Sander delivering roller jack horse structure

A technology for conveying rollers and sanding machines, which is applied to roller tables, abrasive belt grinders, transportation and packaging, etc. It can solve the problems of reducing the rigidity of roller stands, being unable to adjust unilaterally, and reducing the accuracy of operation, so as to improve convenience and reliability, convenient adjustment of the amount of sanding, and the effect of small matching clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

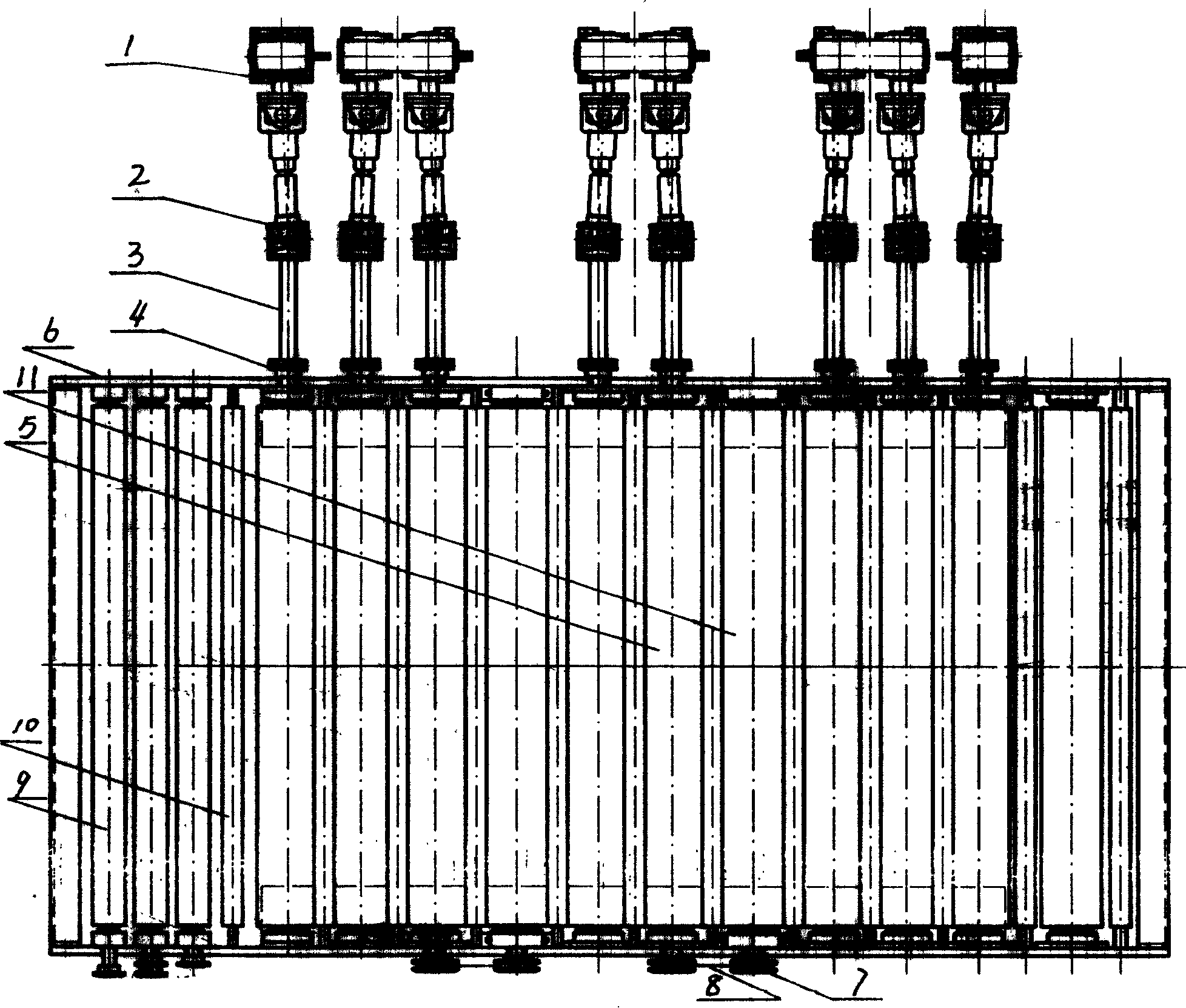

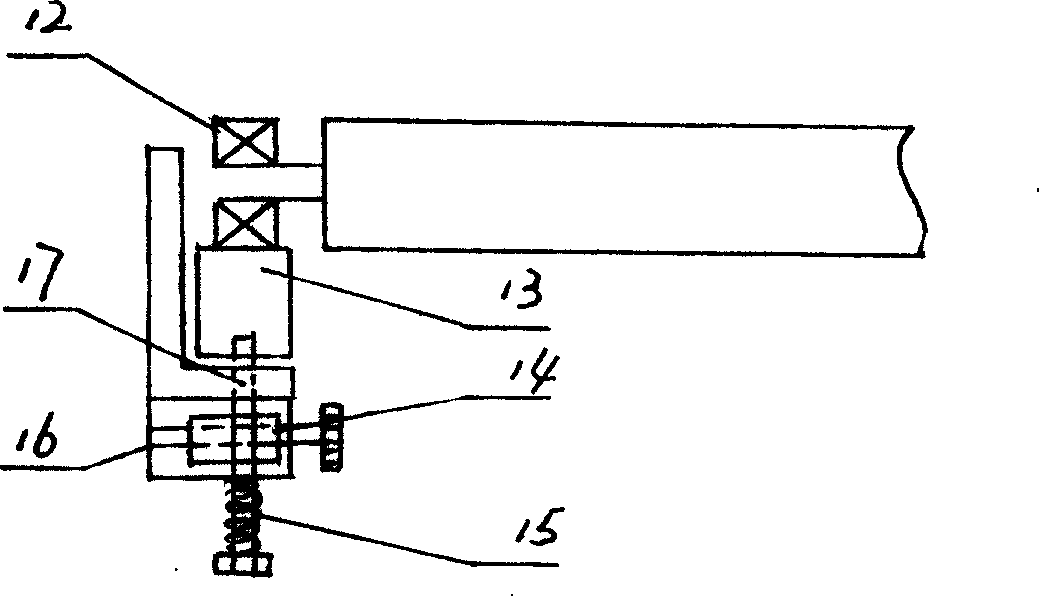

[0009] Embodiment 1: with reference to attached figure 1 and 2 . Sander conveying roller stand structure, 2 or more conveying rollers 5 are positioned on the shaft seats in the roller stand 6, the processing and manufacturing of conveying rollers 5 is the prior art, and will not be described here. Two or more conveying rollers 5 are respectively connected to the reduction box 1 located outside the roller stand through the conveying coupling shaft 3 and the universal joint 2 (one end of the two or more conveying rollers 5 adopts the conveying coupling flange 4 and the conveying One end of the coupling shaft 3 is connected, and the other end of the conveying coupling shaft 3 is connected to the output shaft of the reduction box 1 through the universal joint 2. One or two or more lower idlers 11 are respectively distributed between the multiple conveying rollers 5 and Through the transmission mechanism (sprocket, chain transmission mechanism), the conveyor roller 5 drives the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com