Regulation of the temperature of hot gas of a gas turbine

A technology of gas turbine and hot flue gas, applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of reduced life, damage, power loss, etc., and achieve the effect of simplifying calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

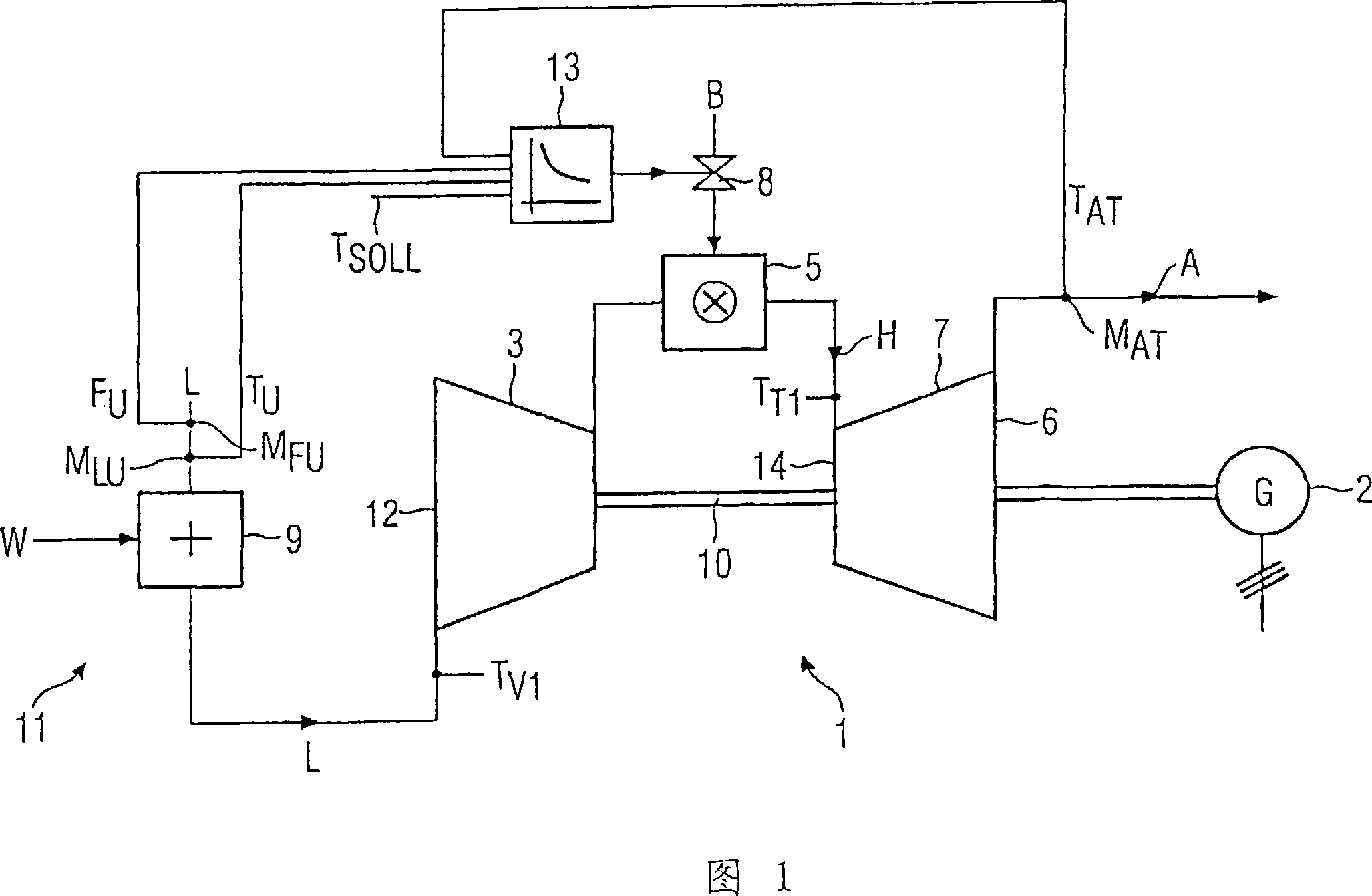

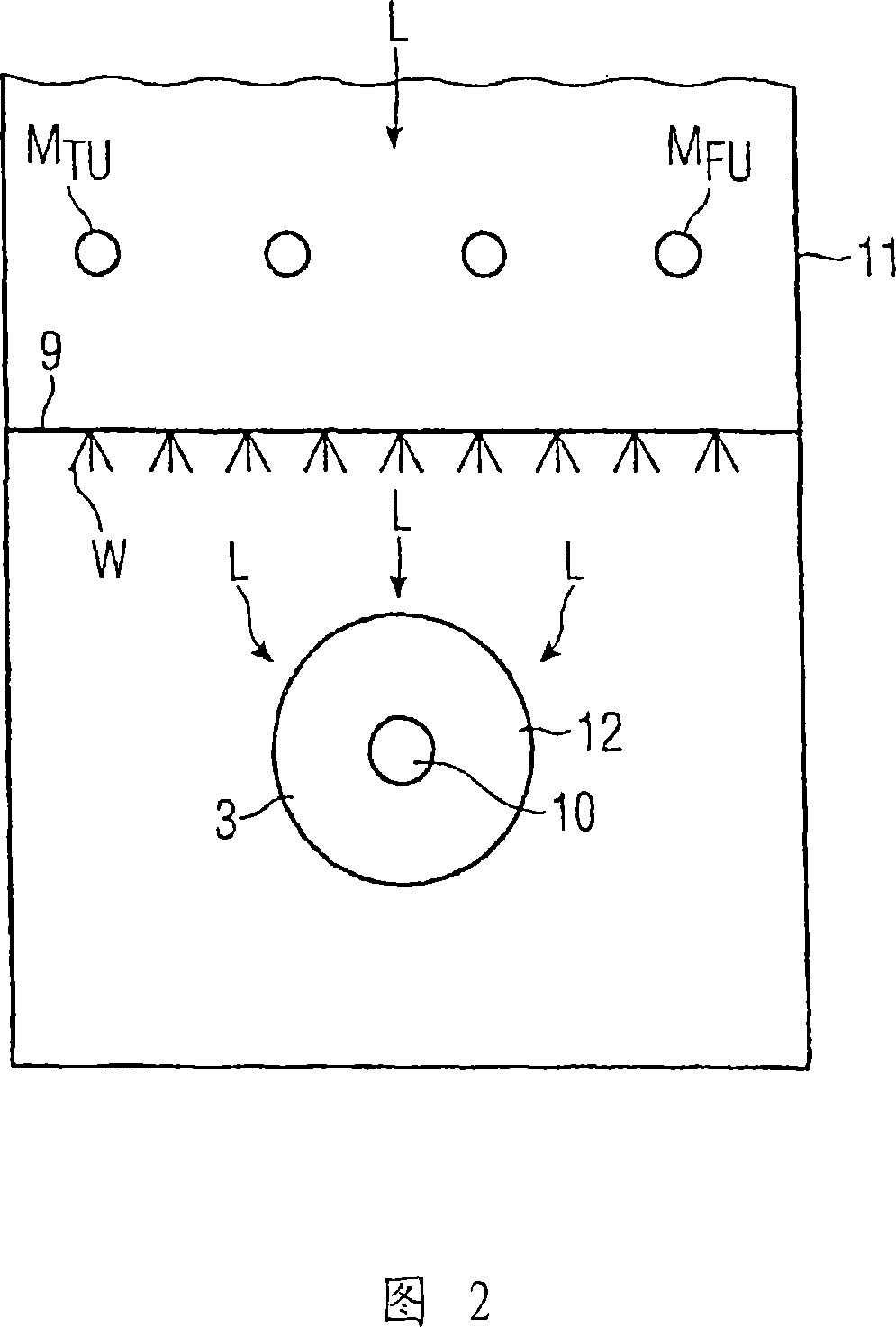

[0025] FIG. 1 schematically shows a gas turbine plant for converting fossil energy into electrical energy by means of a gas turbine 1 and a generator 2 connected thereto. The stationary gas turbine 1 essentially has a compressor 3 , a combustion chamber 5 and a turbine section 7 . Compressor 3 is connected to turbine section 7 and generator 2 via a common rotor shaft 10 .

[0026] During operation of the gas turbine 1 , air is sucked in and compressed by the compressor 3 through a suction chamber 11 . In a burner, the compressed air is mixed with a combustion medium B which can be delivered via a shut-off device 8 and is fed to the combustion chamber 5 . This mixture is combusted during operation of the gas turbine to form a hot flue gas H which then flows into the turbine section 7 . The hot flue gas expands in the turbine section 7 to perform work and simultaneously drives the rotor shaft 10 . The hot flue gas H then leaves the gas turbine 1 as exhaust gas and enters an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com