Annular bearing bottom plate grillage beam type wind-power generating tower foundation

An annular and basic technology, applied in the foundation field of the annular pressure-bearing floor well lattice beam wind power tower, can solve the problems of long overhang, waste of foundation design, uneconomical foundation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

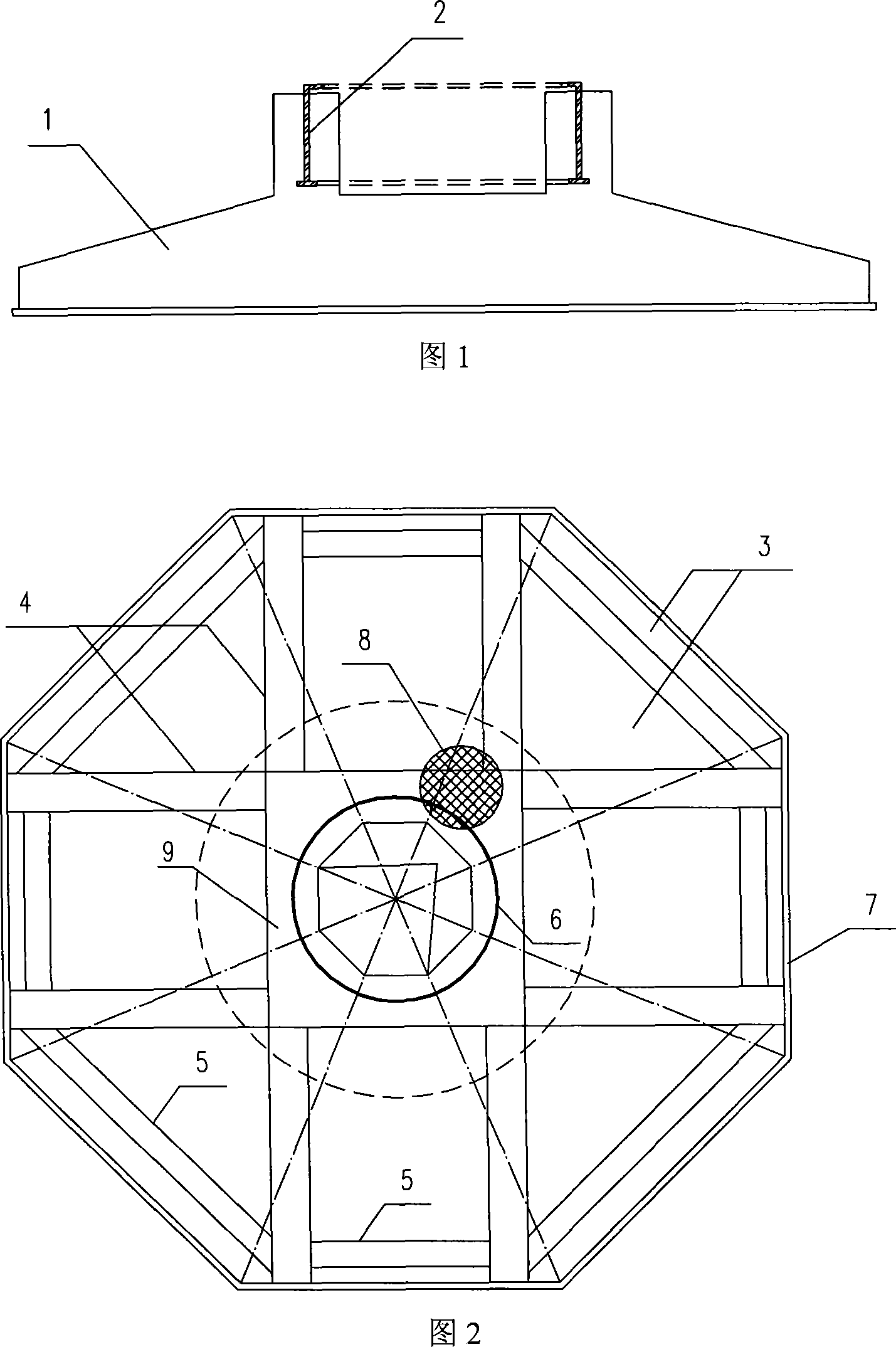

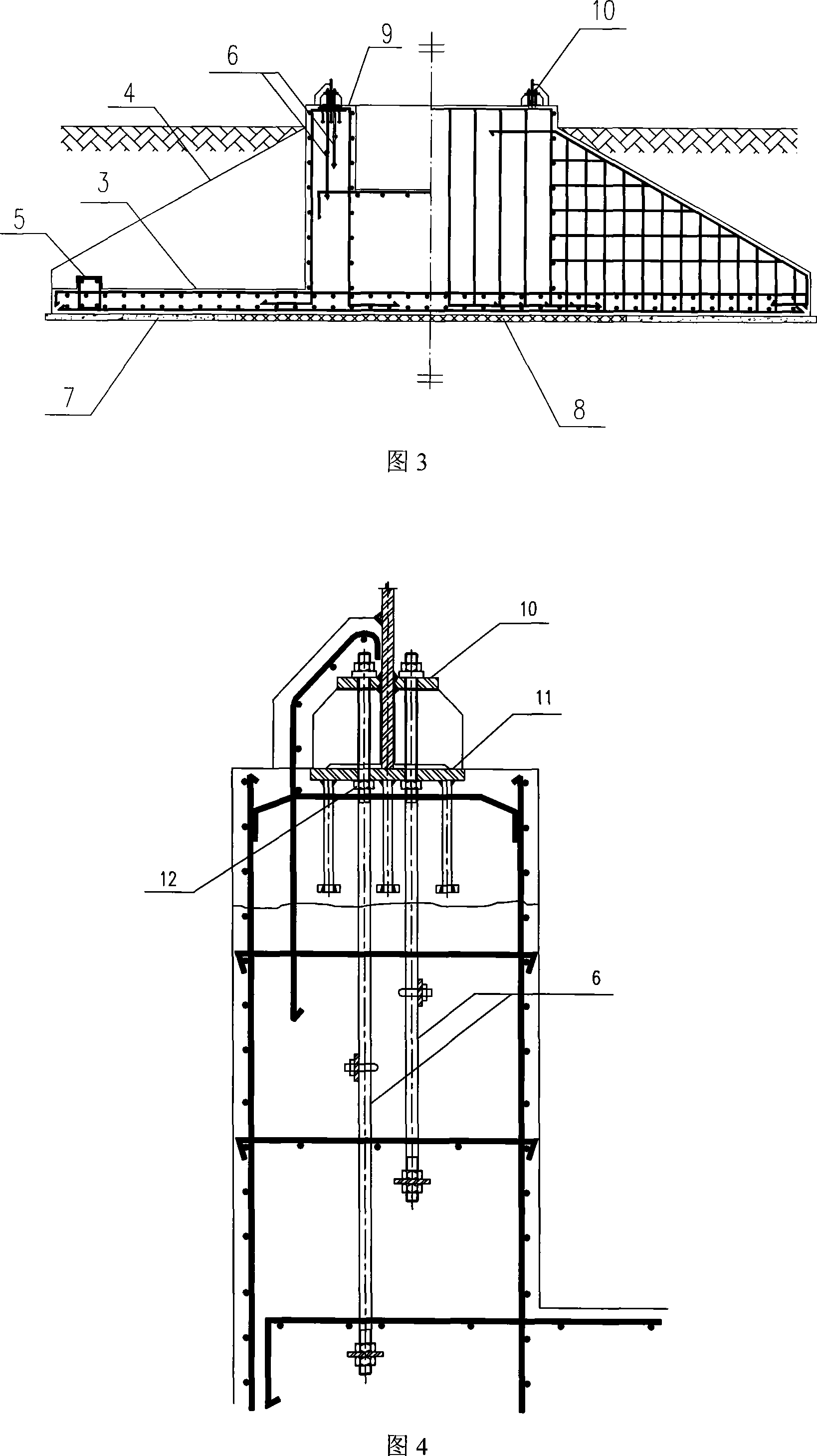

[0018] As shown in Figures 2, 3, and 4, the foundation form mainly includes annular pressure-bearing foundation floor 3, cantilever beam 4, edge beam 5, prestressed pre-embedded anchor bolt 6, annular concrete cushion 7, expanded polystyrene Plate backing plate 8. Wherein, the concrete cushion layer 7 is in the form of a ring, and an expanded polystyrene plate backing plate 8 is embedded in its center, and a concrete base plate 3 and a concrete base plate 3 are arranged above the cushion layer 7 and the expanded polystyrene plate plate 8 A concrete foundation center tube 9 is arranged above the middle part, and the cantilever beam 4 protrudes outward from the concrete foundation center tube 9, and the two ends of the edge beams 5 are connected to the cantilever beam 4 to form a well-shaped structure; Anchor bolts 6 are evenly buried, and the number of anchor bolts 6 is 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com