Equipment and method of automatically cutting work piece skirt border

A technology for processed objects and automatic cutting, applied in metal processing and other directions, can solve the problems of cutting off skirt waste materials, manual inability to accurately control thickness, poor processing quality, etc., to improve production efficiency and product quality, real-time high-speed detection and control. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

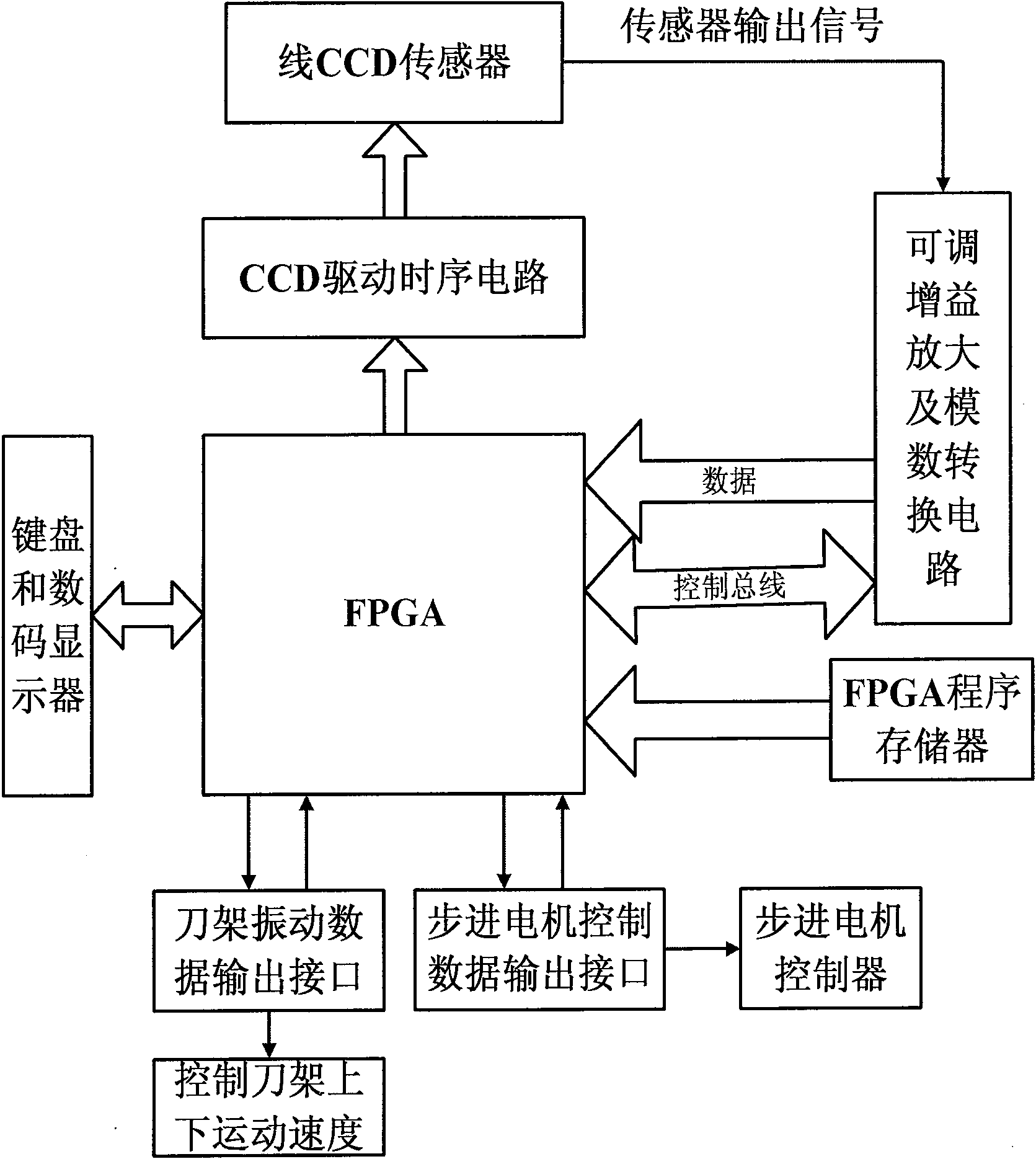

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

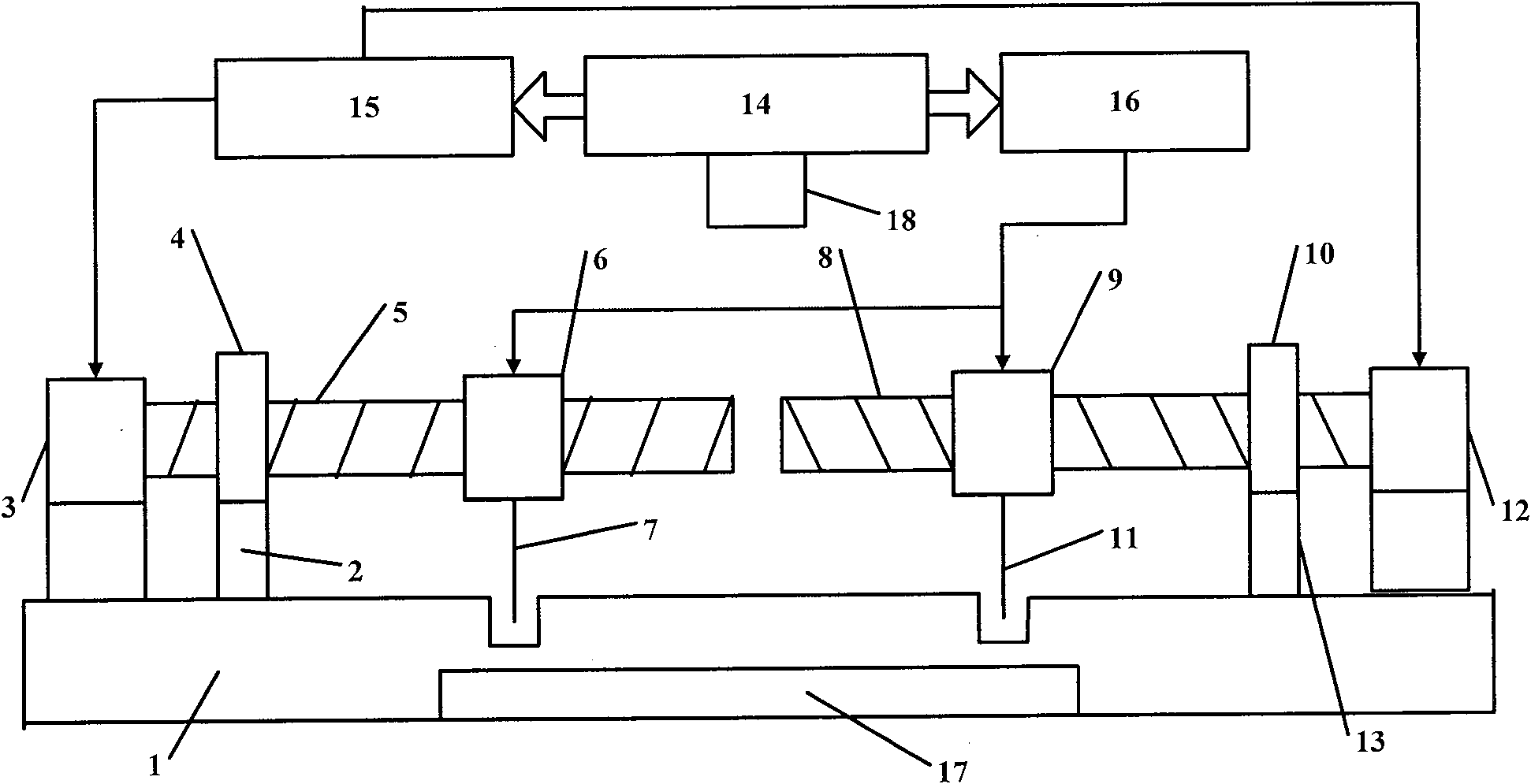

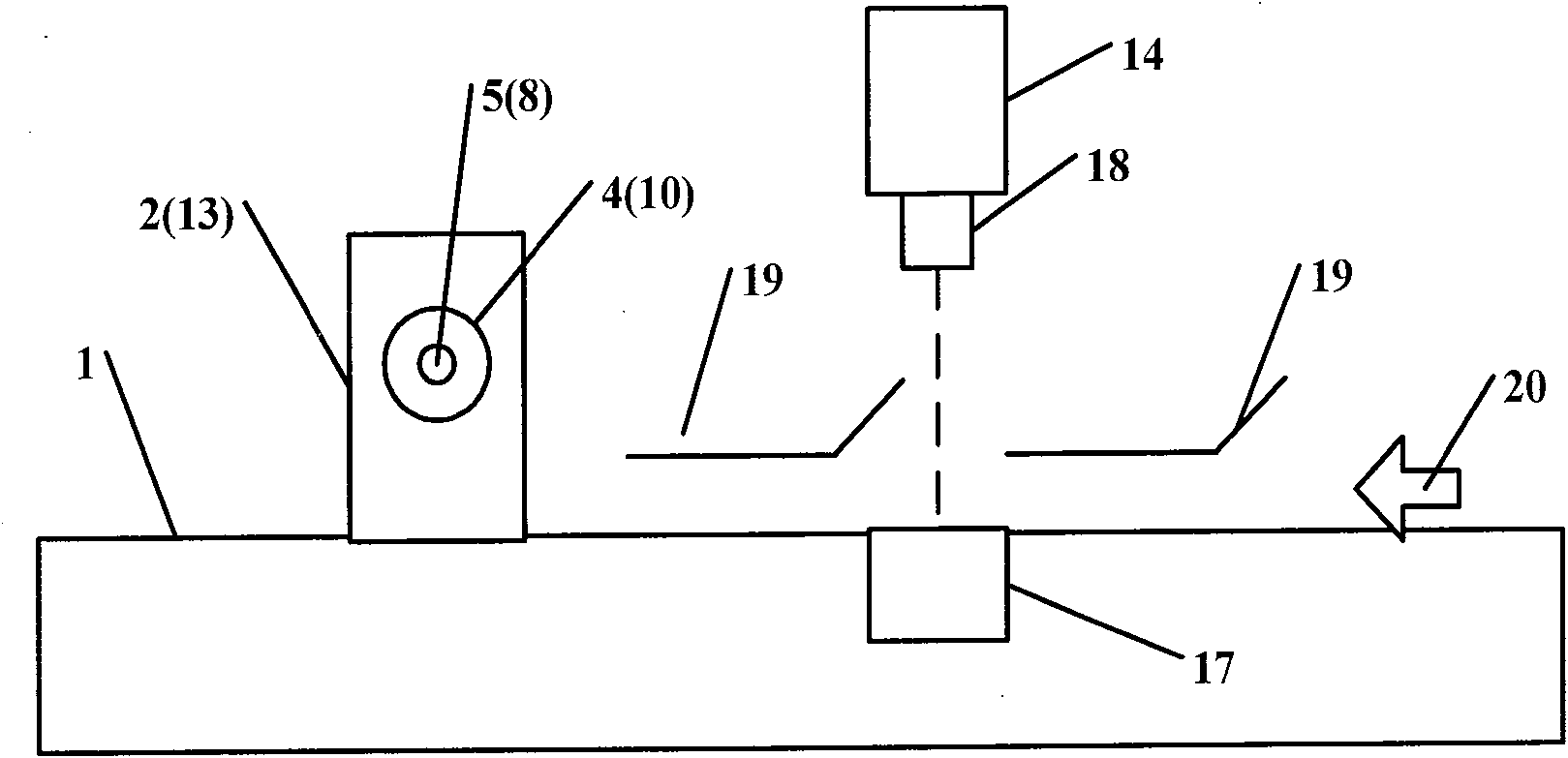

[0025] The processed object is kelp; first coordinate positioning, then enter the main program loop, detect the data, and send it to the memory inside the FPGA; then perform digital filtering to overcome the influence of interference signals in the image signal; then perform thickness quantification to calculate the The axial thickness distribution of the left lead screw 5 and the right lead screw 8; according to the set cutting thickness requirements, determine the coordinate points of the left moving nut and knife rest 6 and the right moving nut and knife rest 9, and drive the left stepping motor and the bracket The left stepping motor on the 3 and the right stepping motor and the right stepping motor on the support 12 make the left cutter 7 and the right cutter 11 move to the coordinates of the specified thickness;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com