Fluid piston pump

A piston pump and piston technology, which is applied in the field of non-pre-pressure passive suction-discharge synchronous fluid piston pump, can solve the problems of inability to spray and discharge, complex structure, and inability to carry out spray-discharge and suction at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

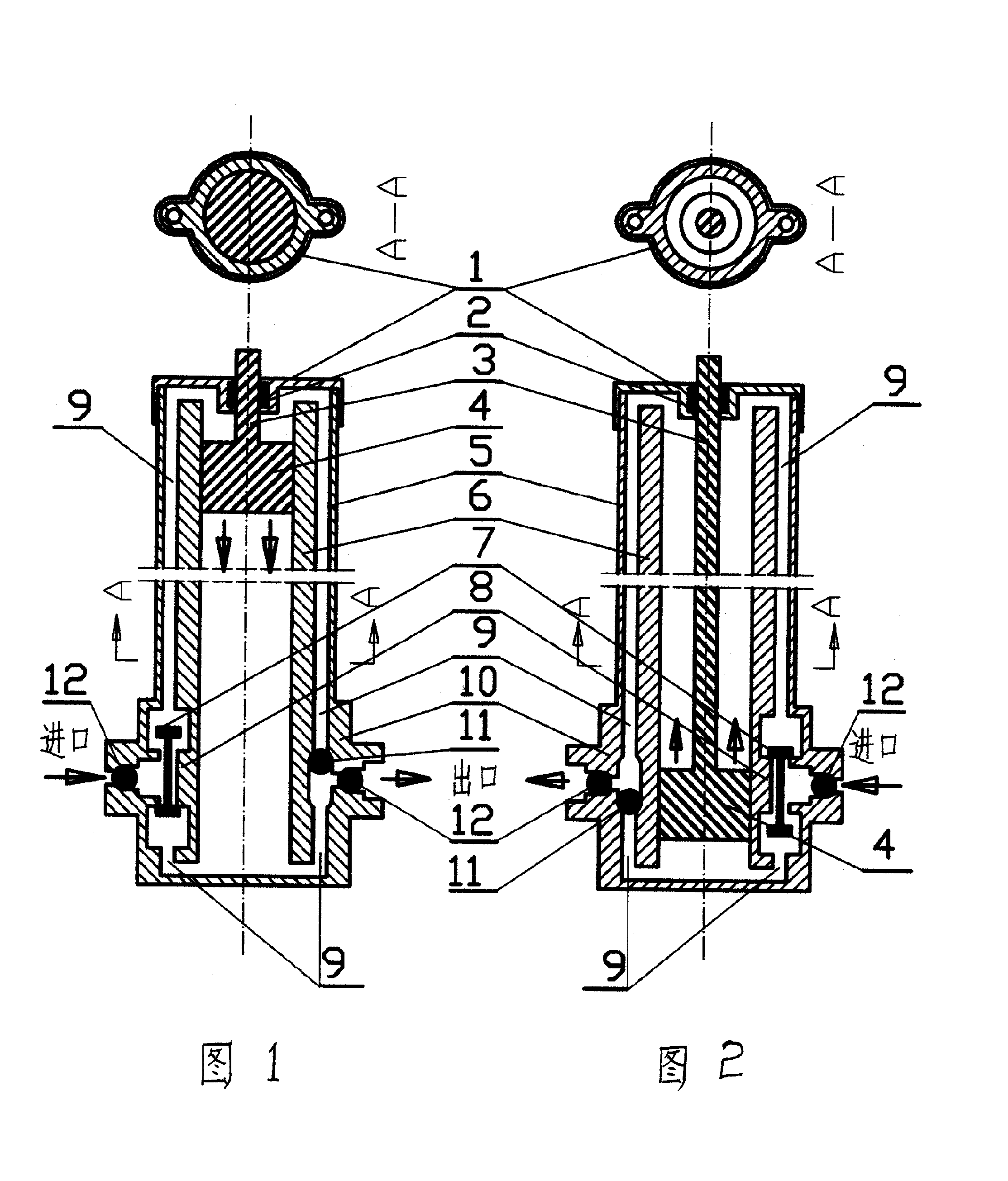

Image

Examples

Embodiment Construction

[0018] 1. Keep the inlet unobstructed, and install a hose and joint at the outlet of the valve seat 10, which can be used as a quick pump;

[0019] 2. Connect the pipeline at the inlet and feed the fluid to be sucked, and connect the corresponding pipeline and nozzle at the outlet, which can be used as a simple fire sprinkler, agricultural (household) sprayer, toy water gun, etc.;

[0020] 3. Equipped with corresponding manual or motorized devices, it can be used as a water pump and an oil pump.

[0021] In the specific implementation, there are the following three situations, which can be applied according to actual needs:

[0022] ①The pump body 5 is fixed, and the piston push-pull rod 3 moves telescopically;

[0023] ②The piston push-pull rod 3 is fixed, and the pump body 5 reciprocates;

[0024] ③Piston push-pull rod 3 and pump body 5 are not fixed.

[0025] The invention is an innovative breakthrough to the traditional fluid piston pump. The large-scale one can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com