Construction method of daylighting hyperthermia booth

A construction method and greenhouse technology, applied in the field of greenhouses, can solve the problems of high construction difficulty, poor firmness, affecting production, etc., and achieve the effects of good thermal insulation effect and high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

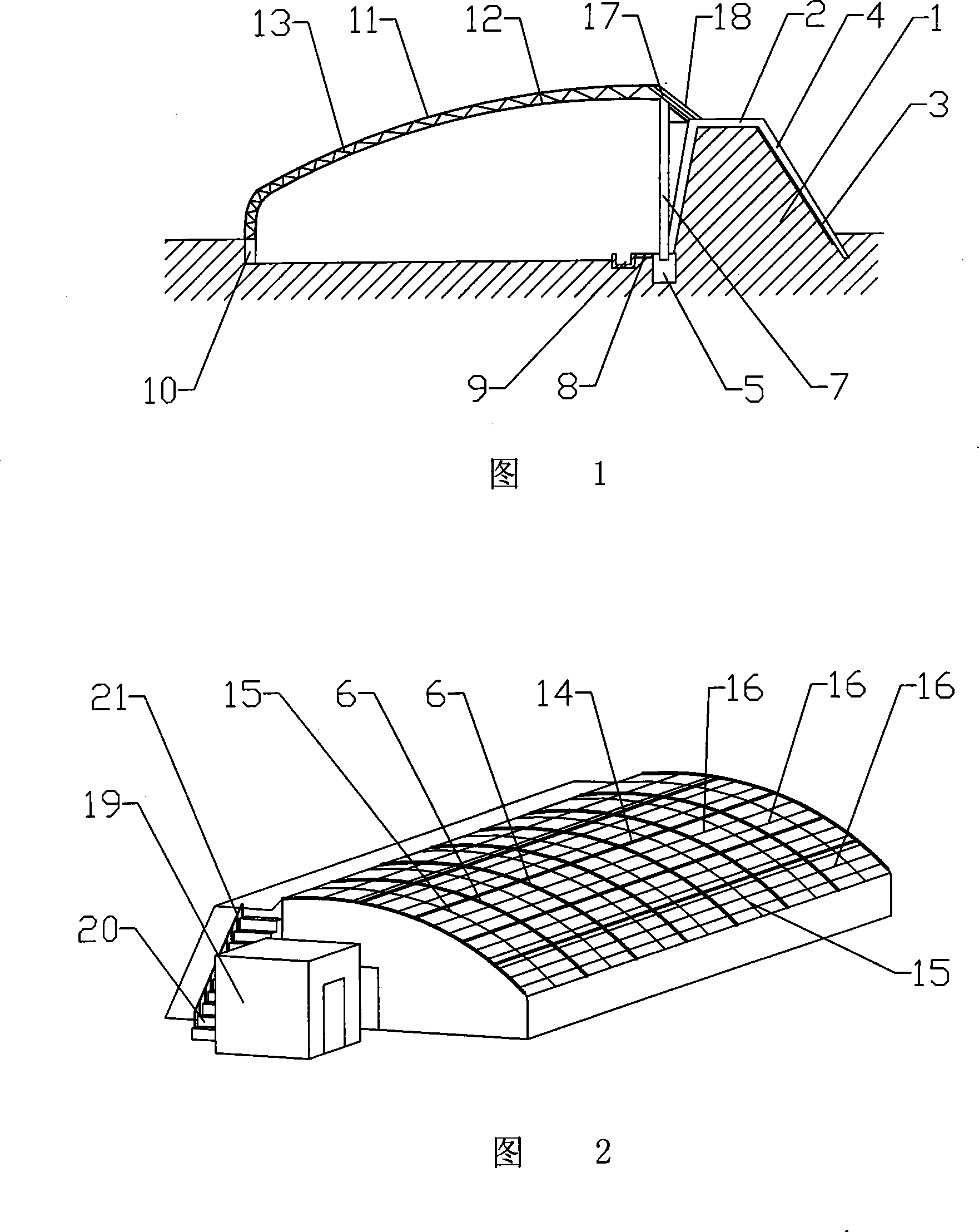

[0026] Embodiment: As shown in Fig. 1 and Fig. 2, a construction method of a solar high-temperature greenhouse, the greenhouse includes a wall

[0027] 1. The left and right side walls, scaffolding, and scaffolding include several steel frames. The construction method includes the following steps:

[0028] a. Determine the foundation and size of the greenhouse and wall 1. The north-south span of the greenhouse is 11 meters, and the east-west length is 100 meters. Clean up the garbage at the foundation, and then use the chain rail car to compact the foundation of wall 1 to build wall 1 and left For the side wall and the right side wall, the width of the top of the wall 1 is 1.5 meters. During the construction of the wall 1, four 3-meter-long floors were placed obliquely on the wall 1 at a height of 1.8 meters in advance. The inclination of the floors The slope of the ground inside and outside the greenhouse is the same. The inner ground of the greenhouse is dug 1.2 meters and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com