Medicial film machine

A technology of medicine film and rack is applied in the field of pharmaceutical equipment to achieve the effect of reducing labor intensity, economical and practical, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

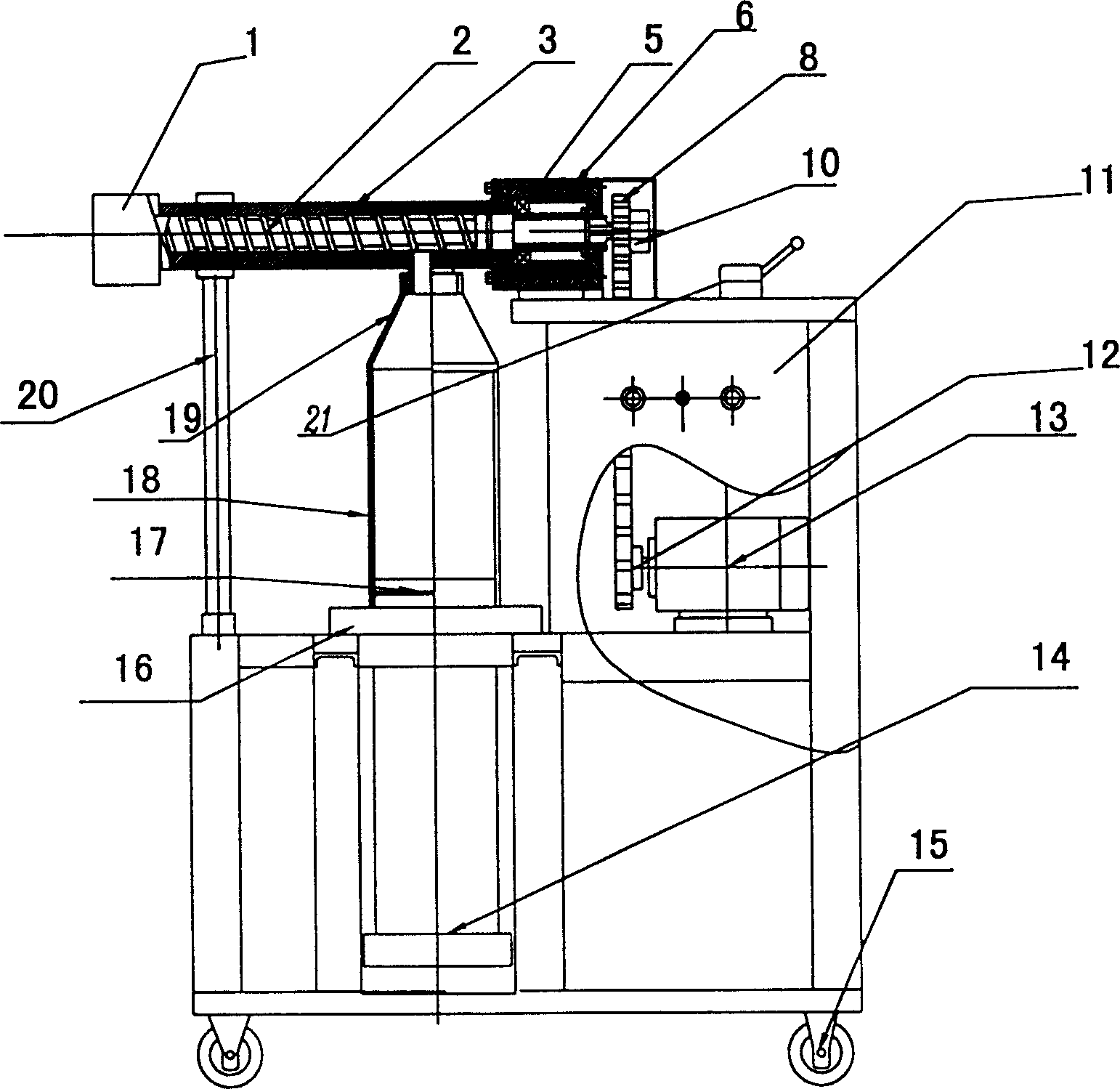

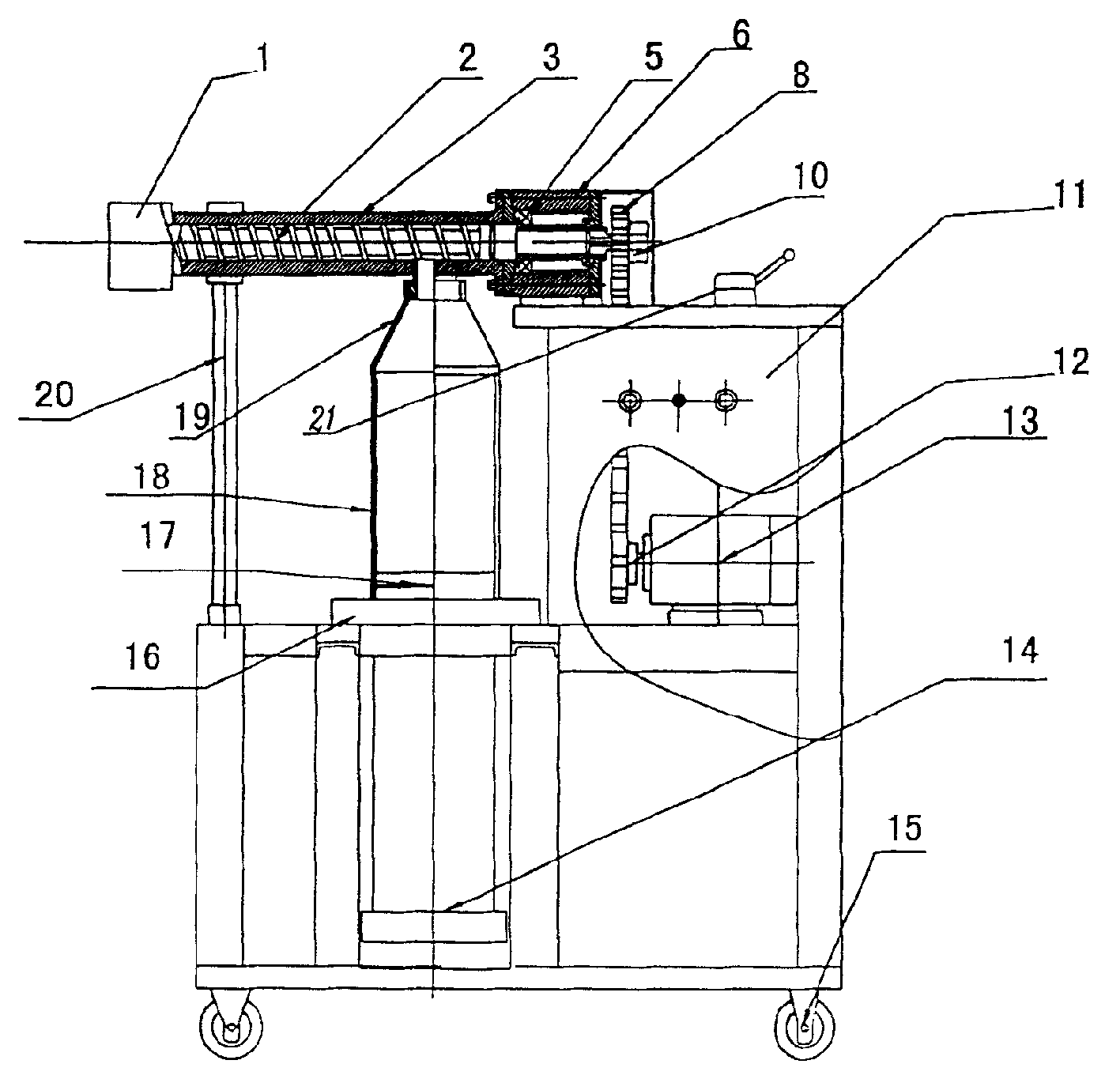

[0012] The drug film machine of the present embodiment is as figure 1 Shown, on frame 11, horizontal screw conveyor 3 is housed. The tail end of the screw 2 of the screw conveyor 3 is supported in the bearing 5 and fixedly connected with the synchronous toothed wheel 10 . The bearing 5 is installed on the frame 11 through the bracket 6 . The synchronous toothed wheel 10 is engaged with the driving wheel 12 of the motor 13 through the synchronous toothed belt 8 . Motor 13 is fixedly installed in frame 11 rear parts. The front end of the screw conveyor 3 is supported on the vertical strut 20 . In order to facilitate the movement, universal wheels 15 are installed at the bottom of the frame 11 .

[0013] The machine barrel of screw conveyer 3 rear ends is shaped on the inlet hole that communicates with medicine pressing device material cylinder 16. The medicine pressing device 16 is mainly composed of a material cylinder 18 and an air cylinder 14 . The upper end of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com