Rapid water heater

A water heater, fast technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of uneven heating of the transducer plate, unreasonable connection, insufficient contact, etc., to achieve good heat dissipation, The effect of sufficient space utilization and sufficient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

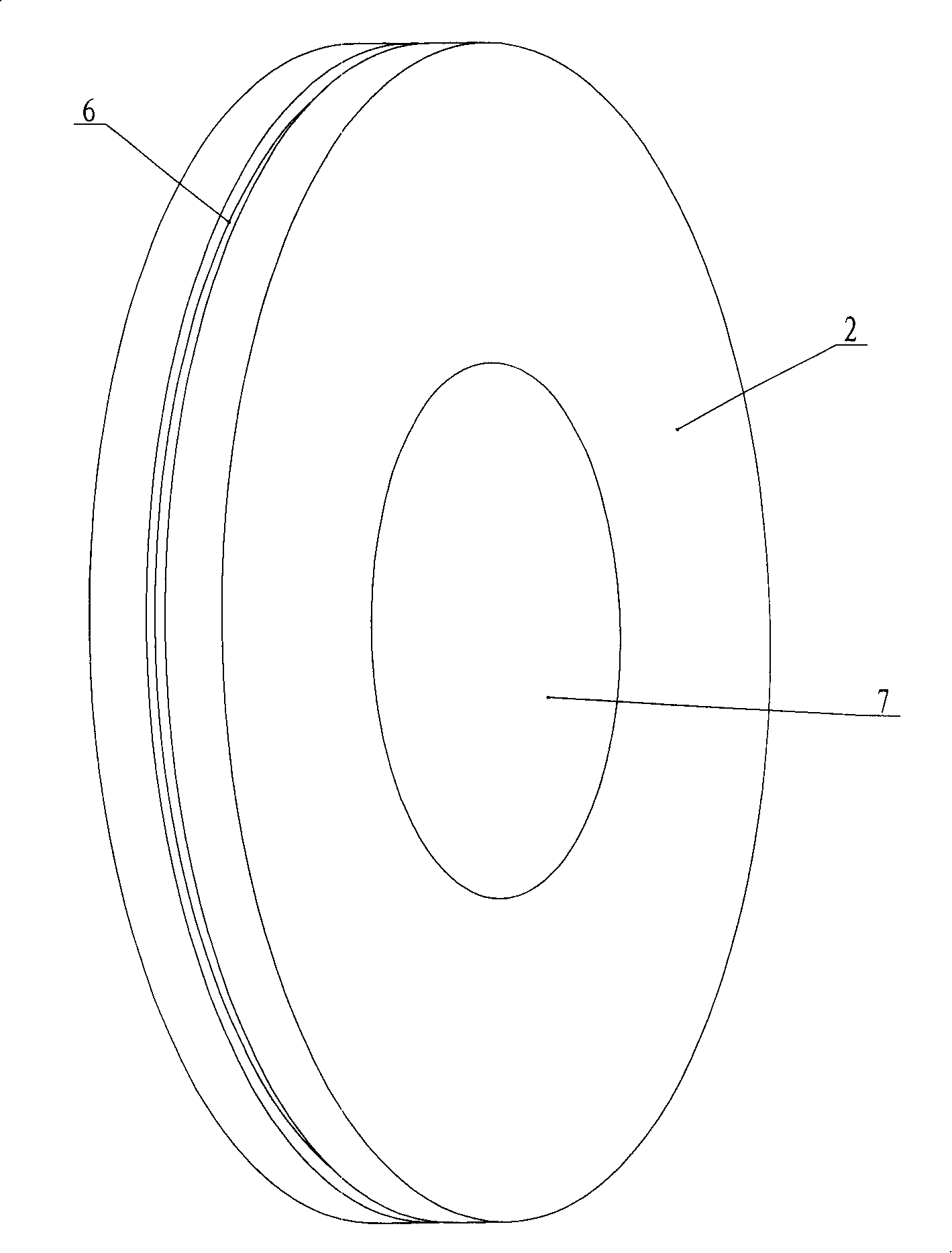

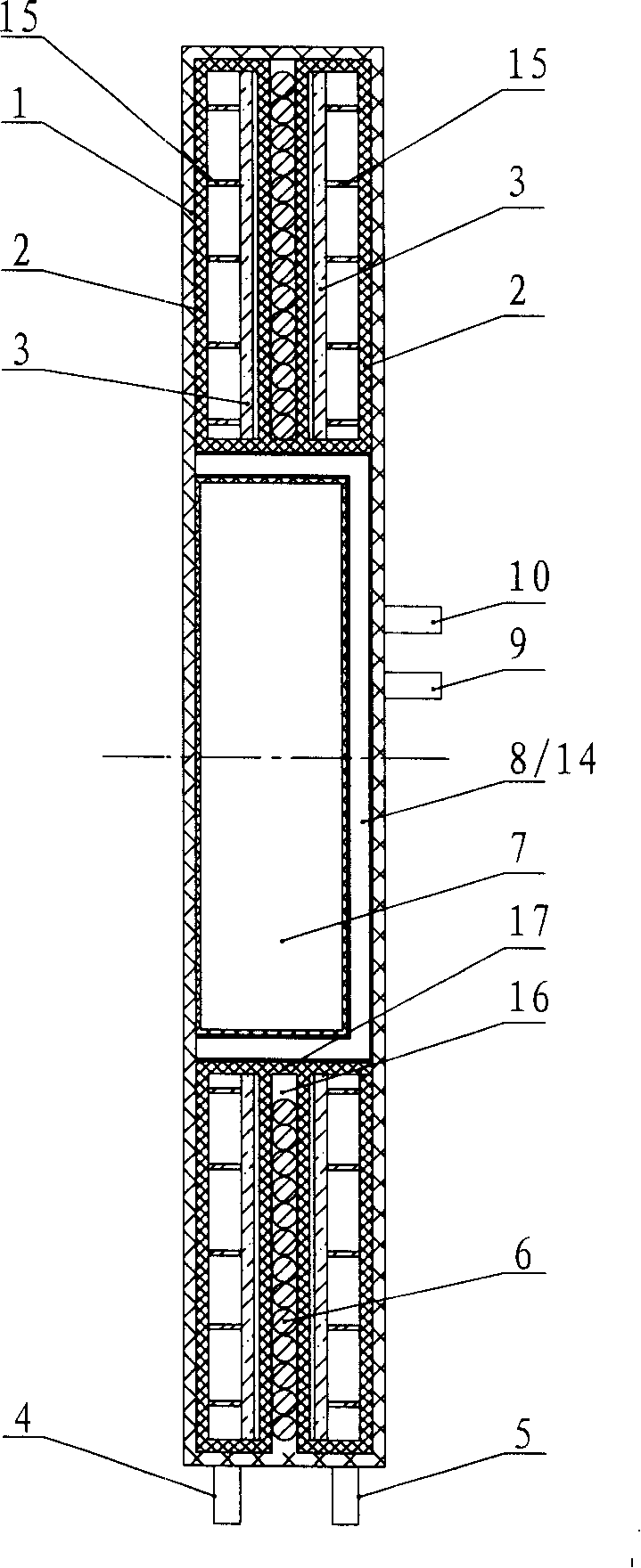

[0042] figure 1 and figure 2 The electromagnetic induction heating instant water heater shown includes a housing 1 and a water tank 2 arranged in the housing 1, a heating coil 6 and a power frequency converter 7. The water tank 2 is provided with a water inlet pipe 4 and a water outlet pipe 5. The water tank 2 is provided with an eddy current heating device, and the heating coil 6 is electrically connected to the power frequency converter 7; more specifically:

[0043] The water tank 2 , the eddy current heating element and the heating coil 6 are annular, and the heating coil 6 is located outside the water tank 2 and arranged corresponding to the eddy current heating element.

[0044] An accommodating cavity 14 is formed at the center of the water tank 2, and the accommodating cavity 14 is formed by setting an annular support portion 17 between two water tanks. Inside.

[0045] The accommodation cavity 14 is a closed cavity, and a cooling water inlet 9 and a cooling water...

Embodiment 2

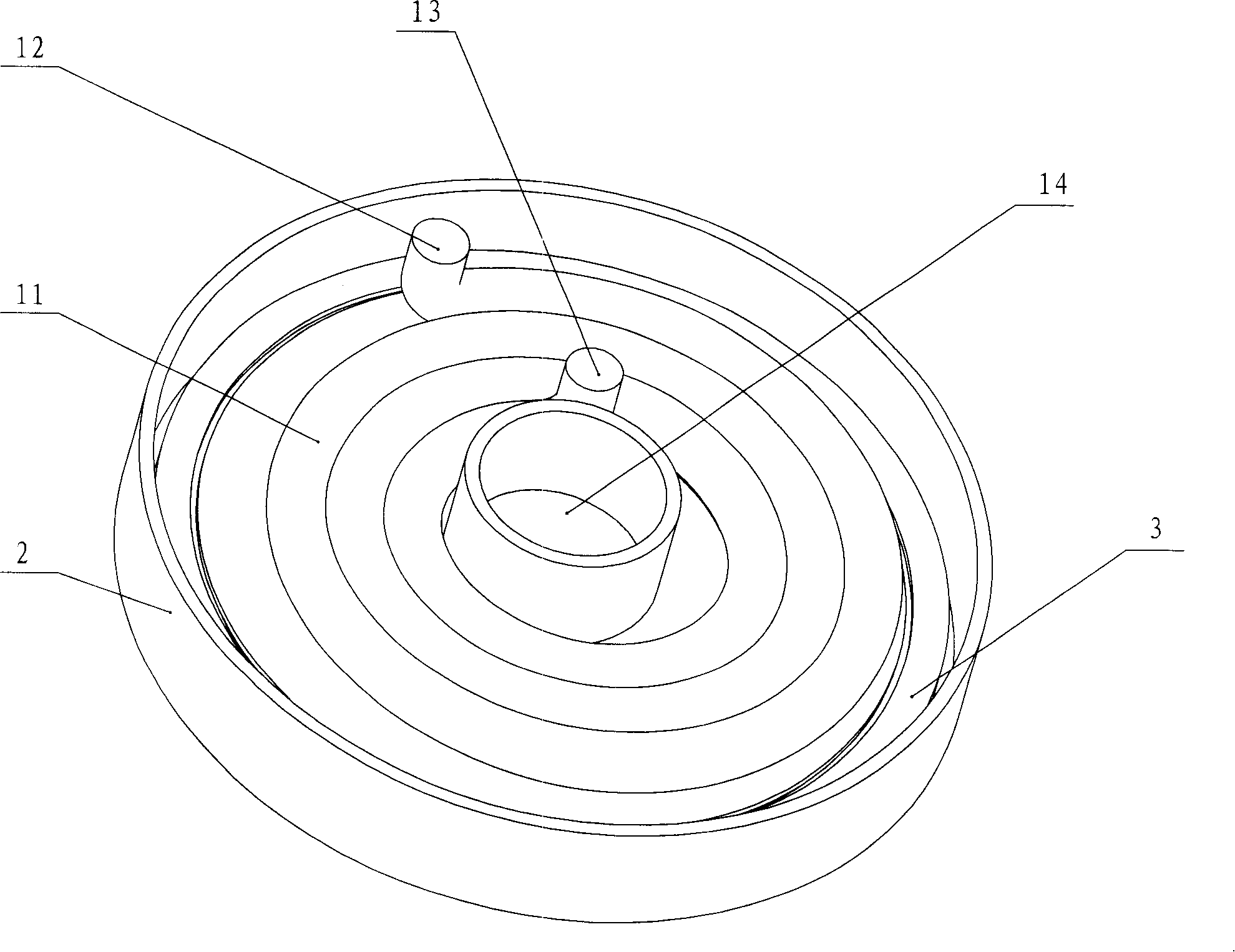

[0056] Such as image 3 As shown, the eddy current heating device includes a flat annular sheet 3 and a heat conducting spiral coil 11 in thermal contact with the flat annular sheet 3 to enhance the heat exchange effect. One end 12 of the heat-conducting spiral coil 11 is connected with the water outlet pipe 5, and the other end is led to the outside of the water tank 2 through 13 as a hot water outlet, so as to prolong the residence time of the water flow in the water tank 2 and fully exchange heat (see Fig. 4 ( c), 4(d)); or one end 12 of the heat-conducting spiral tube 11 is connected to the cooling water outlet 10, and the other end is opened in the water tank 2, so that the cooling water can be led to the water tank to make all the water flow in the water tank flow to prevent the formation of dead water areas; in order to enhance the heat transfer effect, the heat-conducting spiral coil 11 is made of water pipes with excellent thermal conductivity such as copper water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com