Method for improving service lifetime of concrete delivery pump pipe and its pump pipe

A technology for concrete delivery pumps and pump pipes, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline damage/wear prevention, etc., can solve wear resistance and manufacturing cost dissatisfaction, manufacturing cost and structural weight increase, structural Weight reduction and other issues, to achieve the effect of reducing thickness and structural weight, manufacturing cost and structural weight, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

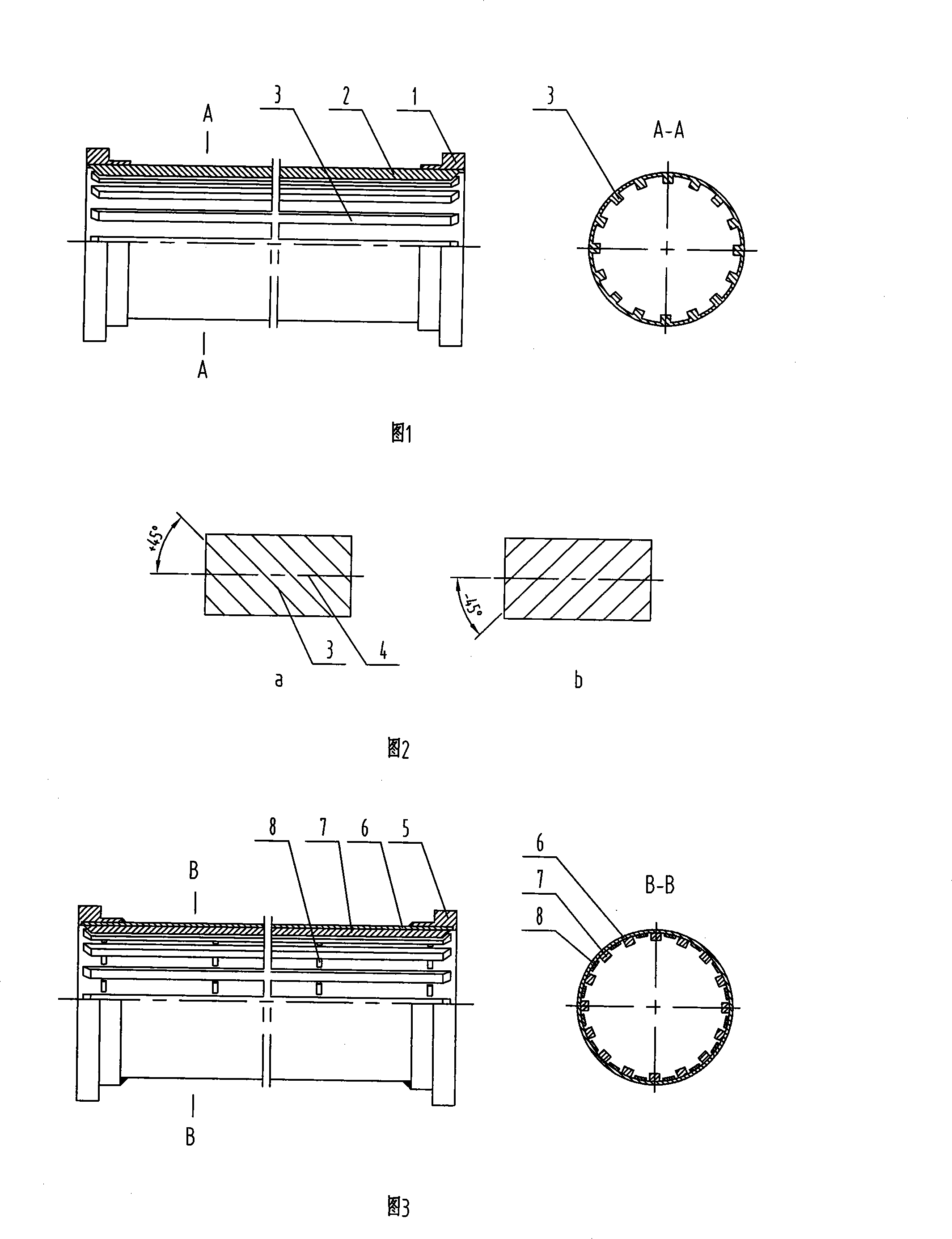

[0023] The implementation method of the present invention is as follows: the pump tube includes the pump tube flange 1 and the pump tube body 2, by setting at least one longitudinal protrusion 3 on the inner wall of the pump tube body 2, and adjusting the alignment between the protrusion 3 and the pump tube axis 4 The included angle on the projection surface makes the concrete mainly produce friction with the protrusion 3 when it moves in the pipe and less or no friction with the inner wall of the pump pipe body 2, thereby improving the service life of the pump pipe and reducing the structural weight. The included angle between the protrusion 3 and the pump tube axis 4 on the projection plane is between +45° and -45°, as shown in Fig. 1 and Fig. 2a and Fig. 2b.

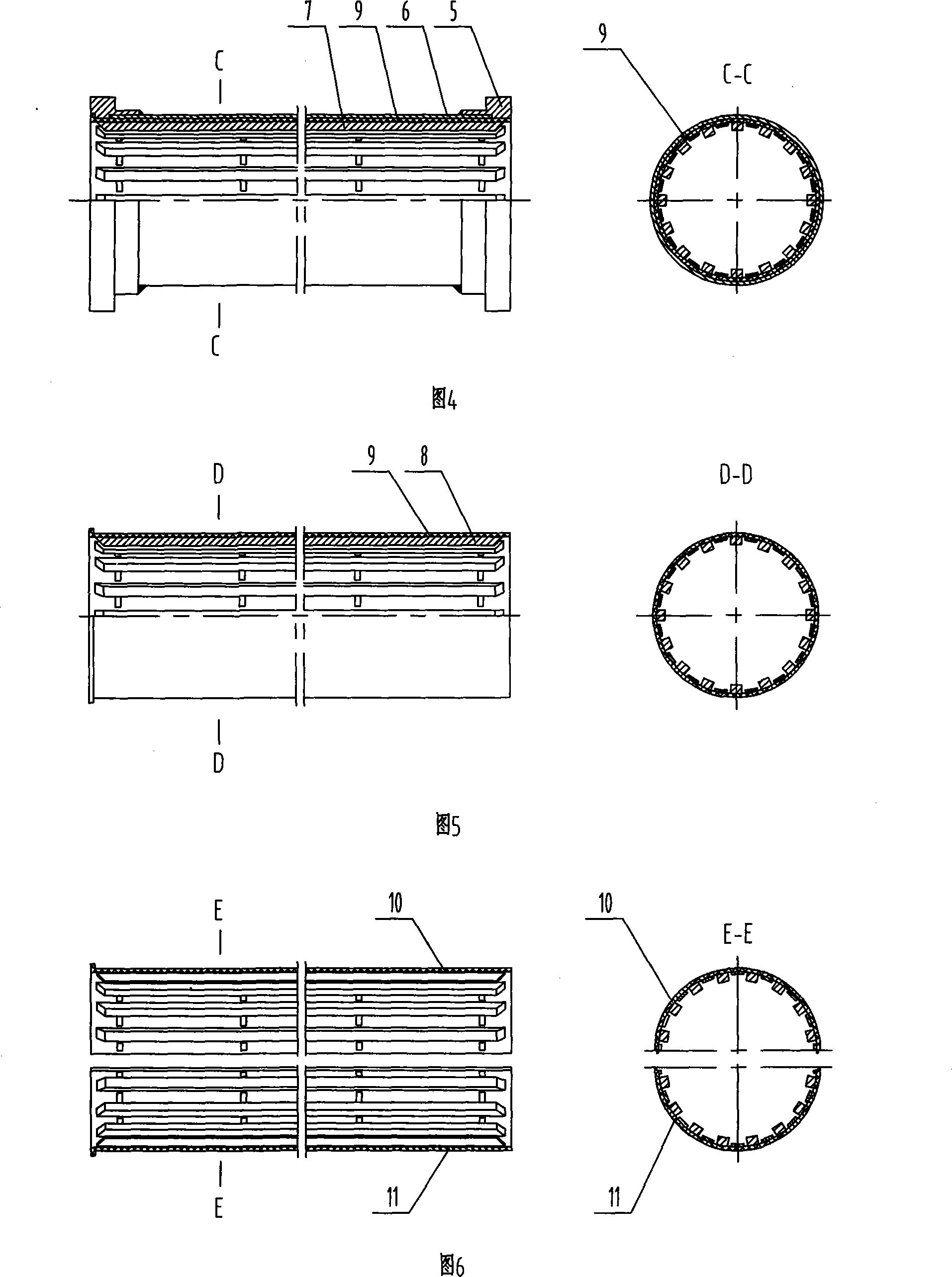

[0024] In one embodiment of the present invention, the pump tube manufactured by the above method includes a flange 5 and a tube body 6, and at least one guide bar 7 is arranged on the inner wall of the tube body 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com