Air hydrostatic bearing of machine making free piston type reciprocating motion

A reciprocating motion, gas static pressure technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of increased gas consumption of gas static pressure bearings and reduced mechanical efficiency of free-piston reciprocating motion, so as to improve efficiency and load bearing capacity. The effect of improving capacity and rigidity and reducing air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

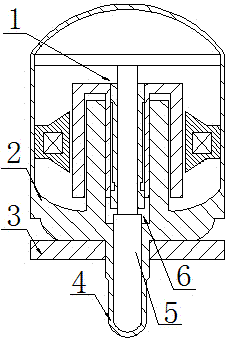

[0020] The present invention is applicable to various free-piston reciprocating machines. The present invention will be further described by taking the free-piston Stirling refrigerator as an example and in conjunction with the accompanying drawings:

[0021] Such as figure 1 As shown, the piston 1 is installed in the cylinder 2, and the linear motor drives the piston to reciprocate along the cylinder wall. According to the thermodynamic cycle law, when the refrigerator is in motion, the gas at the cold end 4 passes through the regenerator, and heat is pumped to the hot end 3 . In this way, the refrigerator achieves the cooling effect and meets the cooling requirements of mechanical parts and electronic devices that require deep cooling.

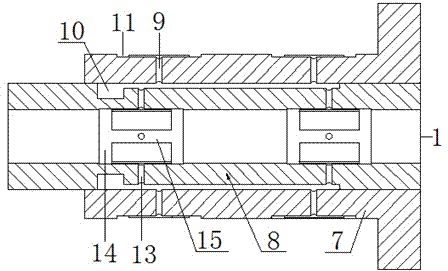

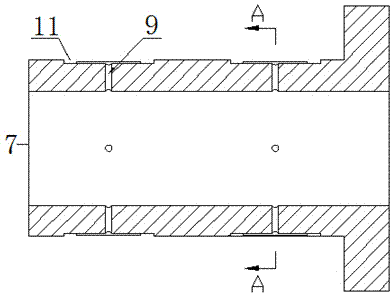

[0022] Such as figure 1 and figure 2 The shown aerostatic bearing for a free-piston reciprocating machine includes a piston 1 , a cylinder 2 , an ejector 5 , a compression chamber 6 and an air storage tank 10 . The piston 1 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com