Flavoured skewer

A technology for skewering meat and skewers, which is applied in the field of skewers and can solve problems such as unsuitable adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Encapsulation of spices

[0054] Commercially available flavor solutions were encapsulated in microorganisms according to the following procedure:

[0055] 100 g of spray-dried yeast (DHW in Germany) were dispersed in 375 g of water. 75 g of lemon flavor composition (available from Firmenich SA, Switzerland) were added and stirred continuously at 150 rpm in a paddle stirrer at 50° C. for 4 hours.

[0056] Then, 150 g of maltodextrin (DE 18) were added and stirred until the whole aqueous mixture became homogeneous.

[0057] The mixture was then spray dried with a Niro mobile minor(R) at an inlet temperature of 210°C and an outlet temperature of 90°C at a feed rate of 10 ml / min. A powder of microcapsules based on microorganisms, matrix components and at least one fragrance is obtained. The resulting flavor capsules contained 40% by weight yeast, 40% by weight maltodextrin and 20% by weight liquid flavor.

[0058] Repeat the same steps with the same amount of pepper ...

Embodiment 2

[0060] Preparation of Skewers with Flavor Coating

[0061] The coating is prepared in the form of a viscous edible film.

[0062] Hot water 79.16%

[0063] * Pullulan gum P120 19.80%

[0064] Glycerin 0.99%

[0065] #tween80 0.05%

[0066] * Acquired from Hayashibara Company, LTD

[0067] #polyoxyethylene (20) sorbitan monooleate

[0068] In a clean glass beaker, stir together glycerin and Tween 80. Hot water (80°C) was added to the beaker and mixed thoroughly. Slowly add the pullulan gum to the water and stir until all the pullulan gum is dissolved. A clear and very viscous liquid was obtained.

[0069] The microcapsules obtained in Example 1 were added to the viscous coating as a viscous liquid and 19% by weight of the total weight of the microcapsules.

[0070] Manually spread coating over skewers with fingertips. Once the skewers are evenly coated, leave to air dry for 12 hours or until the adhesive (coating) hardens.

Embodiment 3

[0072] Preparation and sensory analysis of flavored foods

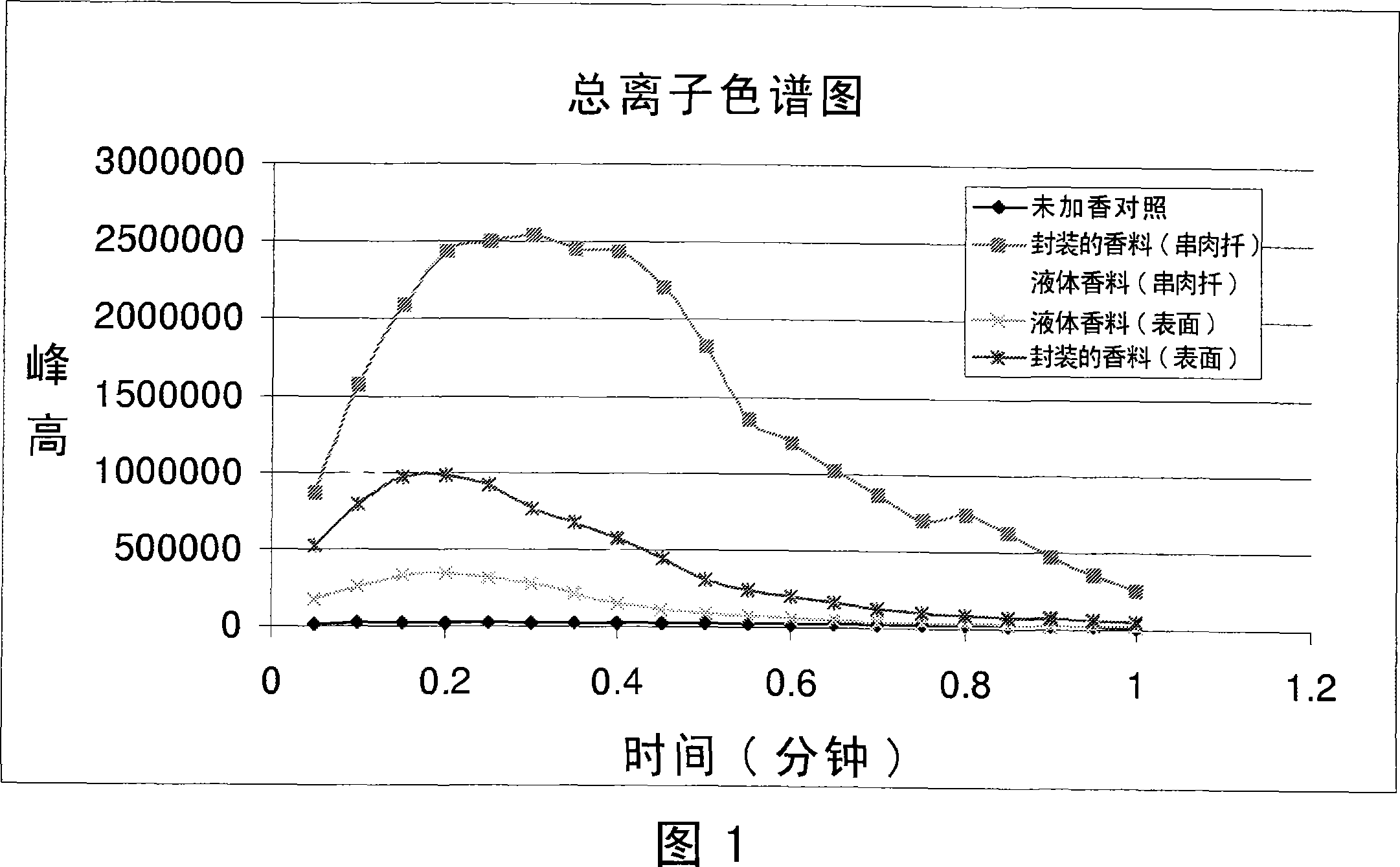

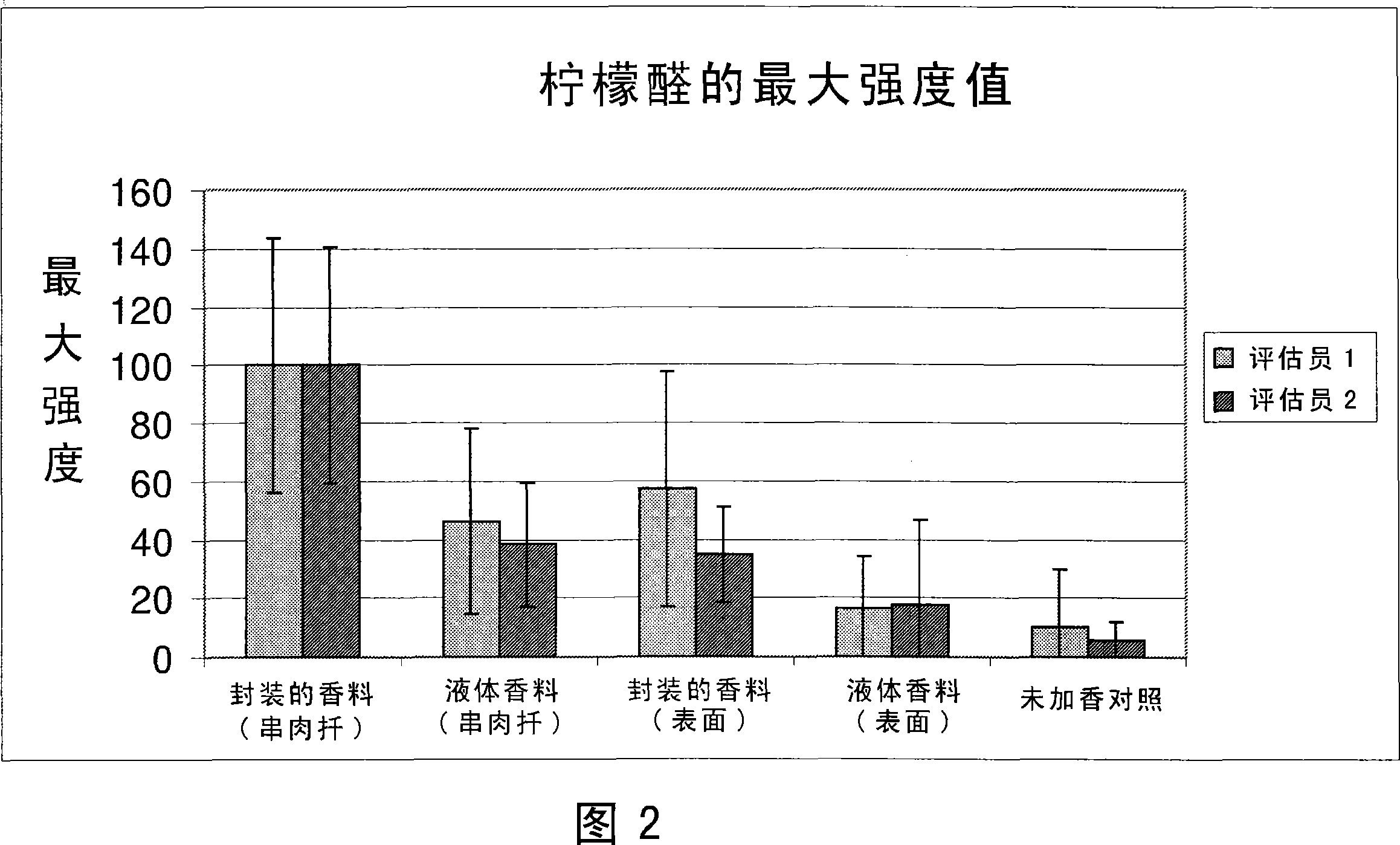

[0073] A comparative study was carried out using four different methods of applying the spice composition to chicken. After cooking on the grill at 165°F (73.8°C) for 2-3 minutes, the cooked chicken was evaluated sensorially and instrumentally.

[0074] Chicken pieces (50 g) were flavored with lemon and pepper spices at equivalent active levels (see Example 1). Fragrances are available in encapsulated form (Example 1) and liquid form (commercially available). According to the procedure in Example 2, the spices were applied to the fork using microencapsulation or directly using liquid spices. Additionally, spices can be applied to the surface of the chicken in the form of corn oil based and either encapsulated spice or liquid spice marinades. The spice composition was applied equally to each piece of chicken, and the method of application was as follows:

[0075] A) The yeast-encapsulated spice in the coating on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com