Annular filling method for space between freezing pipe and surrounding rock

A technology for freezing pipes and surrounding rocks, which is applied in earthwork drilling, shaft equipment, mining equipment, etc. It can solve problems such as collusion and flooding accidents, and achieve the effects of short construction period, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

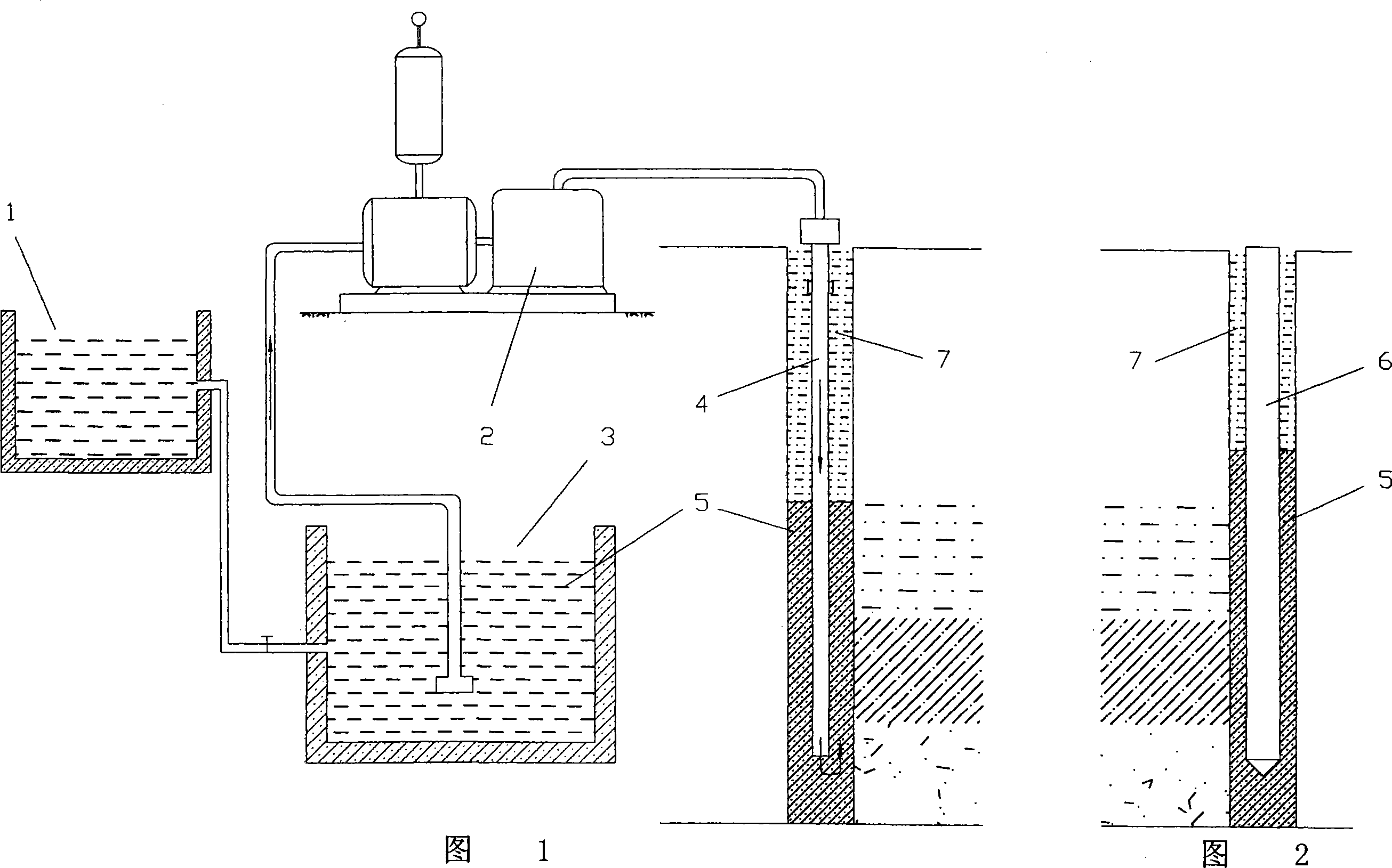

[0011] The present invention comprises the following steps: (1), the preparation of cement slurry 5: 1., raw material is cement (P.032.5), water, clay or bentonite, retarder, alkali powder, amine powder, nitrile powder, and water: cement is 1:0.5~1:1; the amount of clay or bentonite is 5%-10% of the cement amount; the retarder uses GK-4A high-efficiency retarding water reducer, which is 2.5%-3% of the cement amount, alkali powder, amine Powder and nitrile powder are 1% of the cement consumption, and the above are weight ratios; ②, pour the raw materials into the stirring tank 1 according to the stated ratio and stir for 2-10 minutes, and put them into the slurry storage tank 3 after stirring evenly ; (2) Filling method: ① After the final hole of the frozen hole, adjust the clay slurry in the frozen hole until the specific gravity of the clay slurry flowing out from the frozen hole is 1.05-1.15g / cm 3 When the time stops, the performance of the clay slurry is: specific gravity 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap