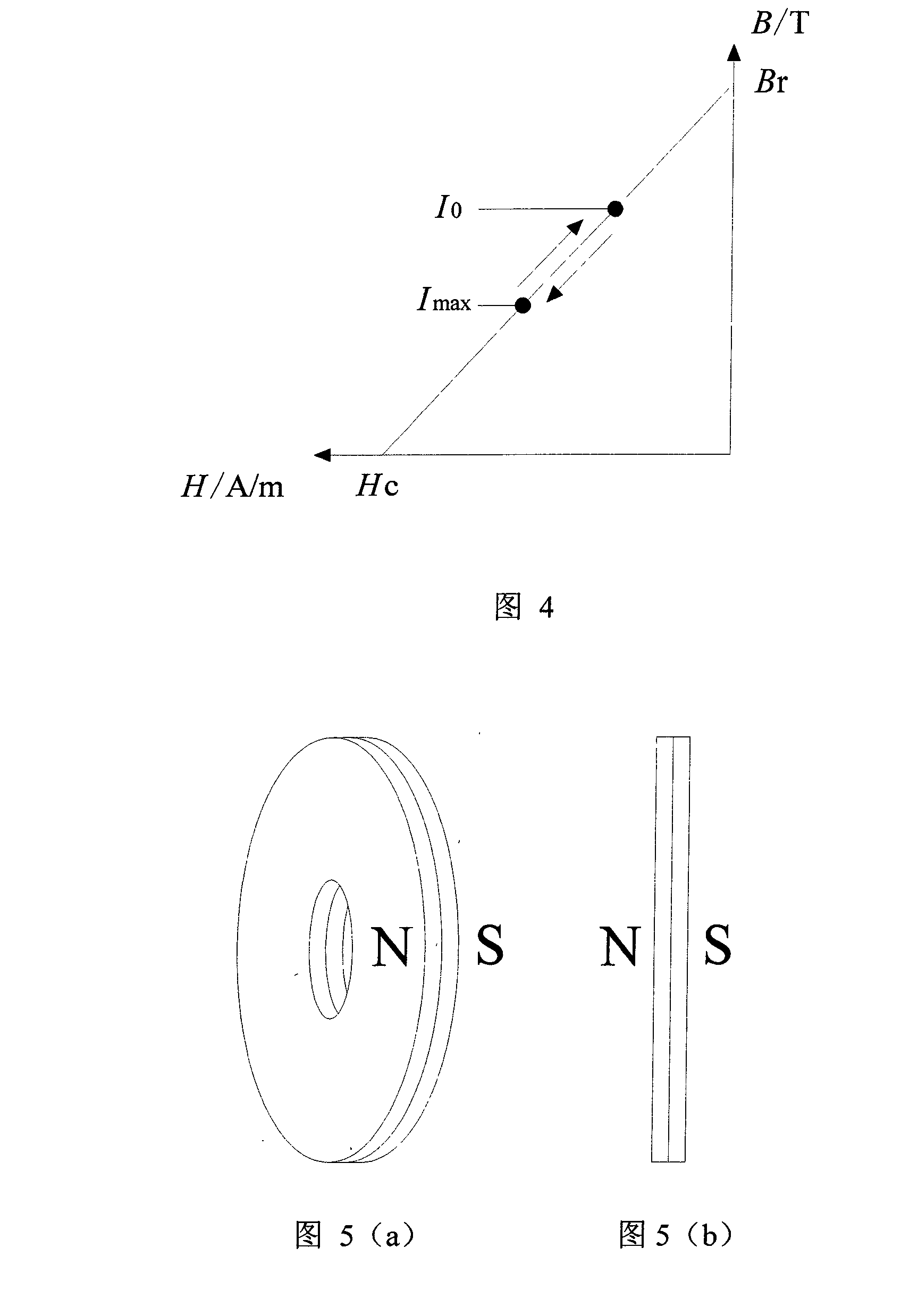

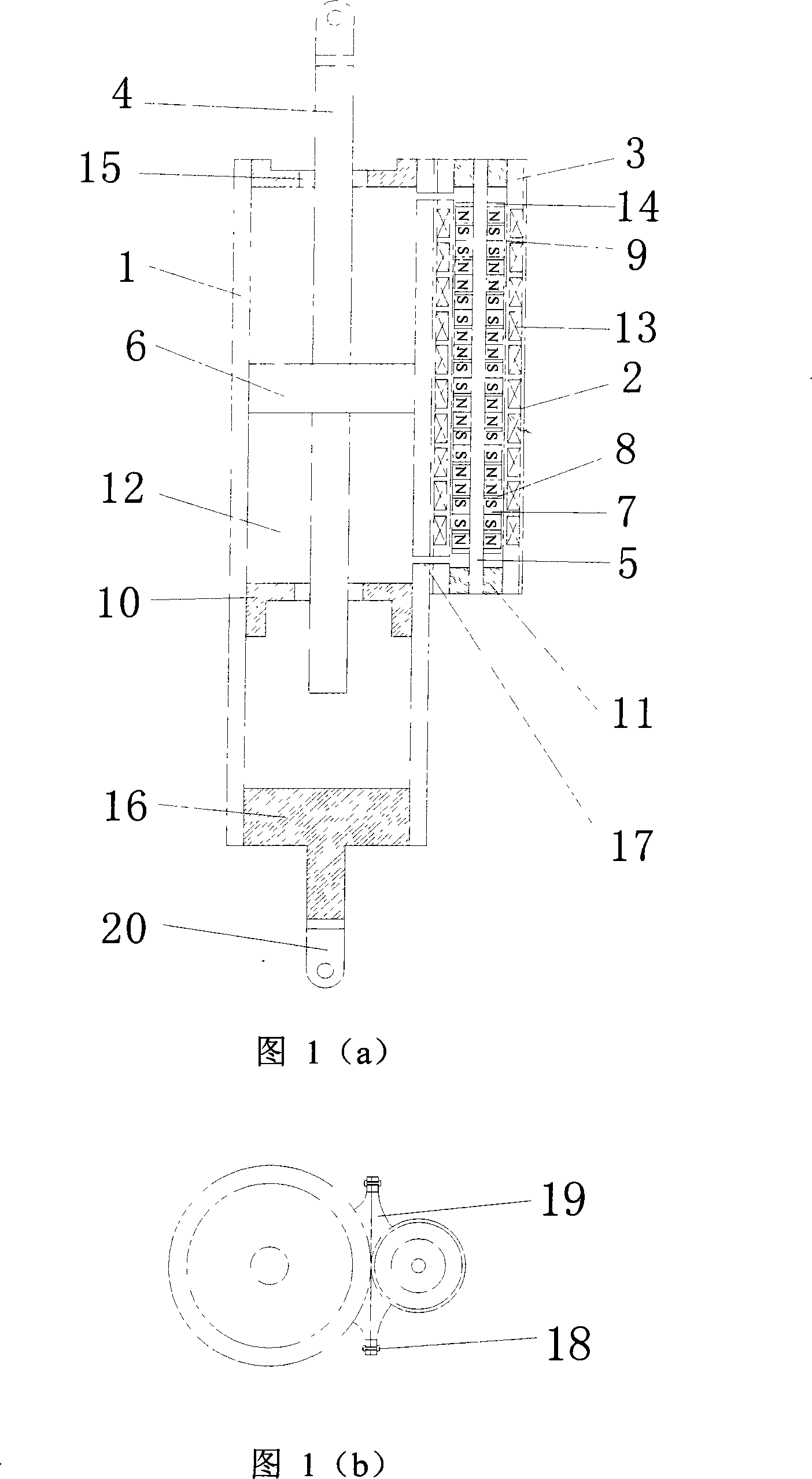

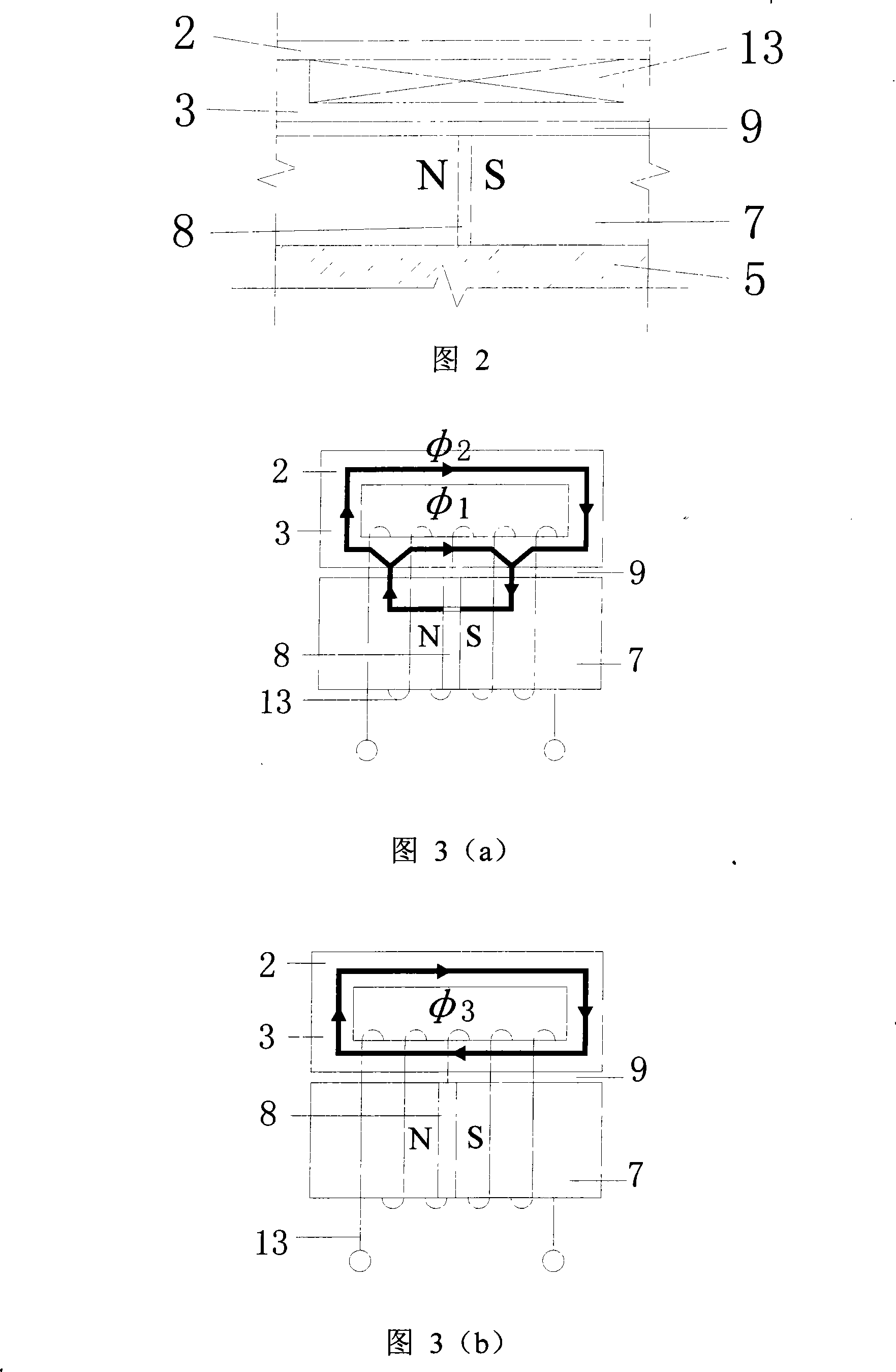

[0022] The high-output magneto-rheological damper includes a main cylinder cylinder 1, an auxiliary cylinder outer cylinder 2, an auxiliary cylinder inner cylinder 3, a main cylinder piston rod 4, an auxiliary cylinder piston rod 5, a main cylinder piston disc 6, an auxiliary cylinder Cylinder piston disc 7, permanent magnet sheet 8, damping channel 9, main cylinder end cover 10, auxiliary cylinder end cover 11, magnetorheological fluid 12, excitation coil 13, stainless steel resistance disc 14, sealing ring 15, bottom cover 16, channel 17. Bolt 18, support 19 and earring 20. The master cylinder piston disc 6 is set behind the master cylinder piston rod 4 to form the master cylinder piston. The master cylinder end cover 10 is sealed and fixed with the master cylinder barrel 1. After the master cylinder piston is put into the master cylinder b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com