Optical fiber sensor network for multicomponent gases

An optical fiber sensing, multi-component technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of unfavorable site simplification, scale, increase the difficulty of input cost management, and difficult sensing and detection operations, etc. Easy to implement, simplified complexity, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

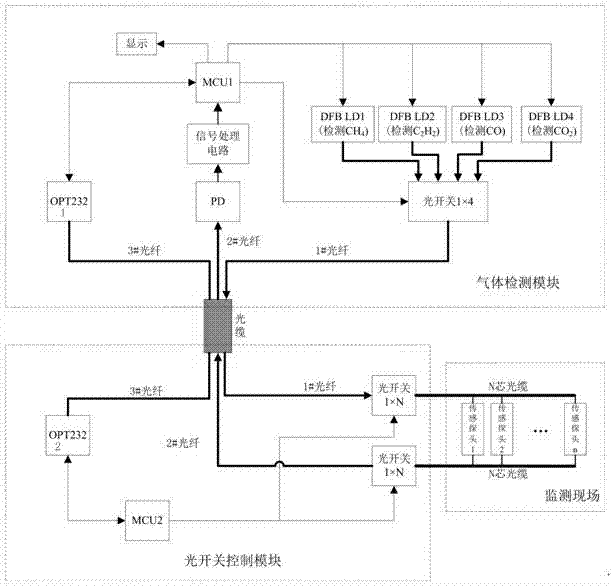

[0017] Such as figure 1 As shown, the multi-component gas optical fiber sensing network consists of three parts: gas detection module, optical switch control module and sensing probe network. The gas detection module can be placed in the monitoring center, away from the monitoring site, where the DFB laser emits laser light corresponding to the absorption wavelength of the corresponding gas to the sensor probe, and performs photoelectric conversion, signal processing and display on the collected optical signal, and the microprocessor 1 Control and integrate the operation of the entire system. The optical switch control module can be placed in a safe area close to the monitoring site, which mainly includes: microprocessor 2 communicates with microprocessor 1 through RS232 to optical fiber device 2 (OPT232-2), and controls two 1×N optical swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com