Rotary type compressor and refrigeration circulating device having the same

A technology of rotary compressor and compression mechanism, applied in rotary piston machinery, rotary piston/oscillating piston pump components, and elastic fluid rotary piston/oscillating piston pump combinations, etc. Considering the problem of the rotating body assembly, the vibration cannot be sufficiently reduced, and the effect of excellent vibration resistance is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, a rotary compressor and a refrigeration cycle apparatus having the rotary compressor according to an embodiment of the present invention will be described with reference to the drawings.

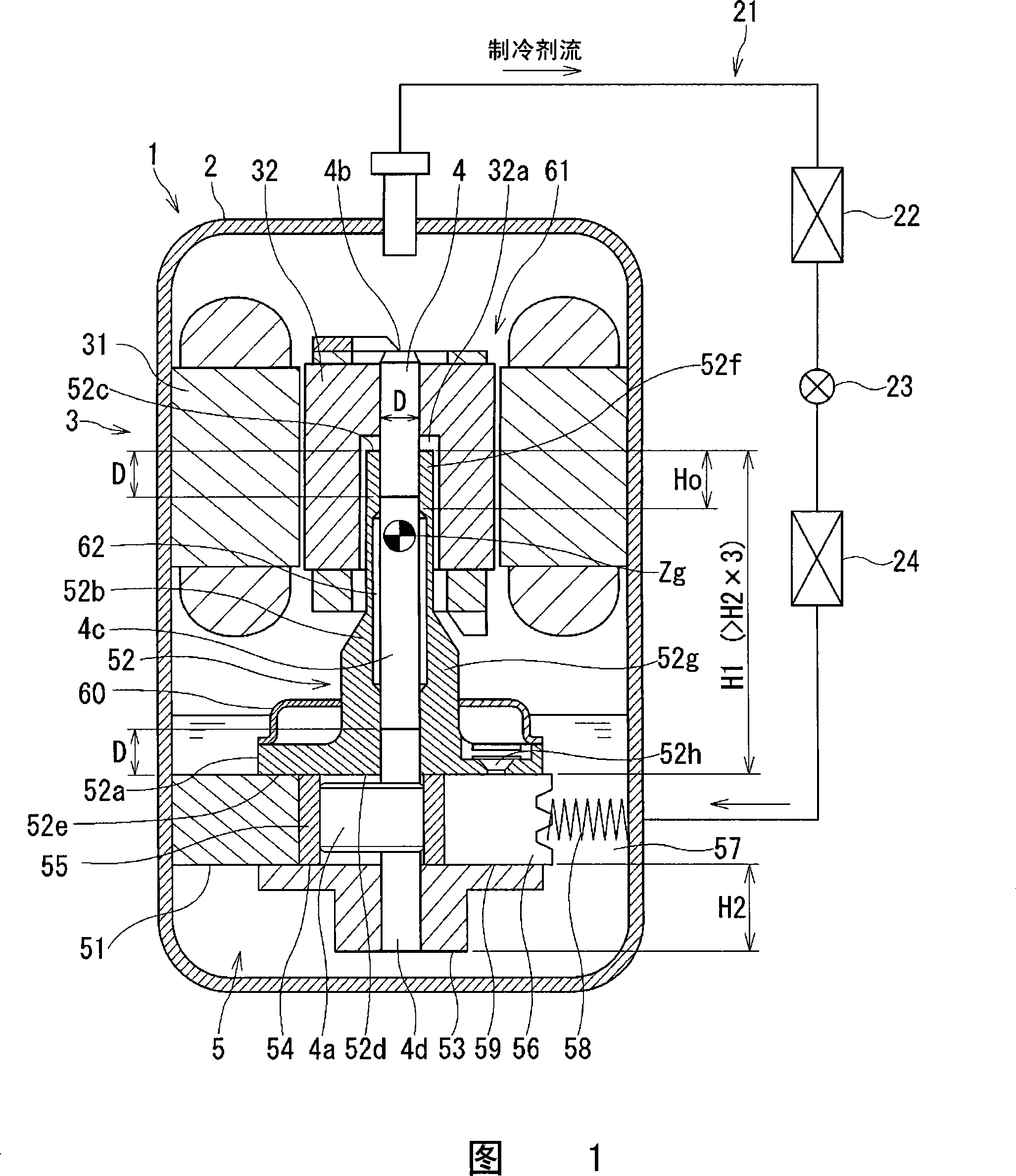

[0045] FIG. 1 is a schematic diagram of a rotary compressor and a refrigeration cycle device having the rotary compressor according to an embodiment of the present invention.

[0046] As shown in FIG. 1 , in the refrigeration cycle device 21 of the present invention, the rotary compressor 1 , condenser 22 , expansion device 23 and evaporator 24 of this embodiment are connected in a ring shape with pipes.

[0047] The rotary compressor 1 has an airtight container 2 , and includes a motor unit 3 accommodated in the airtight container 2 , and a compression mechanism unit 5 connected to the motor unit 3 via a rotating shaft 4 .

[0048] The motor part 3 includes: a stator 31 pressed into the airtight container 2, and a rotor 32 rotatably arranged on the inner periphery of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap