Bimetal sheet type optical fiber microbending temperature sensor

A temperature sensor, bimetal technology, applied in thermometers, using optical devices to transmit sensing components, thermometers based on material expansion/contraction, etc., can solve the problems of poor stability, low sensitivity, large volume, etc., to change bending Loss, good reliability, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

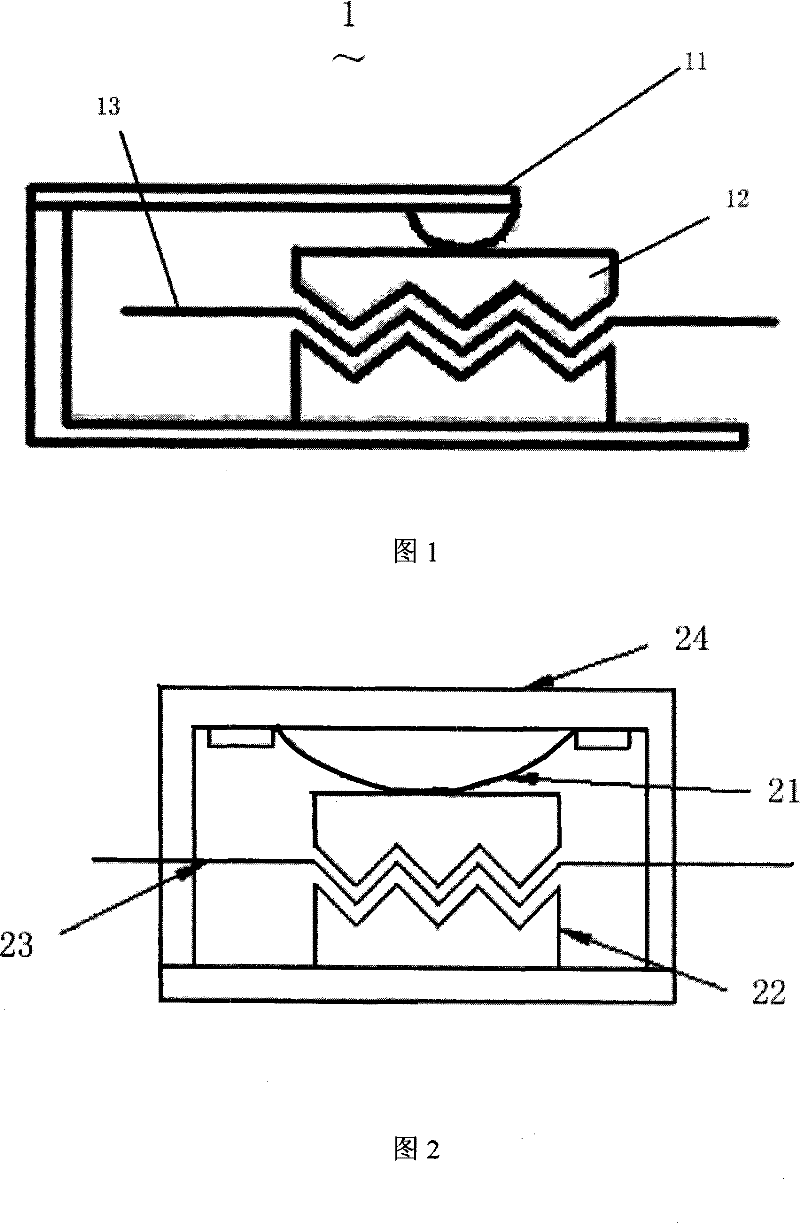

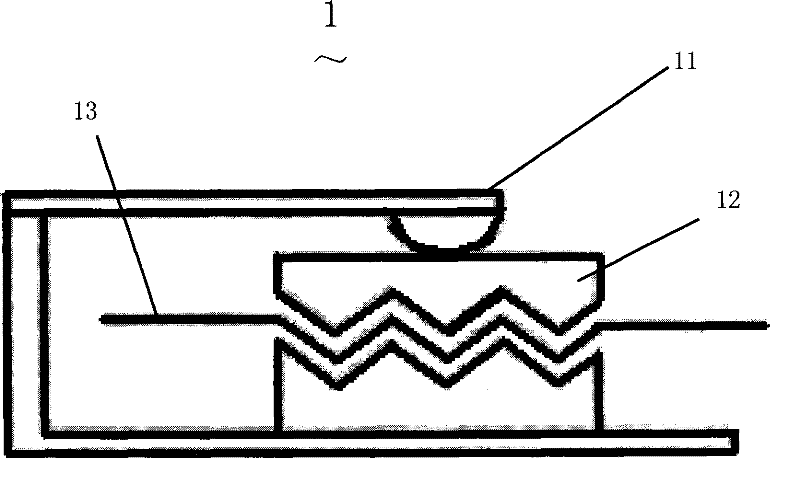

[0019] see figure 1 , the present invention provides a bimetallic microbending optical fiber temperature sensor 1, which comprises two optical fiber microbending deformers 12 composed of two oppositely arranged deforming teeth, and one is sandwiched in the middle of the optical fiber microbending deformers 12. The signal optical fiber 13 and a bimetallic sheet 11 composed of two layers of metals (or alloys) with different thermal expansion coefficients, the bimetallic sheet 11 is in contact with the optical fiber microbend deformer 12 .

[0020] The bimetallic sheet 11 is used as a temperature measuring element, which includes two layers of metals or alloys with different thermal expansion coefficients.

[0021] When the temperature changes, the bimetal 11 senses the temperature change, and pushes the optical fiber microbending deformer 12 to generate displacement to change the bending degree of the signal fiber 13 , thereby realizing the modulation of the light intensity in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com