A swing arm pressing mechanism

A pressing mechanism and swing arm technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inability to realize automatic production, complex mold structure, high labor intensity, etc., to solve the problem of automatic production and simplify the mold Structure, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

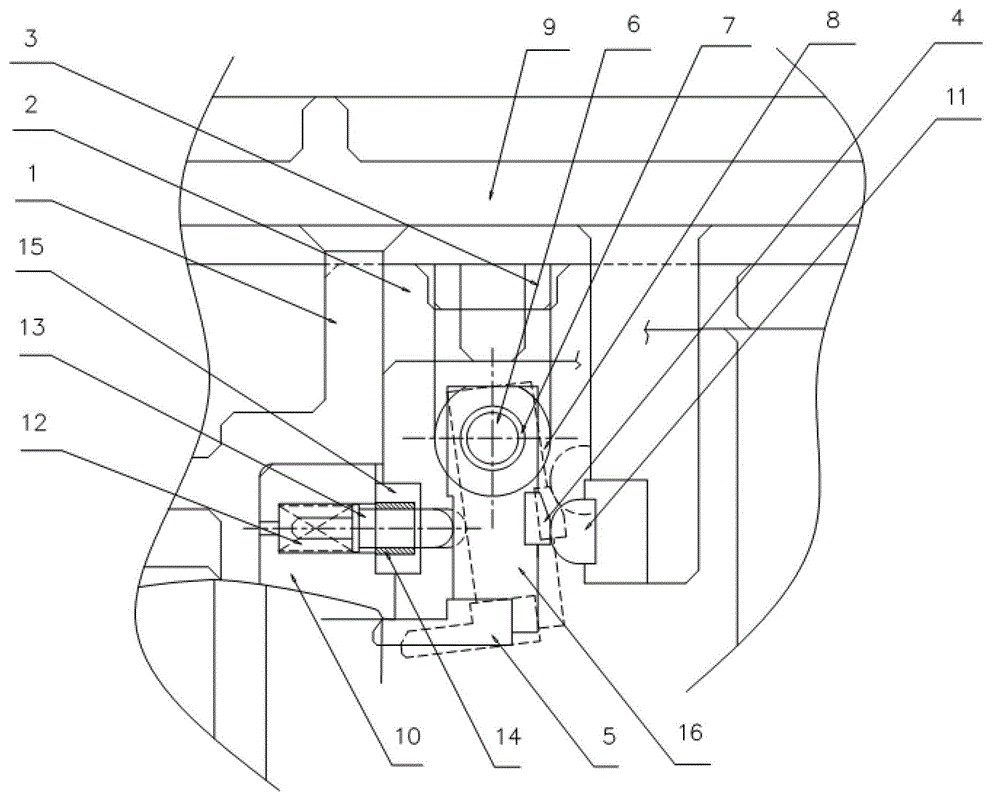

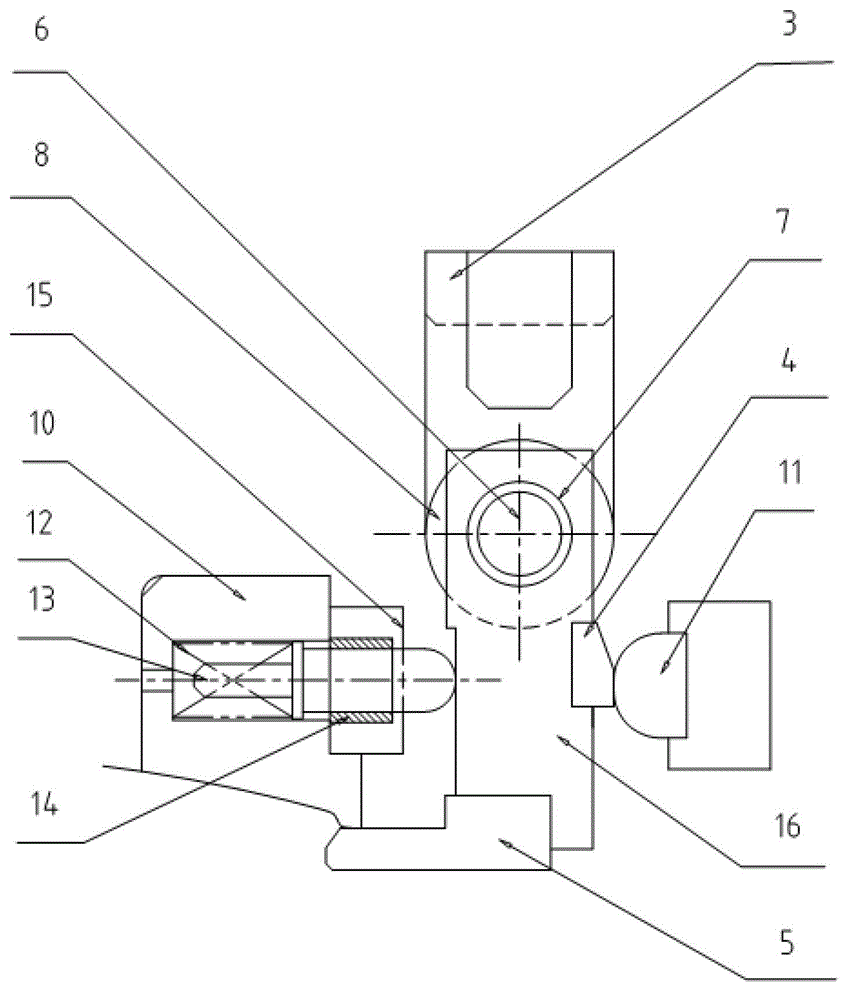

[0014] figure 1 and figure 2 It is a structural schematic diagram of a swing arm type pressing mechanism of the present invention, including an upper pressing core 1 and an upper mold base 9, the upper pressing core 1 is provided with a fixing groove 2, and an upper bracket 3 is installed in the fixing groove In groove 2, also comprise lower bracket 16, lower bracket 16 is hinged with upper bracket 3; The mold insert 5; the concave mold insert 10 is provided with an elastic ejection mechanism for ejecting the lower bracket 16; and also includes a driving mechanism for driving the lower bracket 16 to swing. The lower support 16 is hinged with the upper support through the rotating shaft 6, the rotating shaft rotating sleeve 7 and the rotating slide plate 8. The elastic ejection mechanism includes a jacking nail 13 loaded into the die insert 10, a spring 12 is arranged on the jacking nail 13, and a jacking cover plate 15 is set on the head of the jacking nail 13, and the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com