Horizontal continuous unmuffled light annealing equipment of stainless steel band

A stainless steel strip and annealing equipment technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as crashing electric heating elements, increasing equipment costs and maintenance costs, and affecting the normal annealing production process, so as to avoid longitudinal middle sagging , increasing the effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

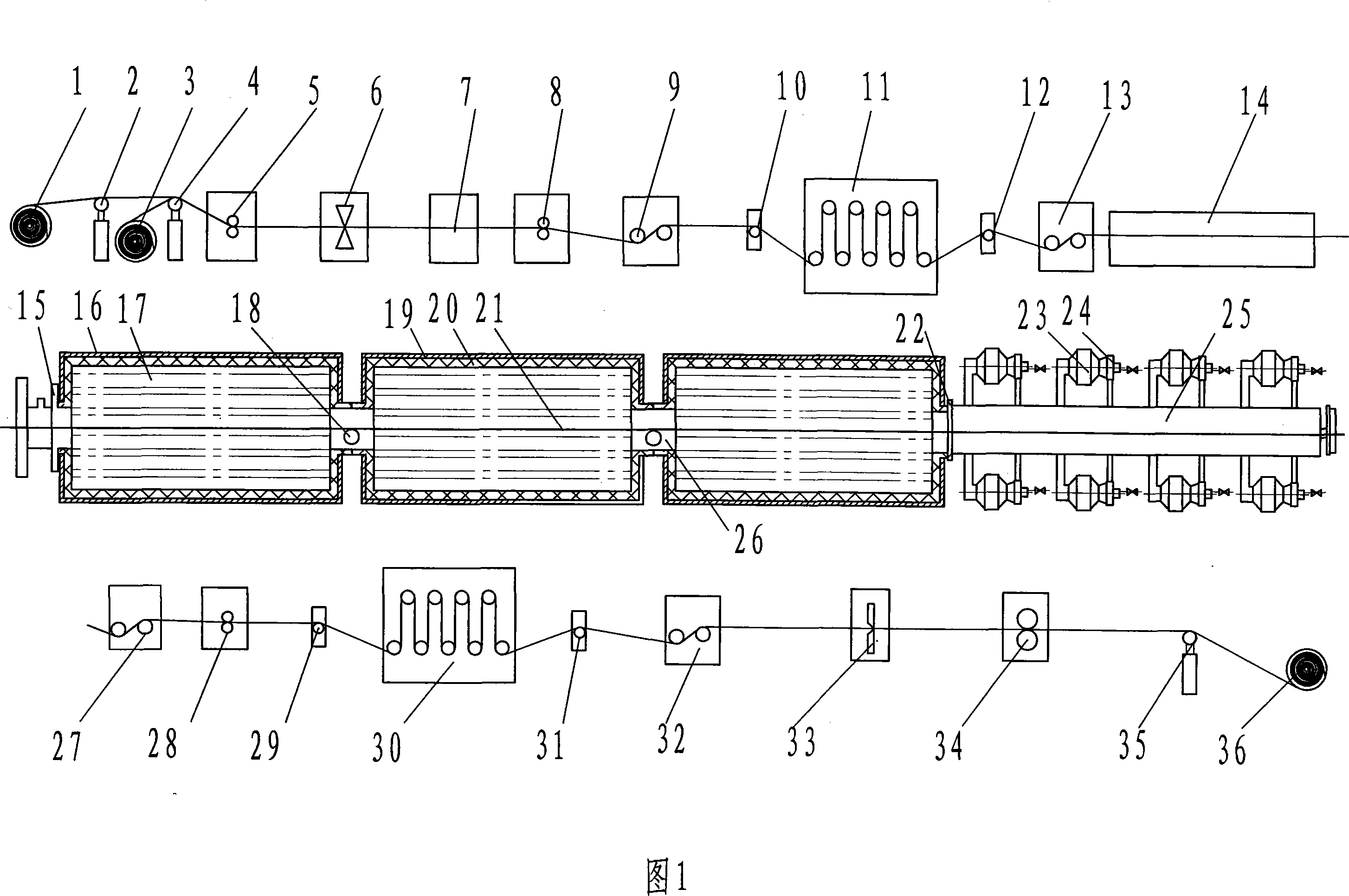

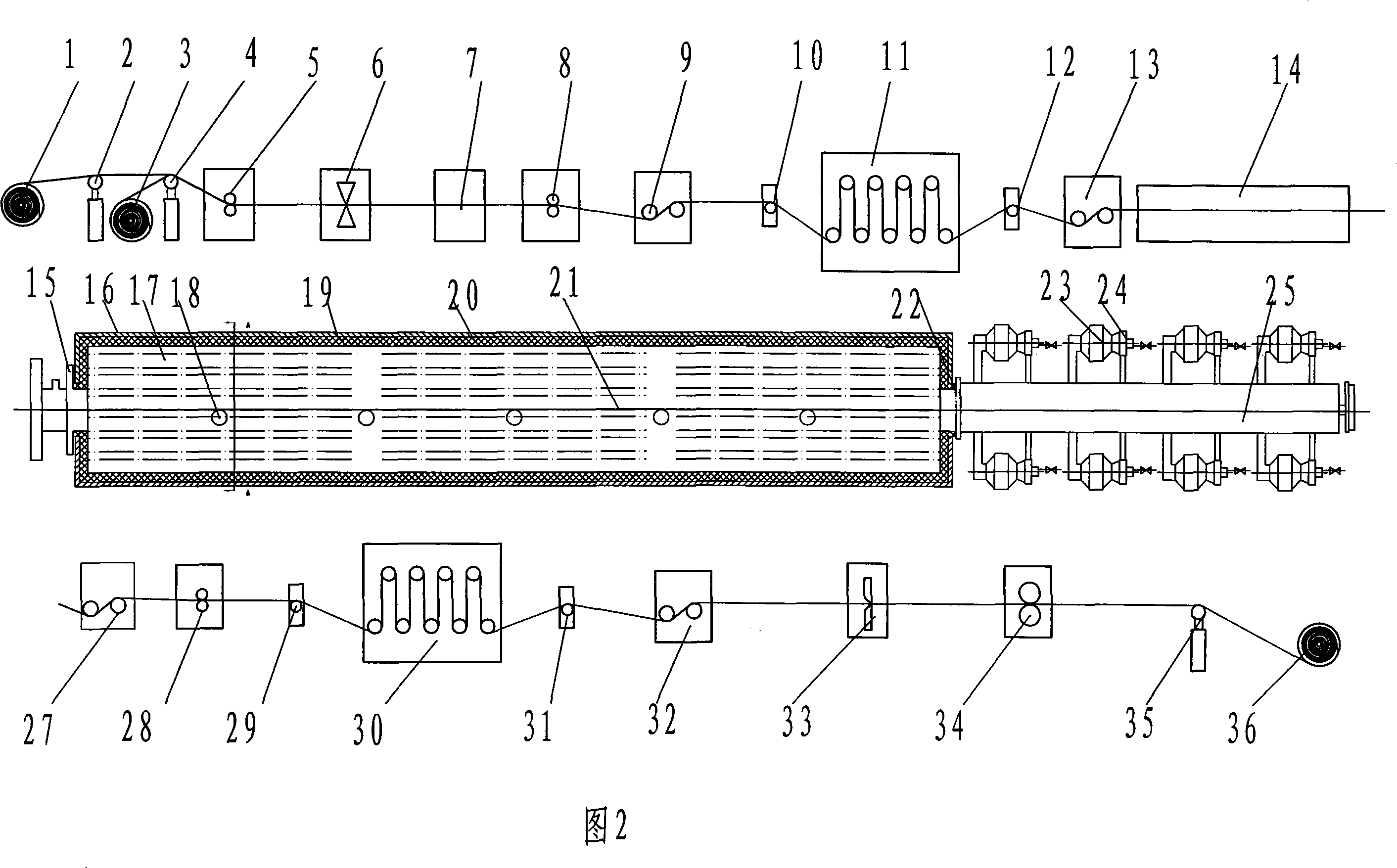

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

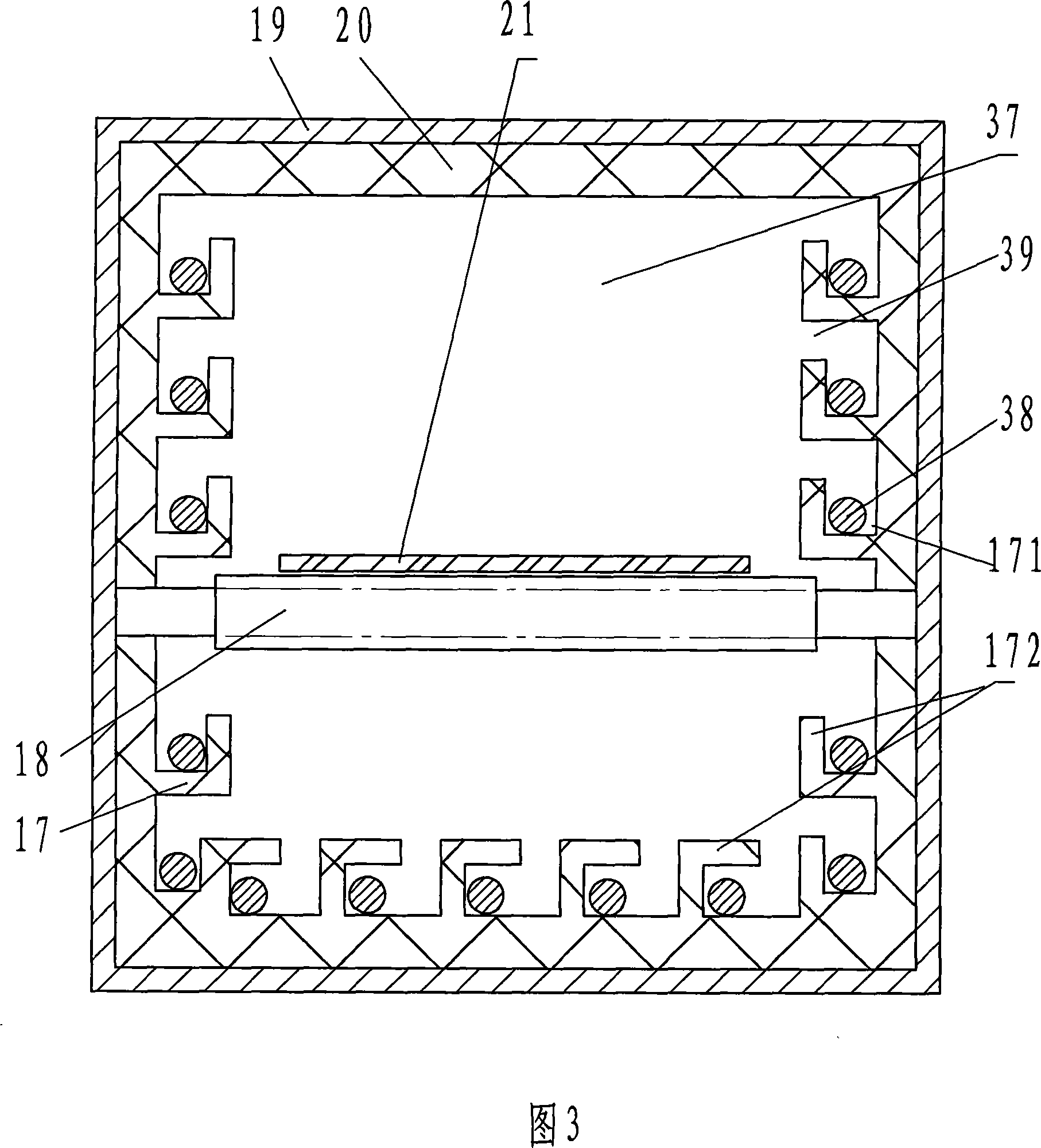

[0023] As shown in Fig. 1, Fig. 2 and Fig. 3, the stainless steel belt horizontal continuous muffle-free bright annealing equipment of the present invention includes a horizontal muffle-free annealing furnace 16, a cooling device and a transmission system.

[0024] The horizontal muffle-free annealing furnace 16 includes a steel structure 19 of the furnace body, that is, an outer shell, a thermal insulation layer 20 placed on the inner wall of the steel structure 19 of the furnace body, an electric heating body 38 arranged in the furnace hearth 37, and placed in the furnace body 37 to enter Furnace inlet seal 15 at the outlet end, furnace outlet seal 22 and connecting flange (not marked in the figure) etc.

[0025] The cooling device includes a heat exchanger 23 connected to each other, a cooling fan 24, a protective gas inlet valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com