Damper of vehicle damping mechanism

A technology of automobile shock absorption and damper, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., to achieve the effect of reducing discomfort, convenient use and operation, and alleviating the problem of excessive acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

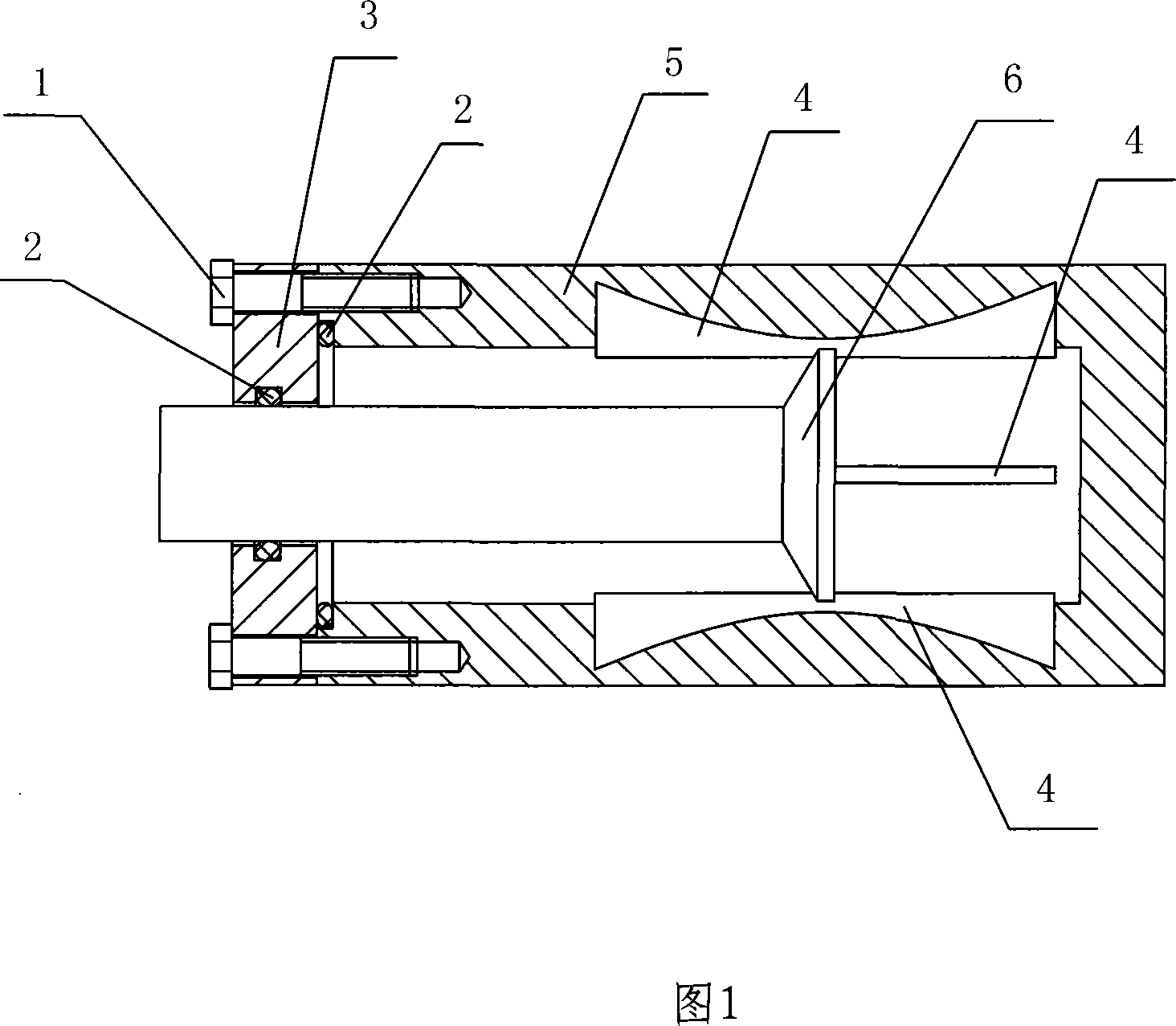

[0017] As shown in Figure 1, the damper of the automobile shock absorbing mechanism has a bottom cylindrical cylinder body and a piston 6 accommodated in the cylinder body in a coaxial free reciprocating manner, and its bottom cylindrical cylinder body is formed by the damper body. 5 and the top cover 3, the piston 6 is composed of a piston rod penetrating the top cover 3 and a bottom part used in conjunction with the damper body 5. Simultaneously, the inner wall of the damper body 5 is evenly and symmetrically formed along the axial direction with four symmetrical curved grooves 4 with both ends of the middle protrusion depressed. Wherein the curve equation of the curve groove 4 is y=a|x 3 |, where -1<a<1 and when the number of curved grooves 4 is greater or the inflation pressure in the damper body 5 is greater, the coefficient a is greater. The top cover 3 is fixedly mounted on the damper body 5 through a plurality of bolts 1 evenly and symmetrically distributed thereon. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com