Engineering machinery electro-fluid automatic gear box shifting controller and method

A technology for automatic gear shifting and construction machinery, which is applied in the direction of transmission control, mechanical equipment, and components with teeth. It can solve the problems that the control program cannot intervene in it and the control is complicated, so as to achieve good shifting quality and balance Economical and comfort-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

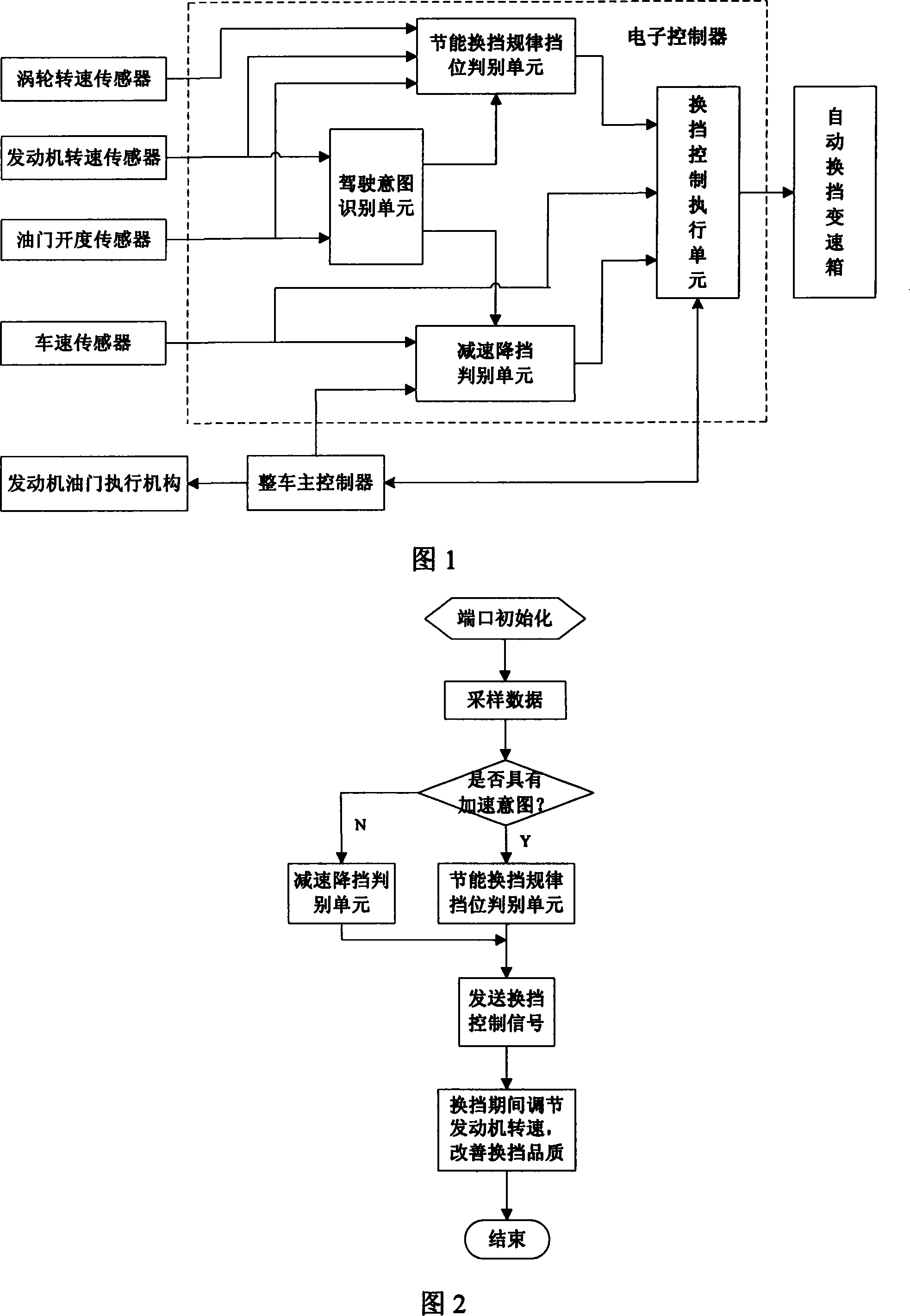

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0024] As shown in Figure 1, the engine speed sensor, the engine throttle opening sensor and the vehicle speed sensor input signals to the driving intention recognition unit in the electronic controller through the input port of the electronic controller; the engine speed sensor, the engine throttle opening sensor and the variable speed sensor The torque sensor turbine speed sensor inputs the signal to the energy-saving gear shift regular gear discrimination unit in the electronic controller through the input port of the electronic controller; the vehicle speed sensor inputs the signal to the deceleration downshift of the electronic controller through the input port of the electronic controller The discrimination unit and the shift control execution uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com