Large, middle span width roof hollow thermal insulation, heat insulation structure and construction method thereof

An empty-bellied structure, an empty-bellied technology, which is applied in thermal insulation, roofing, building roofs, etc., can solve the problems of increasing the load of the structural layer, the limited use of the roof, and the destruction of prefabricated panels, and achieves the effect of increasing stiffness and bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

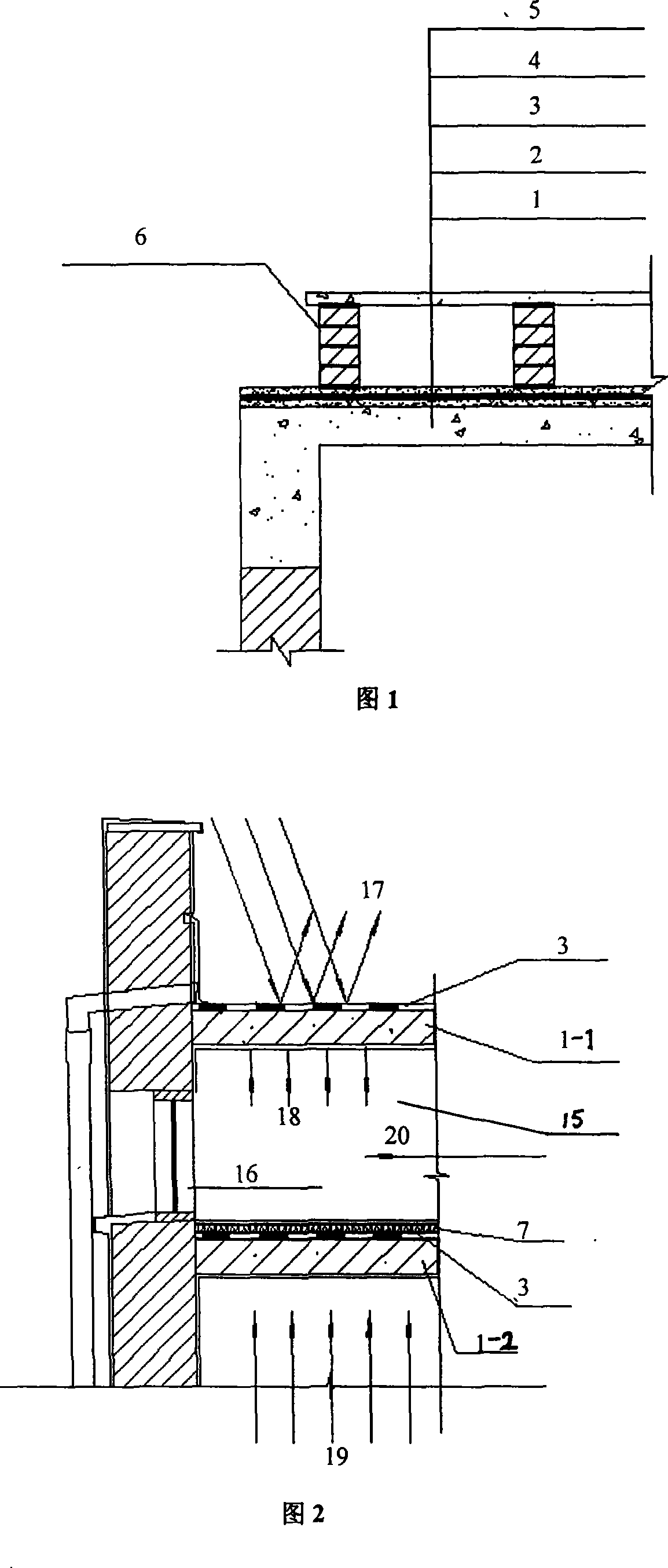

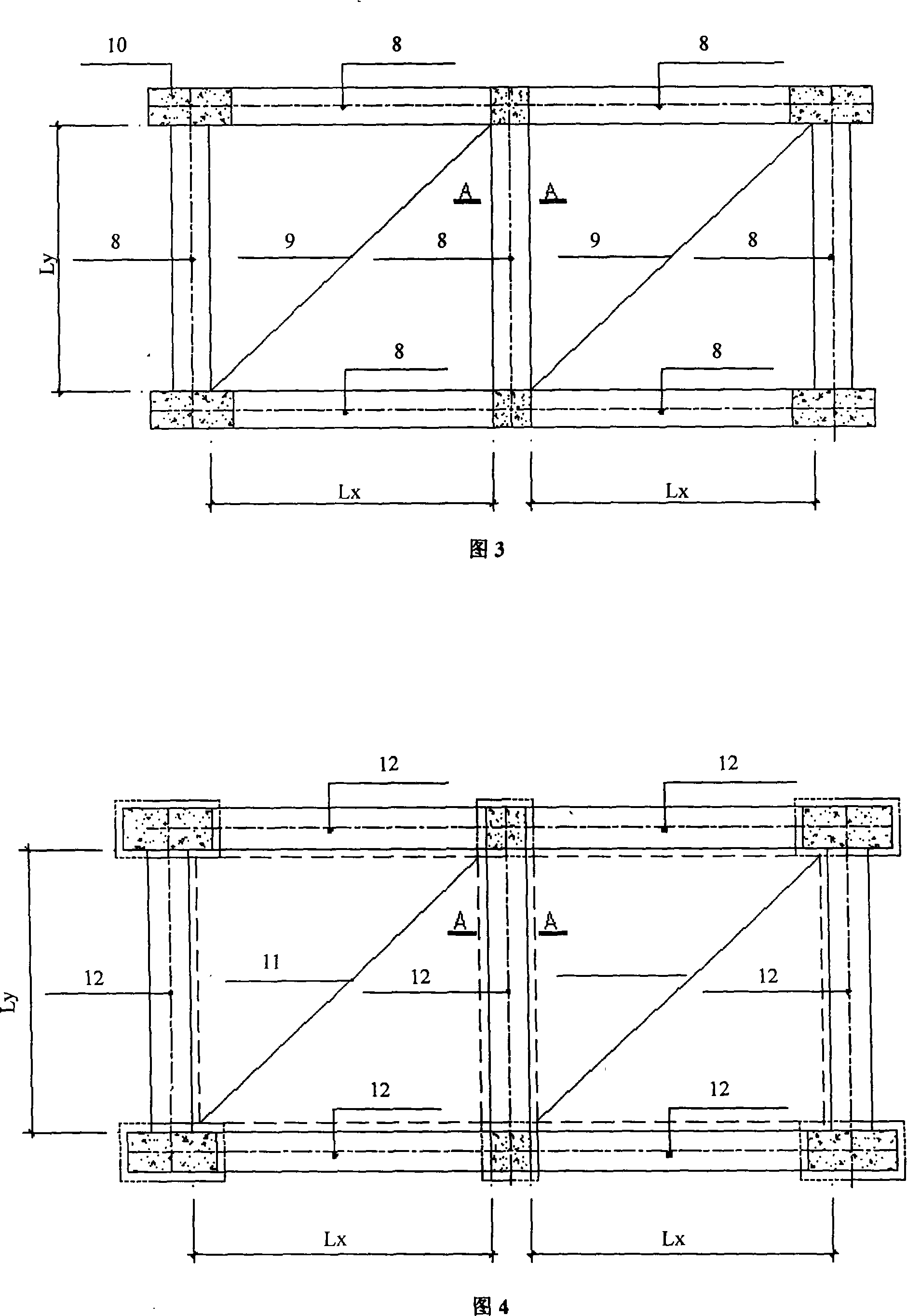

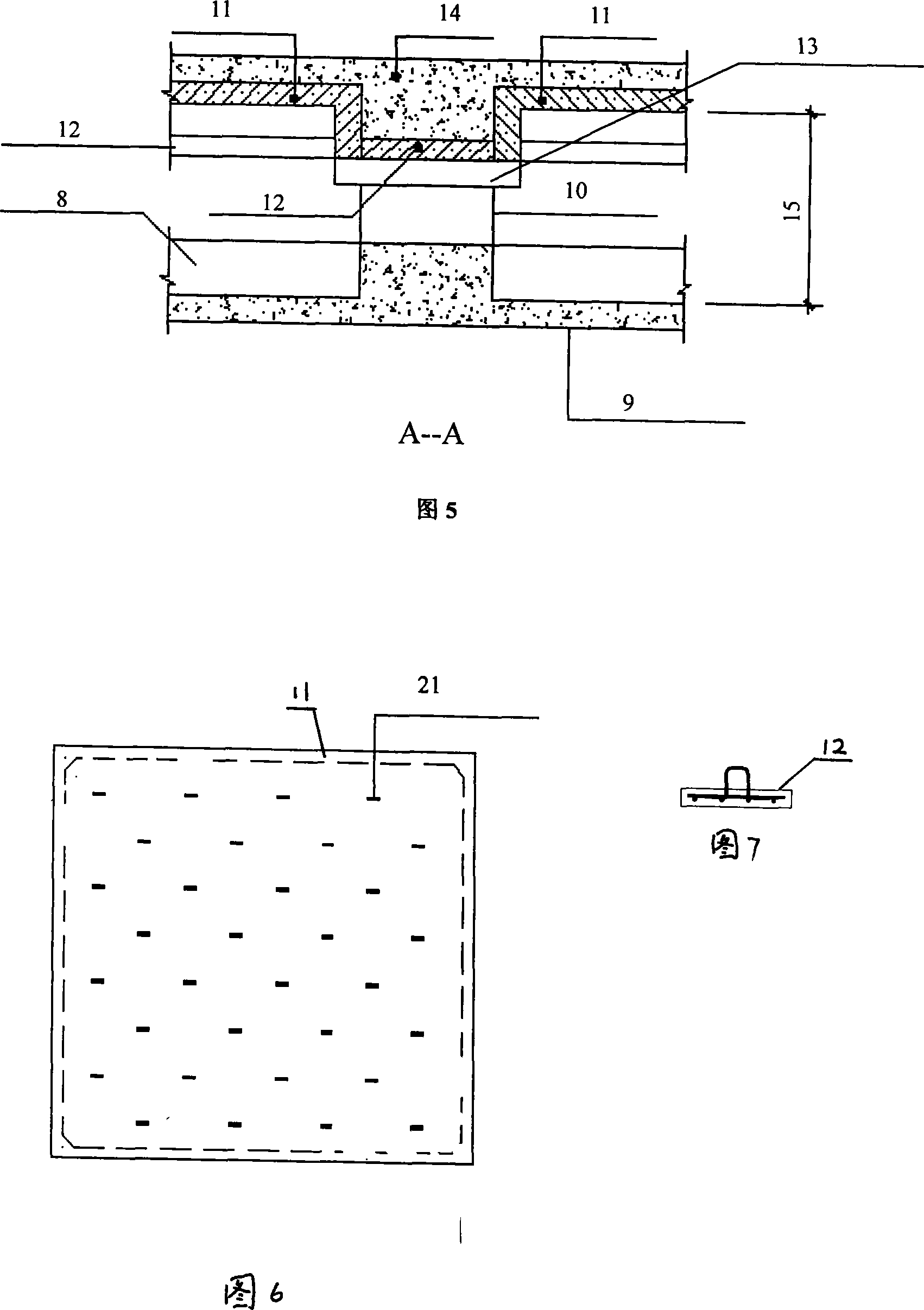

[0022] As shown in Figure 2, a kind of large, mid-span roof fasting thermal insulation and heat insulation structure provided by the present embodiment comprises an upper structural layer 1-1 and a lower structural layer 1-2, as shown in Figure 4, the described The upper structural layer 1-1 is an upper chord rib layer composed of the first prefabricated slab 11 as the upper chord rib and the second prefabricated slab 12 as the upper chord slab, as shown in Figure 3, the lower structural layer 1-2 is composed of the lower chord rib 8 and the lower chord plate 9 composed of the lower chord rib layer, the upper chord rib layer and the lower chord rib layer are connected by the shear key 10 to form a hollow structure. From the analysis of structural mechanical properties, the overall bending moment of the hollow structure is transformed into the compressive and tensile axial forces of the upper chord ribs, upper chord plates, lower chord ribs, and lower chord plates, and the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com