LED application product automation production line

A technology for automated production lines and products, applied in the direction of assembling printed circuits with electrical components, testing single semiconductor devices, etc., can solve problems such as unstable quality, improve the effect of use, and solve the test of real usability tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

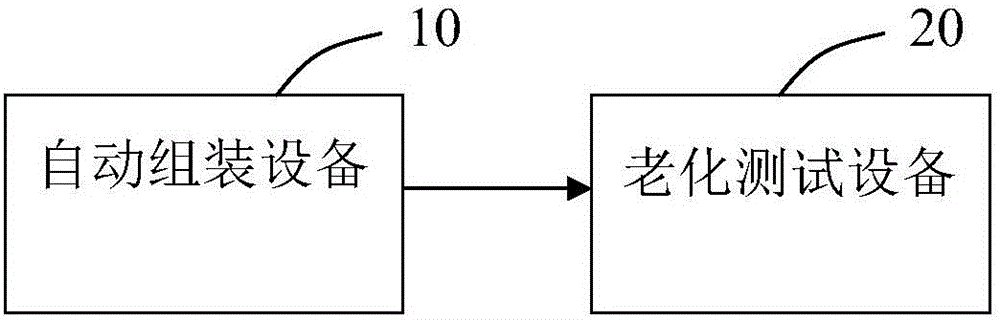

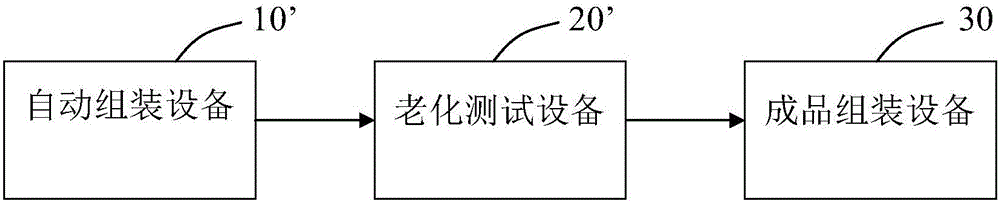

[0025] Such as figure 1 Shown is a schematic diagram of an embodiment of an automated production line for LED application products of the present invention. In this embodiment, the automated production line includes automatic assembly equipment 10 and burn-in testing equipment 20, wherein the automatic assembly equipment 10 is used to assemble LEDs and electronic components to circuit boards to form PCB boards, and the burn-in testing equipment 20 is used to The PCB board is subjected to power-on aging test, and the automatic assembly equipment 10 and the aging testing equipment 20 are connected by a conveyor belt or a manipulator, so as to transfer the PCB board assembled by the automatic assembly equipment 10 to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com