Method for recrifying mold model data

A technology of model data and molds, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve difficult problems and achieve the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

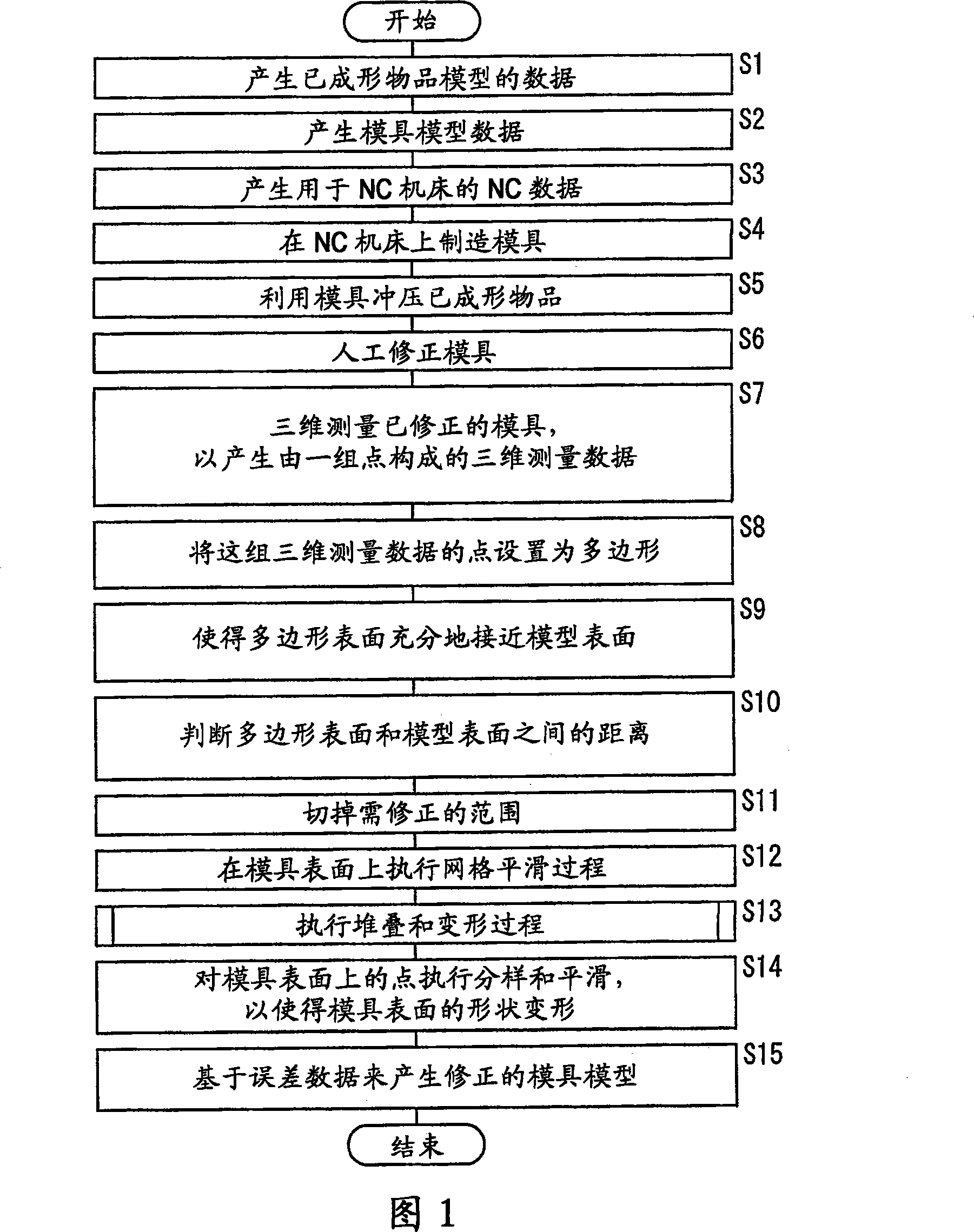

[0035] A method of correcting mold model data according to an embodiment of the present invention will be described below with reference to FIGS. 1 to 15 .

[0036] In step S1 shown in FIG. 1 , the desired shaped article is designed, and the data of the shaped article model is generated.

[0037] In step S2, the data of the mold model is generated on the CAD system based on the data of the formed article model.

[0038] In step S3, NC data for controlling an NC machine tool is generated based on the mold model data.

[0039] In step S4, a mold is manufactured by a numerically controlled machine tool based on the NC data.

[0040] In step S5, a formed article as a prototype article is punched using the manufactured die.

[0041] In step S6, the prototype article and the forming surface of the mold are observed and analyzed, and manual corrections are made to the mold. Specifically, observe and analyze the folds, cracks and dimensional errors of the prototype, and observe and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com