Dissection bone plate for locking wall agnail angle after acetabulum

A bone plate and acetabular technology, applied in the direction of outer plate, fixer, internal bone synthesis, etc., can solve the problems of large soft tissue damage, complicated fixation, medical accidents, etc., achieve easy placement and removal, reduce surgical incision, prevent Effects of Malpractice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

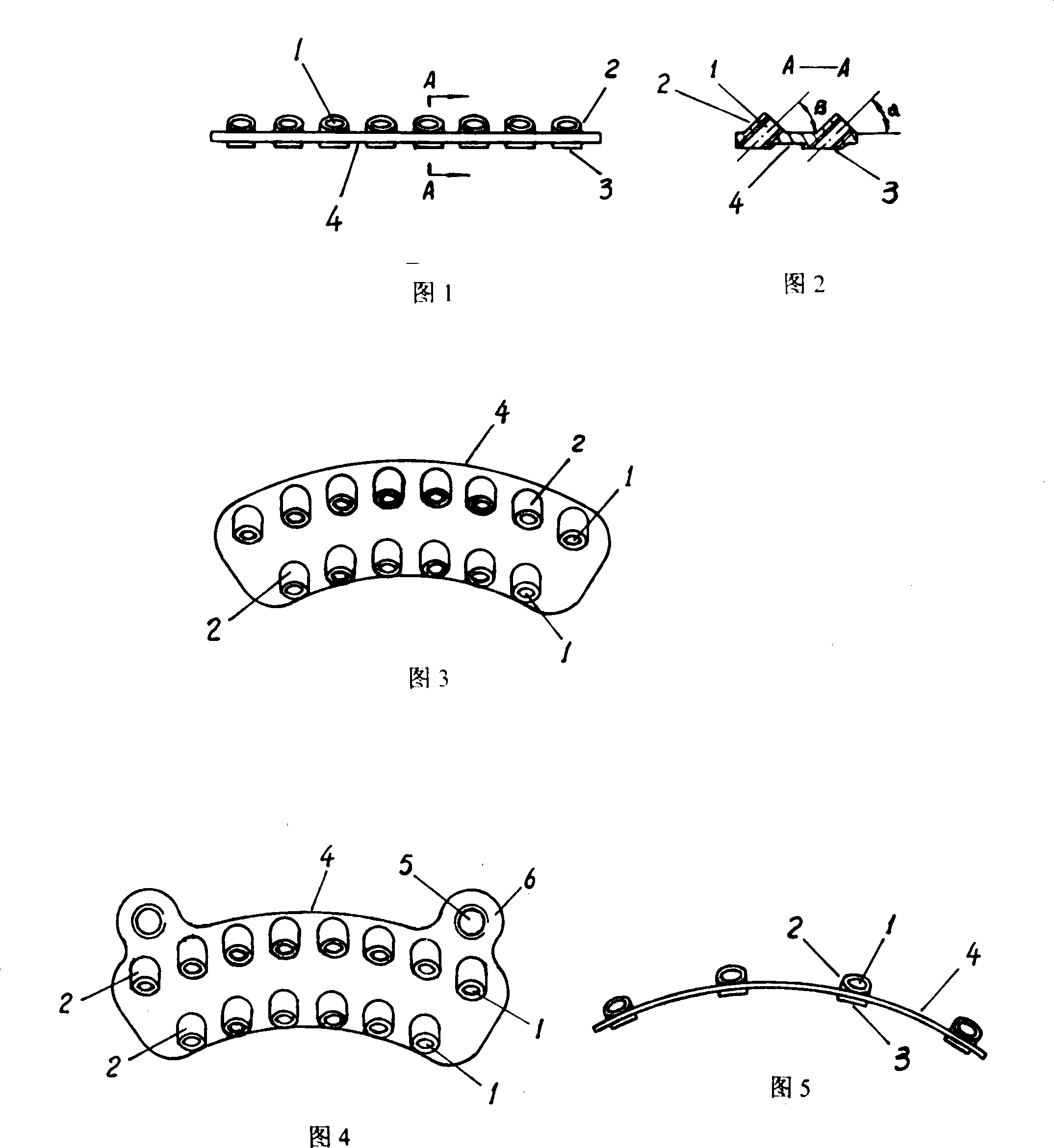

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings of the embodiments.

[0020] Referring to Fig. 1-Fig. 3, in embodiment one, plate body 4 is flat fan-shaped plate, adopts medical stainless steel to make, and steel plate thickness is 0.8-2mm, and width is 20-25mm, and length is 40-70mm, and screw hole 1 Bosses are provided on both plate surfaces of the site, the height of the boss 3 on the side that is in contact with the bone surface is 0.5mm, and the height of the boss 2 on the other side is 1mm. The plate body 4 is provided with two rows of screw holes 1, the number of screw holes 1 on the side of the plate body 4 opposite to the acetabular rim is 6, and the number of screw holes 1 on the opposite side is 8. The screw holes 1 can all be through holes, or all can be threaded holes, but preferably the through holes and the threaded holes are arranged alternately. The advantage of the screw hole being a throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com