Method for regulating and controlling water pressure of seepage flow water outlet end

A technology for water outlet and water outlet, which is applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc. It can solve problems such as pipeline leakage, affecting test results, and low precision of differential pressure sensors. achieve low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

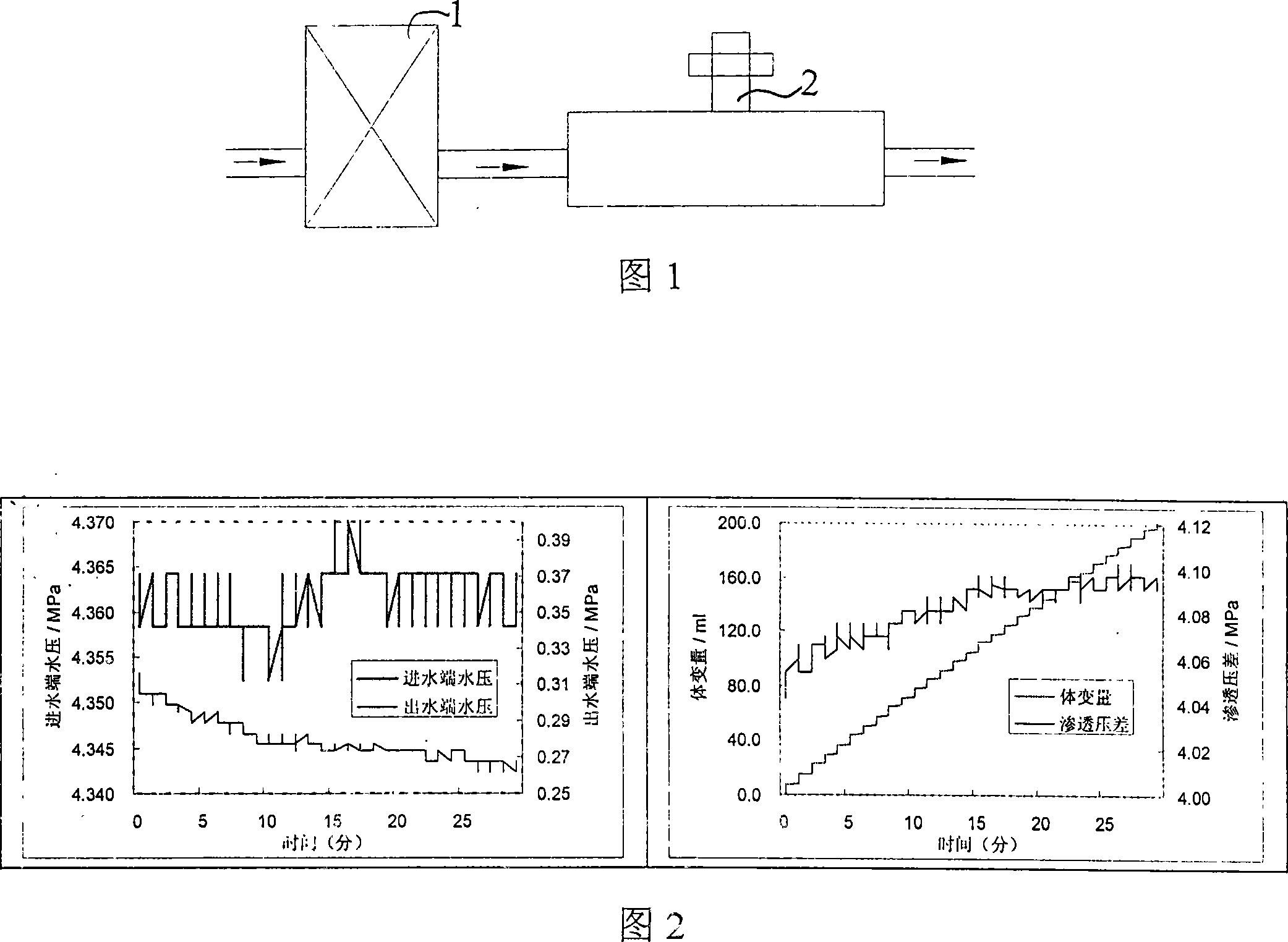

[0011] Referring to Figure 1, the water pressure control method at the seepage outlet end, the method is to connect the pipeline filter 1 at the seepage outlet end of the sample, and the manual speed control valve 2 connected with the pipeline filter to regulate the flow rate at the seepage outlet end, so that Maintain a steady flow at the outlet. As long as the water pressure at the seepage inlet end is kept constant, when the seepage flow of the sample reaches a balance with the adjusted flow rate, a stable water pressure value can be generated at the seepage end, and then a stable water pressure difference can be formed at both ends of the sample. When the pressure difference and flow rate of seepage water remain unchanged, the permeability test in this period conforms to Darcy's law, and then the permeability index of rock mass under corresponding conditions can be obtained.

[0012] Figure 2 is the actual measurement results for a certain lithology sample, and the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com