Novel highly germanium-doped -type light-sensitive optical fibre and method for making same

An optical fiber, highly doped technology, applied in the direction of cladding fiber, optical waveguide light guide, glass manufacturing equipment, etc., can solve the influence of fiber grating sensor network signal, increase the core refractive index of the fiber, reduce the fiber mode field diameter, etc. problem, to achieve the effect of excellent sensing elements, avoid excessive attenuation, and avoid high attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

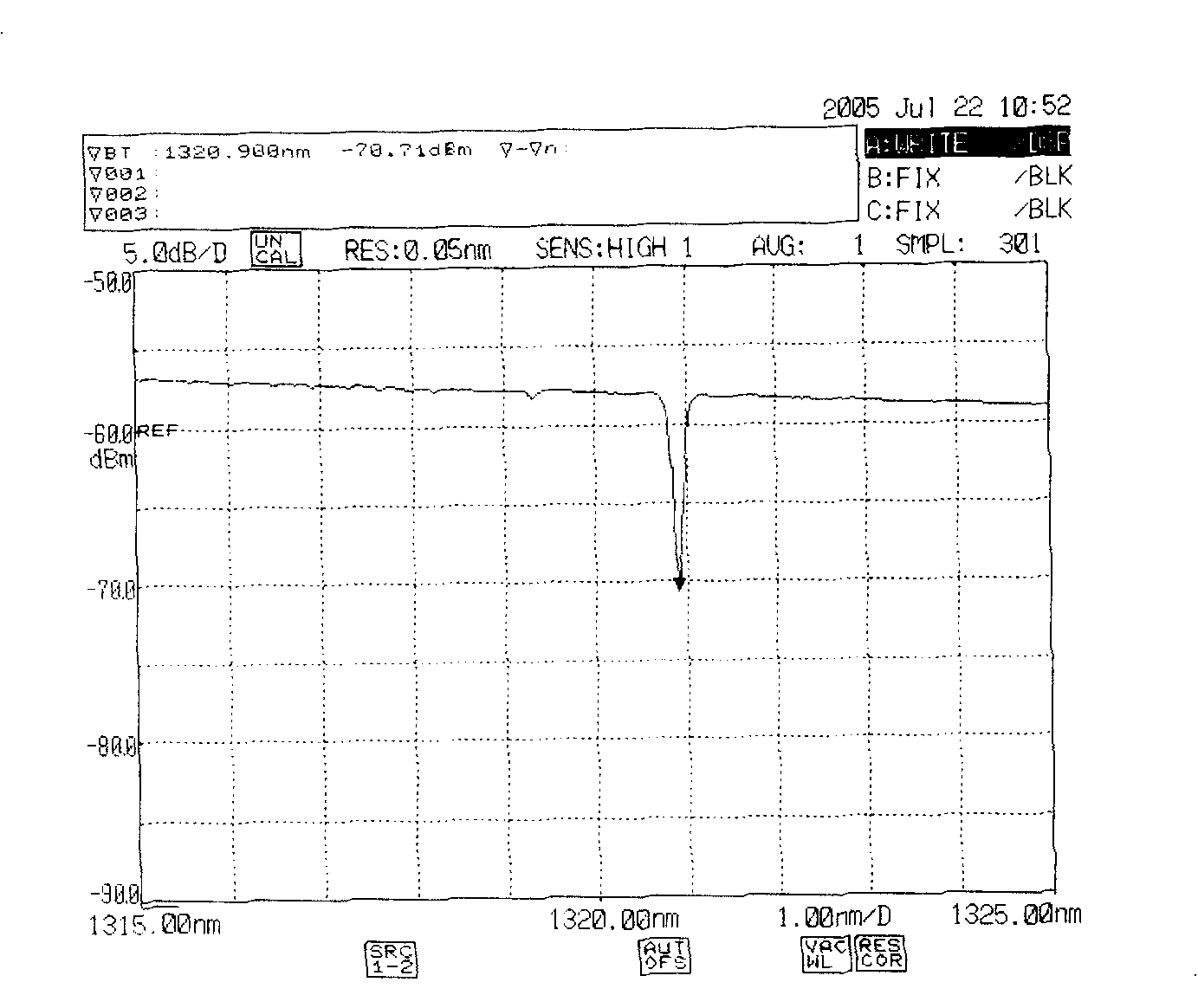

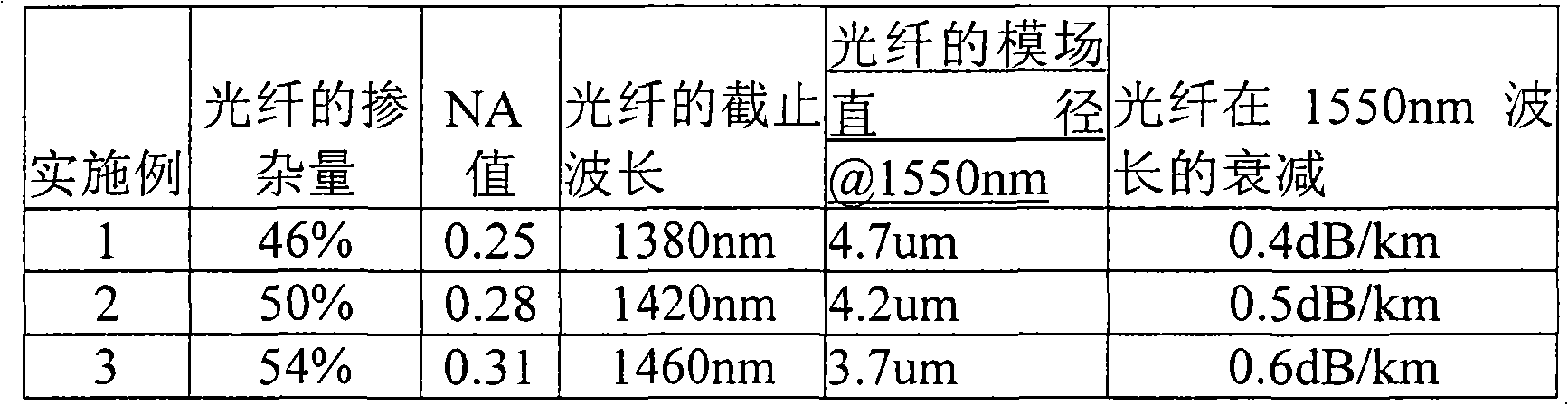

[0036] Example 1: (0.25)

[0037] In this example, using figure 1 The refractive index profile of the high-doped germanium-doped photosensitive fiber is used to set the PCVD process of the optical fiber. First, the cladding is deposited, and then the core is deposited; the core is inserted into the cladding for melting and shrinking to obtain a preform; The preform is drawn to obtain an optical fiber; the core layer is doped with 46% germanium element, and the germanium element is doped by adding germanium tetrachloride and oxygen to the core layer of the optical fiber to react; during the deposition process of the core layer Passed a lot of O 2 , and control the oxygen-silicon ratio to 3.0; the deposition rate of the core layer is 0.5g / min; in the process of melting and shrinking, control the shrinkage aperture to 2mm; when drawing, control the drawing temperature to 2000°C, and finally obtain a photosensitive optical fiber with a cut-off The wavelength is in the range of 1...

Embodiment 2

[0038] Example 2: (0.28)

[0039] In this example, using figure 1 The refractive index profile of the high-doped germanium-doped photosensitive fiber is used to set the PCVD process of the optical fiber. First, the cladding is deposited, and then the core is deposited; the core is inserted into the cladding for melting and shrinking to obtain a preform; The preform is drawn to obtain an optical fiber; the core layer is doped with 50% germanium element, and the germanium element is doped by adding germanium tetrachloride and oxygen to the core layer of the optical fiber for reaction; during the deposition process of the core layer Passed a lot of O 2 , and control the oxygen-silicon ratio to 4.5; the deposition rate of the core layer is 1g / min; during the melting and shrinking process, control the shrinkage aperture to 7mm; when drawing, control the drawing temperature to 2100°C, and finally obtain a photosensitive optical fiber. The doping of germanium leads to the increase ...

Embodiment 3

[0040] Example 3: (0.31)

[0041] In this example, using figure 1 The refractive index profile of the high-doped germanium-doped photosensitive fiber is used to set the PCVD process of the optical fiber. First, the cladding is deposited, and then the core is deposited; the core is inserted into the cladding for melting and shrinking to obtain a preform; The preform is drawn to obtain an optical fiber; the core layer is doped with 54% germanium element, and the germanium element is doped by adding germanium tetrachloride and oxygen to the core layer of the optical fiber to react; during the deposition process of the core layer Passed a lot of O 2 , and control the oxygen-silicon ratio to 4.0; the deposition rate of the core layer is 0.8g / min; in the process of melting and shrinking, control the shrinkage aperture to 4mm; when drawing, control the drawing temperature to 2050°C, and finally obtain a photosensitive optical fiber. The doping of germanium leads to the increase of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com