Motor and control unit thereof

A control device and electric motor technology, which is applied in the direction of AC motor control, motor generator control, electronic commutation motor control, etc., can solve the problems of large eddy current loss, large eddy current of electromagnetic steel plate, and high cost of control devices, so as to reduce cost, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] Hereinafter, a motor to which various embodiments of the present invention are applied will be described in detail with reference to the drawings.

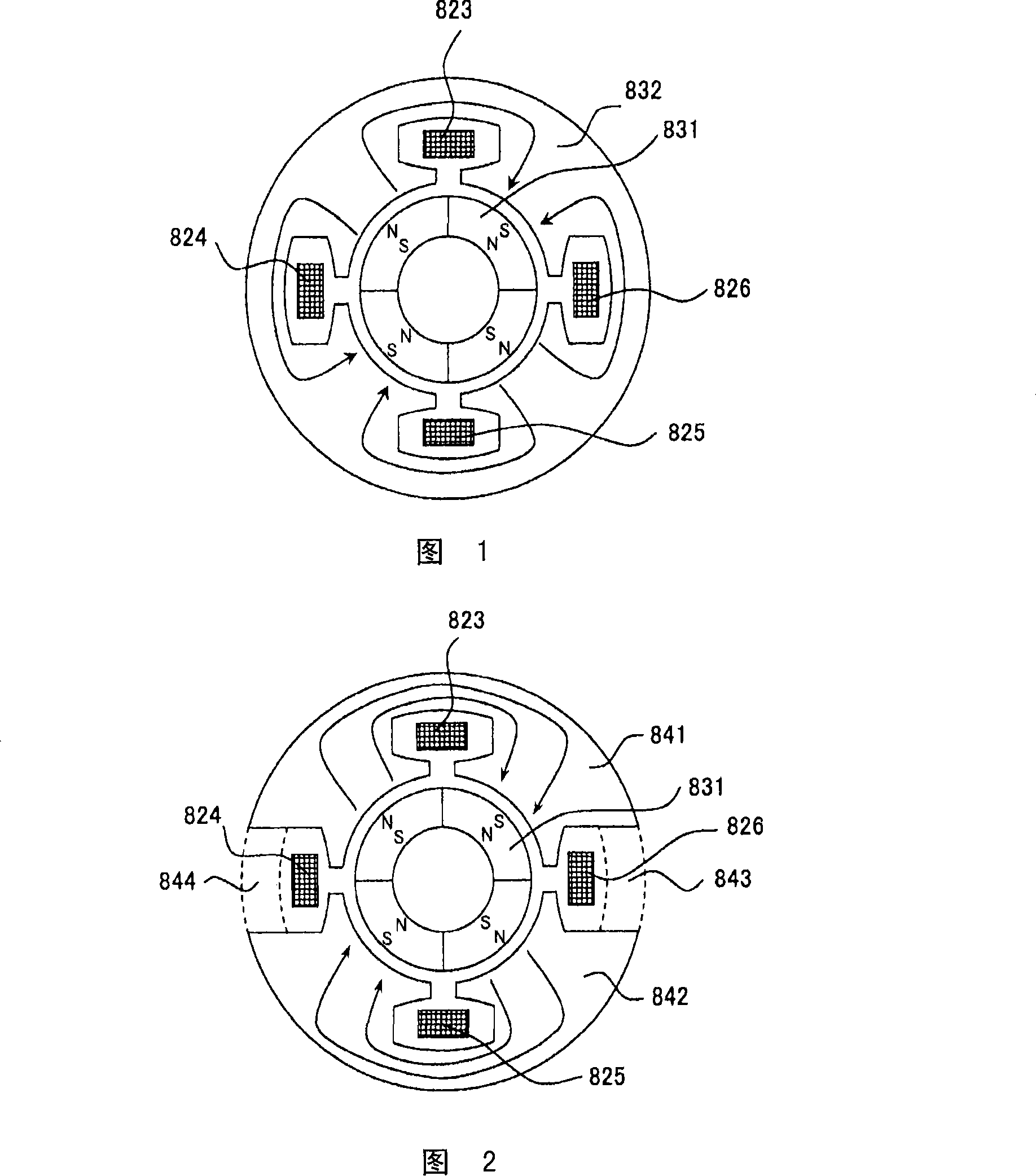

[0128] Figure 1 shows a single-phase AC, 4-pole motor. 831 is a permanent magnet of the rotor, 832 is a stator core made of soft magnetic material, and 823, 824, 825, and 826 are single-phase windings. There are several methods for winding the windings. One example is winding single-phase windings with windings 823 and 824 and single-phase windings with windings 825 and 826 . At this time, the amount of the maximum magnetic flux interlinked with the winding 823 shown in FIG. 1 is 1 / 2 of the magnetic flux of one magnetic pole of the permanent magnet 831 .

[0129] Next, FIG. 2 shows the motor in which the parts 843 and 844 shown in the wavy line part are cut out and removed from the motor of FIG. 1 . At this time, the amount of the maximum magnetic flux interlinked with the winding 823 shown in FIG. 2 is the magnetic flux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com