Method for producing in a tfp method one-or multi-layer layer fibre preforms and a support layer

A multi-layer fiber and preform technology, which is used in the field of producing single-layer or multi-layer fiber preforms and cushion layers through the TFP process, can solve problems such as fiber bundle damage, and achieve the effect of easy detachment or separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

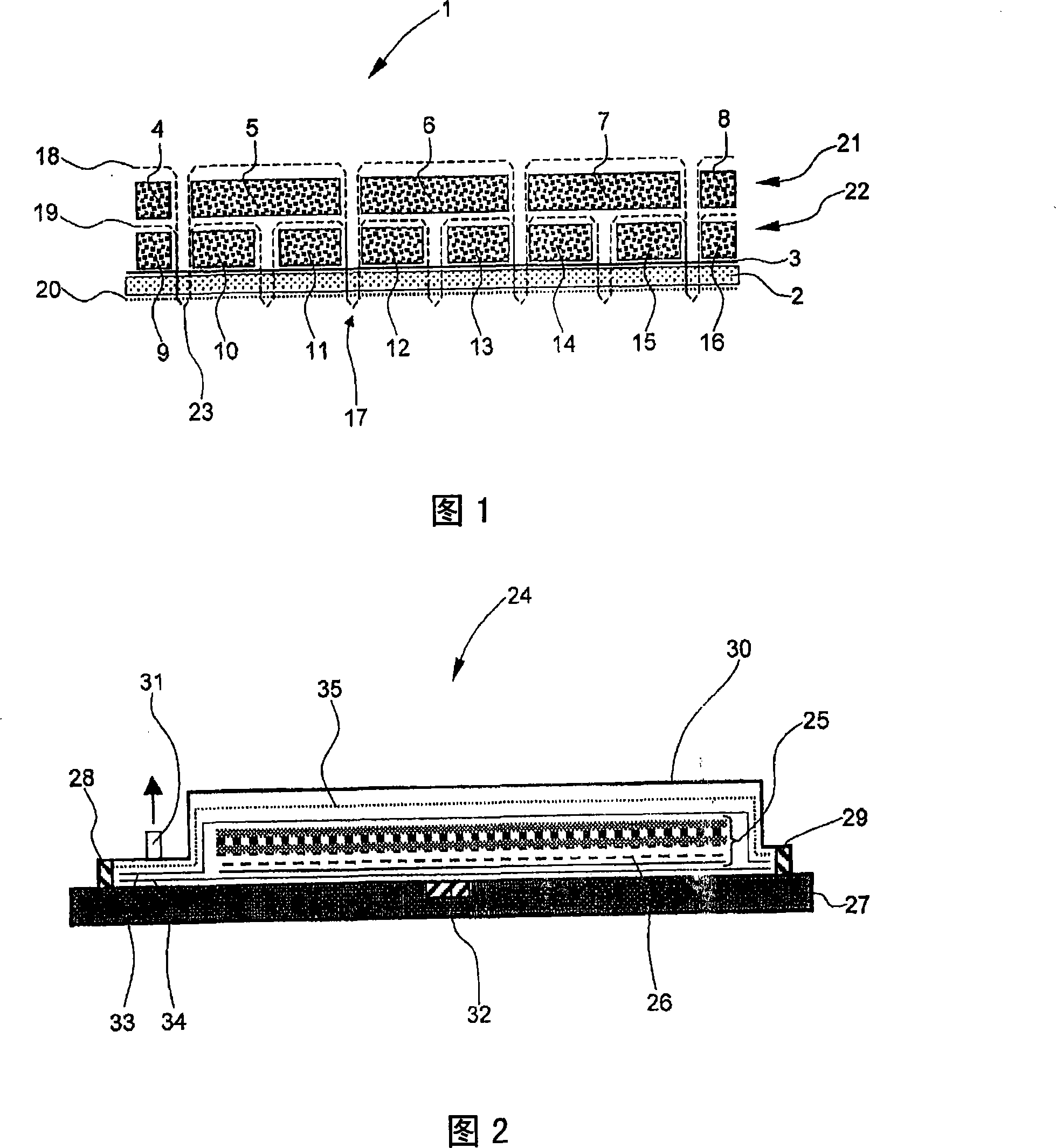

[0065] The method according to the invention and the backing layer according to the invention will be explained in more detail with reference to FIGS. 1 and 2 .

[0066] Figure 1 shows a cross-sectional view through a fiber preform with a release layer formed by the TFP process.

[0067] The fiber preform 1 has a backing layer 2 therein and a release layer 3 arranged on the backing layer 2 . The release layer 3 is formed, for example, by a thin-layer PTFE film or the like having good non-stick properties.

[0068] In addition, the release layer 3 can also be formed by a film of other polymers (such as polyethylene, polypropylene, etc.) with good non-stick properties. Furthermore, the release layer can be formed by a sheet-like form, for example textile fibers, provided with a release agent, such as a release coating or the like. The release layer 3 can optionally be produced by spraying or applying a non-stick material onto the backing layer 2 , so that in this case the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com