Exterior lifting and pressing type ream bit for solum hole

A technology for reaming drill bits and soil layers, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc. It can solve the problems of high failure rate, complicated drill mechanism, and high cost, and achieve low failure rate, few drill expansion mechanisms, and simple form Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

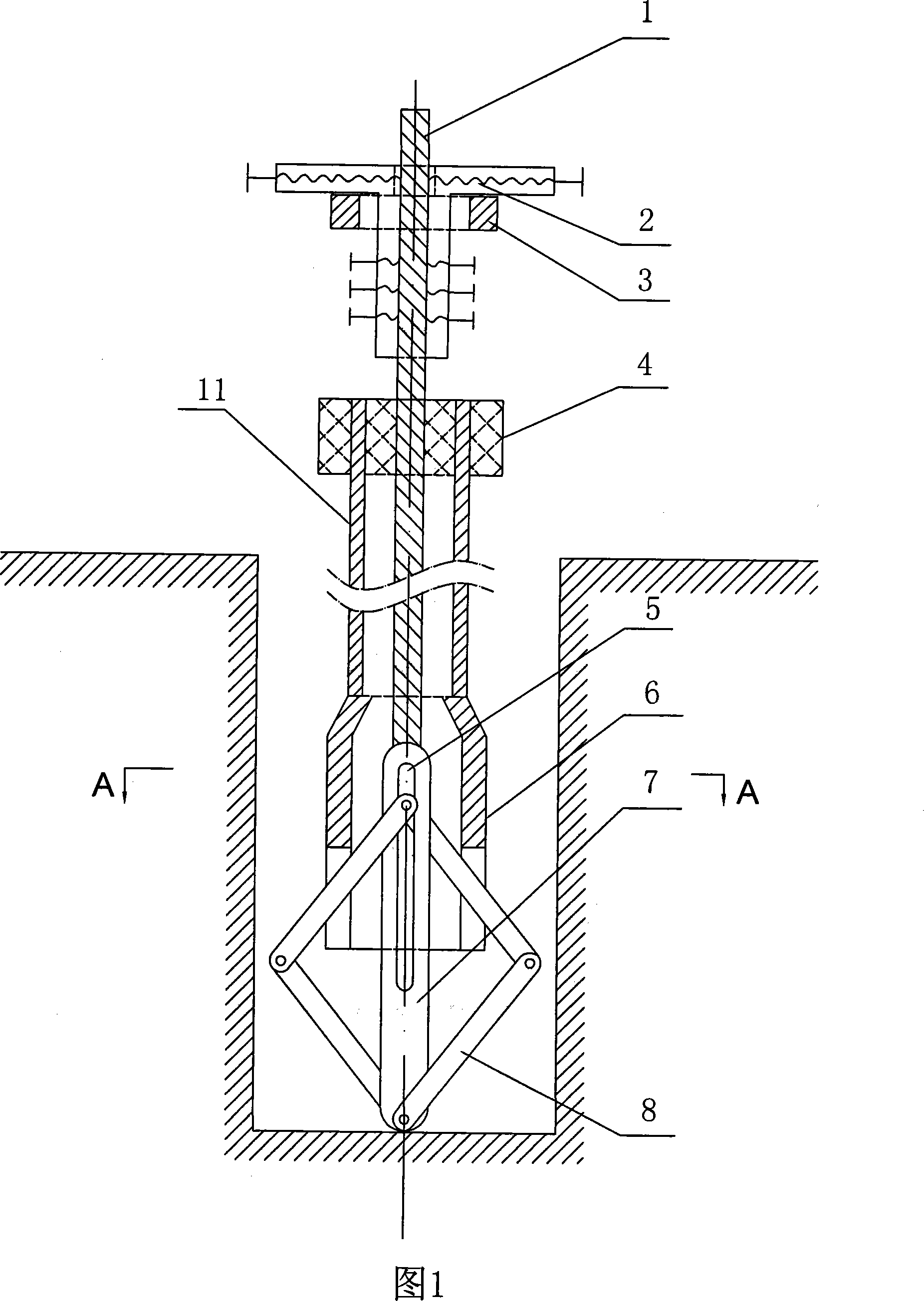

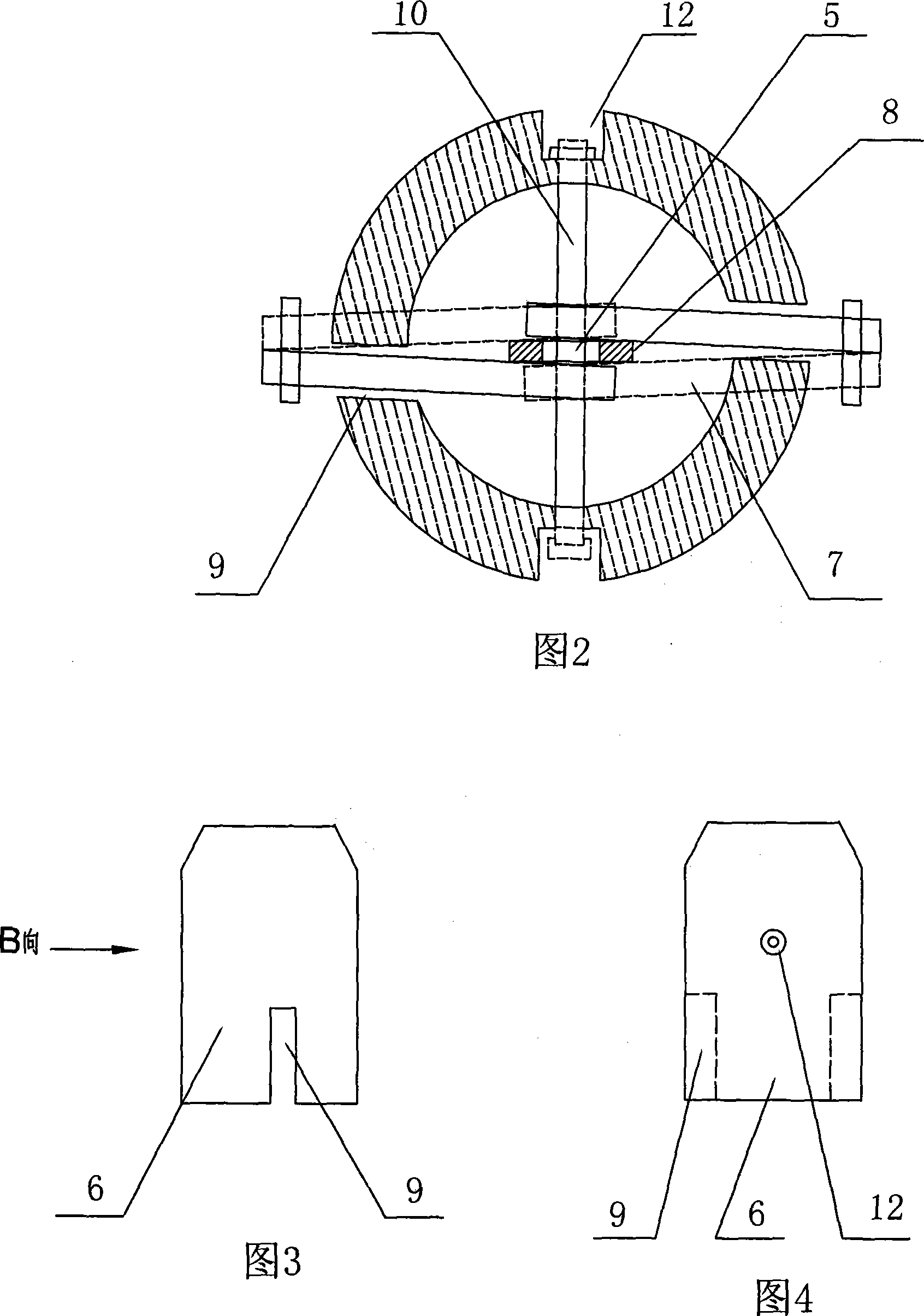

[0024] Embodiment 1: Referring to FIG. 1 to FIG. 4 , a lifting and pressing type reaming drill bit outside a soil layer hole includes a drill power head 4 , a drill pipe 11 , a drill body and a tie rod 1 . Said drill head 4 is connected with the drill rod 11, the drill rod 11 is connected with the drill bit body 6, and the tie rod 1 movably penetrates the drill rod 11 and the drill bit body. The upper part of the pull rod 1 is provided with a rotating bracket, which includes a pressure bearing 3 and a pull rod clamp 2 arranged on the pressure bearing 3, the pull rod 1 is fixed in the pull rod clamp 2 and is located at the center of the pressure bearing 3 . Said pull rod clamping part 2 is a "T" type casing, and jackscrews for fixing the pull rod 1 are provided on the wall of the vertical tube and at both ends of the horizontal tube. The pressure bearing 3 in the rotating support is fixedly arranged on the external support.

[0025] Said drill bit body comprises drill bit bod...

Embodiment 2

[0026] Embodiment 2: Referring to Fig. 1 to Fig. 4, the present invention can be implemented with the help of existing drilling equipment.

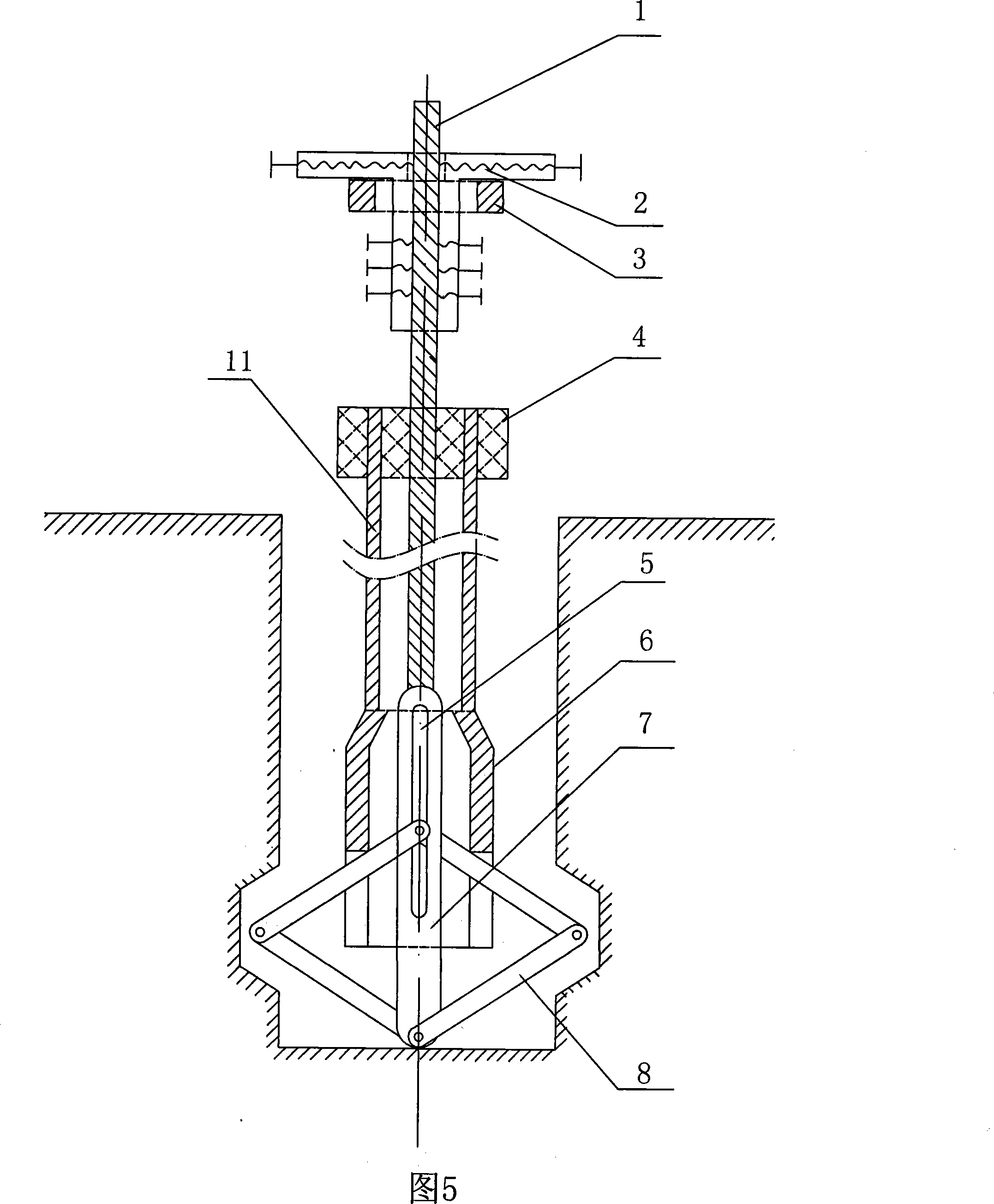

[0027] Place the expansion fins of the planar four-bar linkage mechanism 8 in the expansion notch 9 on the drill body 6, and connect its upper contact and sliding piece 7 to the lower push rod 10. When connecting, the lower push rod 10 passes through the upper contact and the sliding piece. The diffuser groove 5 of the sheet 7 is vertical to the plane controlled by the expansion notch 9 and fixed on the drill body 6; the expansion fins and the reaming fins are connected, and the lower contact of the reaming fins is connected to the sliding plate 7. on the lower endpoint. Connect the sliding plate 7 and the pull rod 1, the drill body 6 is connected to the bottom of the drill rod 11, and the pull rod 1 passes through the center of the drill rod 11 and passes through the upper end hole of the drill rod.

[0028] The upper end of the drill p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap