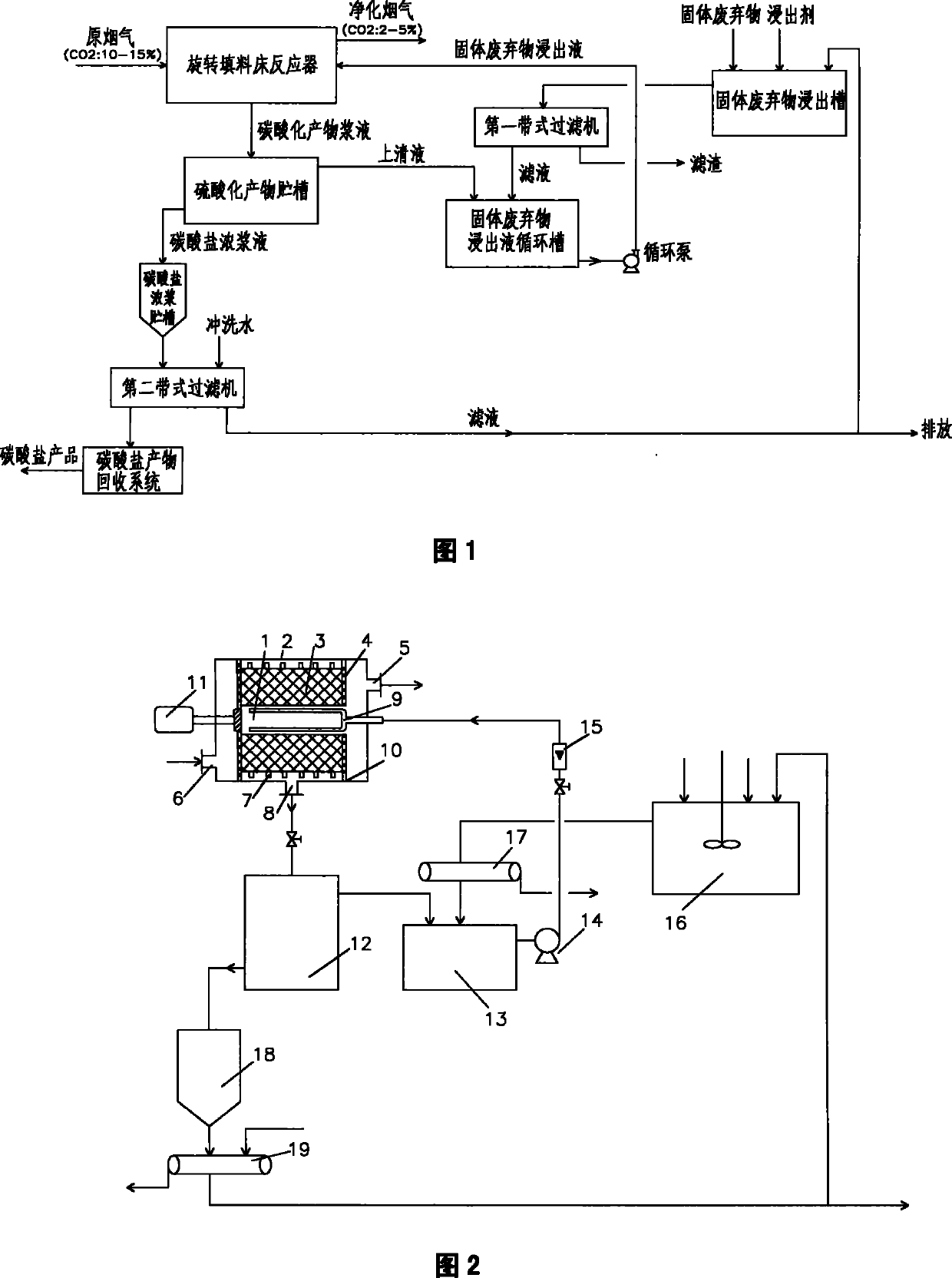

Method and device for fixing CO2 in stack gas by solid castoff carbonatation

A solid waste, carbonation technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of application limitation and high cost, and achieve the improvement of reaction rate, mass transfer and absorption rate, and carbon fixation. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

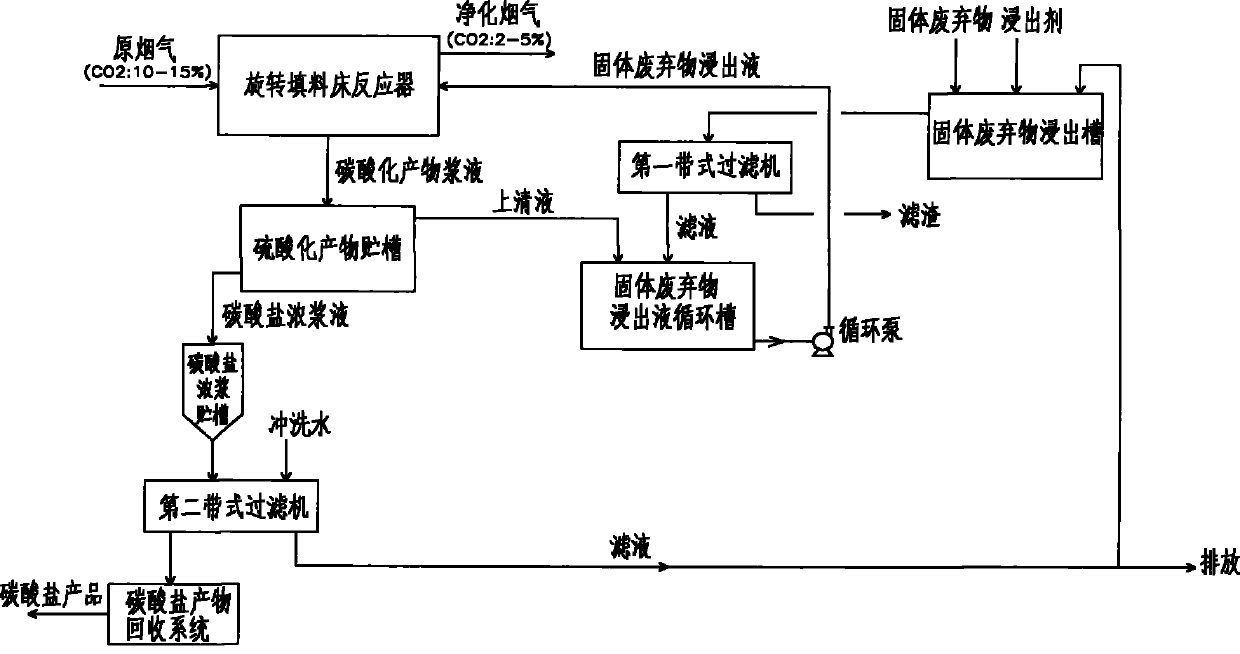

Embodiment 1

[0020] Put the steel slag and the gray water from the power plant into the solid waste leaching tank 16 according to the gray-water ratio of 1:10, stir and leach for 1 hour, and filter to obtain Ca-enriched 2+ Leachate, Ca 2+ The concentration is 0.2mol / L; the prepared Ca-rich 2+ After the leaching solution is measured by the circulating pump 14 and the flow meter 15, it is sprayed into the metal mesh packing layer 3 loaded with carbonic anhydrase by the liquid distributor 9, containing 12% CO 2 The simulated flue gas enters the rotating packed bed reactor 1 through the inlet 6, and is enriched with Ca 2+ The leaching solution cross-flow contacts in the rotating packed bed reactor and undergoes carbonation reaction, and the carbonate product after the reaction enters the CaCO 3 Recovery system, CO removal 2 The final simulated flue gas leaves the rotating packed bed reactor 1 through the exhaust port 5 .

[0021] The rotor speed of the rotating packed bed is 1200rpm, the c...

Embodiment 2

[0024] The solid waste used in the experiment is high-calcium fly ash, and all the other are the same as in Example 1; CO 2 The removal rate is 57%, Ca2 + The conversion rate is 64%, and the obtained carbonate product is analyzed by XRD, and the main component is CaCO 3 , accounting for more than 90%.

Embodiment 3

[0026] Ca-enriched 2+ , Mg 2+ The natural salt water of the leaching agent is made, and all the other are the same as embodiment 1; CO 2 The removal rate is 69%, Ca2 + The conversion rate is 58%, and the obtained carbonate product is mainly CaCO through XRD analysis 3 and a small amount of MgCO 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com