Device for producing a spun-bonded non-woven

A technology for monitoring devices, polymers, applications in measuring devices, textile and paper making, material analysis using acoustic/ultrasonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

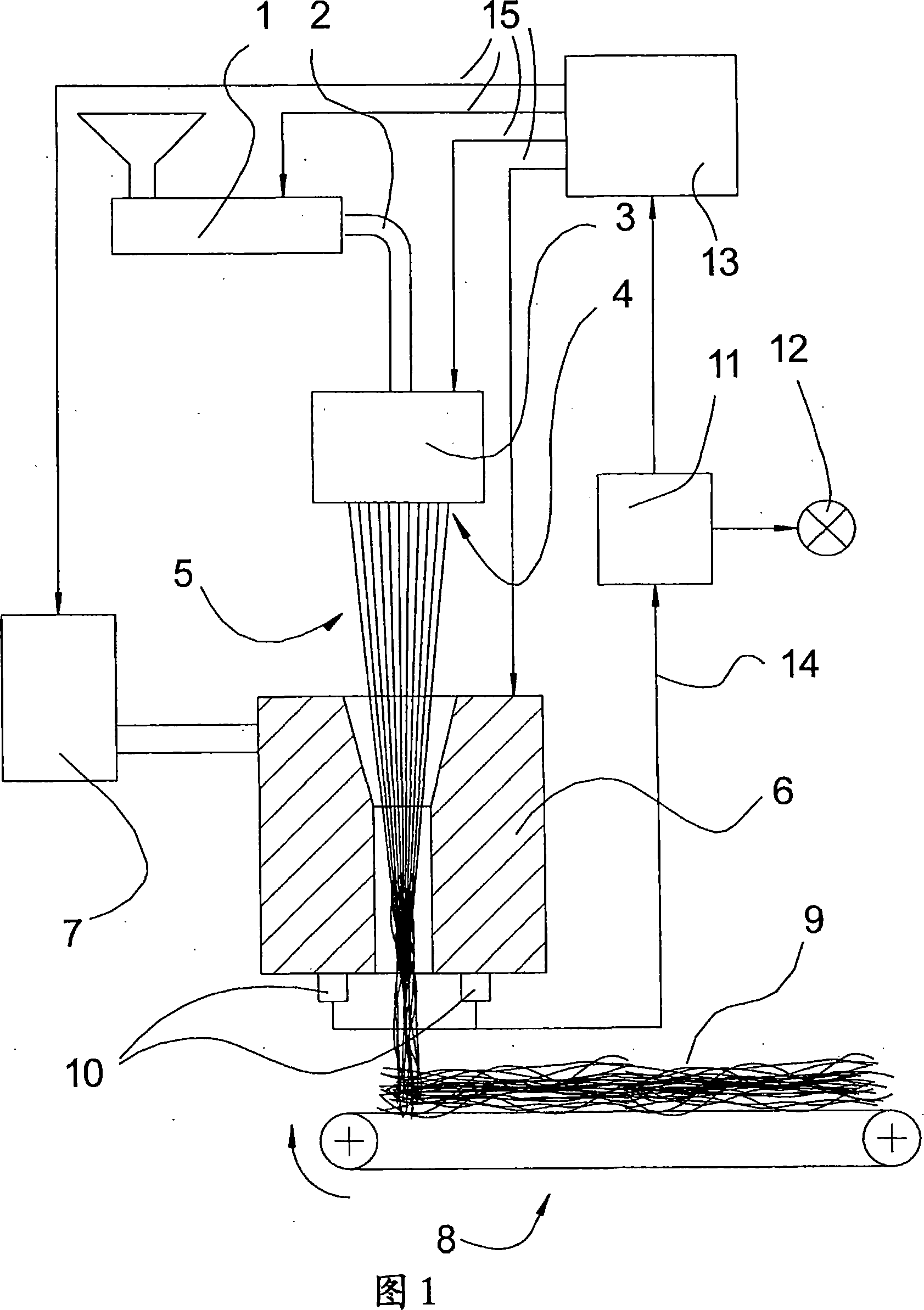

[0026] FIG. 1 shows an apparatus for melt spinning according to the present invention, which is an apparatus for producing spunbond nonwoven fabrics in this embodiment. From a melt source 1 , for example an extruder, the polymer in molten state is fed to a spin beam 3 via a melt line 2 . The spin beam 3 extends perpendicular to the plane of the drawing over a width approximately corresponding to the width of the spunbond nonwoven to be produced. On its underside, the spin beam 3 has a plurality of spinneret holes 4 through which the molten polymer is fed under high pressure and formed into filaments 5 . The internal structure of the spinning beam 3 with distribution lines, a spinning pump for increasing the pressure and a heating device is known from the prior art.

[0027] The monofilaments 5 emerging from the spinning beam 3 are arranged perpendicular to the plane of the drawing in the shape of a curtain and are fed to a drawing nozzle 6 . The draw-off nozzle 6 also extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com