A laying device suitable for z-shaped composite fuselage blanks

A composite material and laying technology is applied in the field of laying devices of composite material Z-shaped fuselage bulkhead blanks, which can solve the problems of poor quality consistency and low laying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

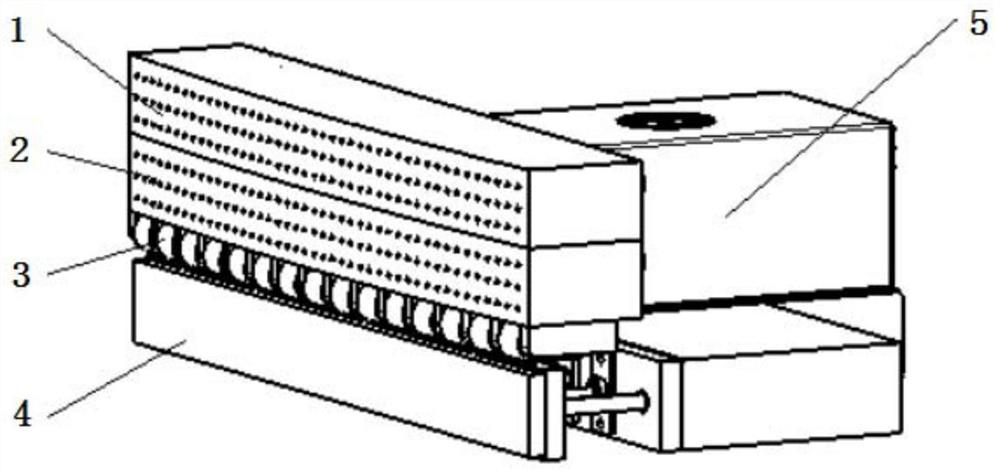

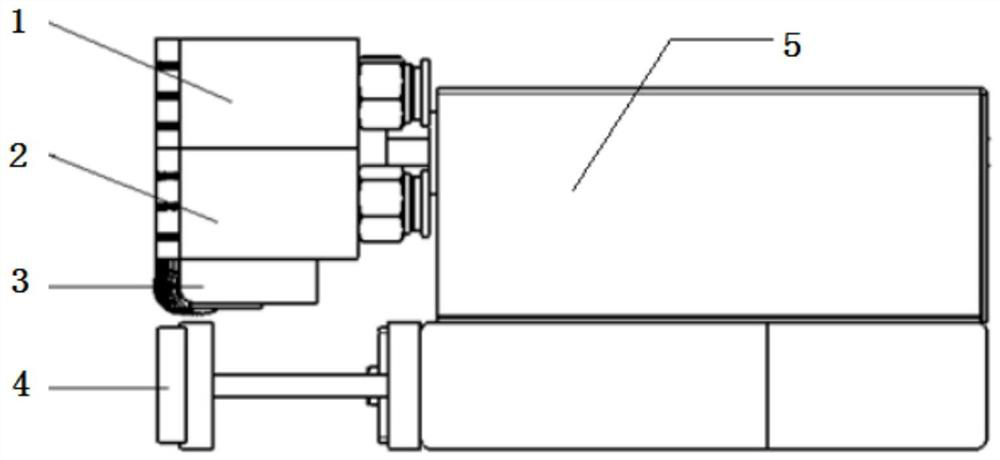

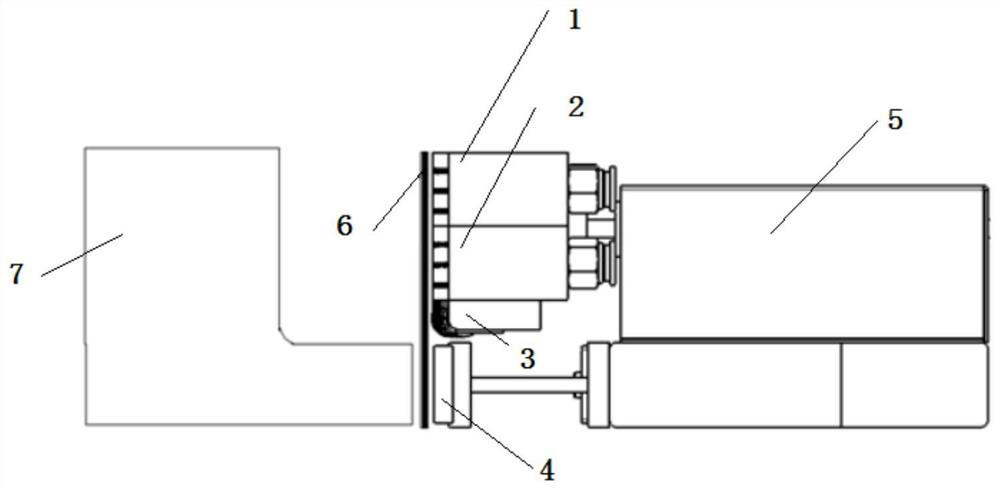

Image

Examples

Embodiment

[0024] In the embodiment, using image 3 M21C prepreg (single-layer thickness 0.19mm, width 150mm, remove the separator paper and separator of the prepreg sheet), turn on the vacuum adsorption function of the laying device, absorb the prepreg sheet, and the manipulator Drive the laying device to position the material, and the positioning and compacting mechanism will compact the material on the flange of the mold, the forward pushing mechanism will move forward, and the roller group will compact the material at the outer R. The compaction process here It is necessary for the vacuum chamber to maintain a vacuum adsorption state all the time to ensure that the sheet is under tension, which is beneficial to increase the degree of compaction at the R angle. The forward pushing mechanism continues to move forward, presses the sheet into a Z shape, and compacts the sheet at the inner R. After compaction, the forward pushing mechanism retreats, and the laying action is completed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com