Ripple compensator against vibration

A corrugated compensator and anti-vibration technology, which is applied in the field of corrugated compensators, can solve the problems of reduced service life of corrugated compensators, corrugated induced vibration, and affecting service life, etc., and achieves the advantages of preventing flow resistance, prolonging service life, and strong pressure bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the drawings and specific embodiments:

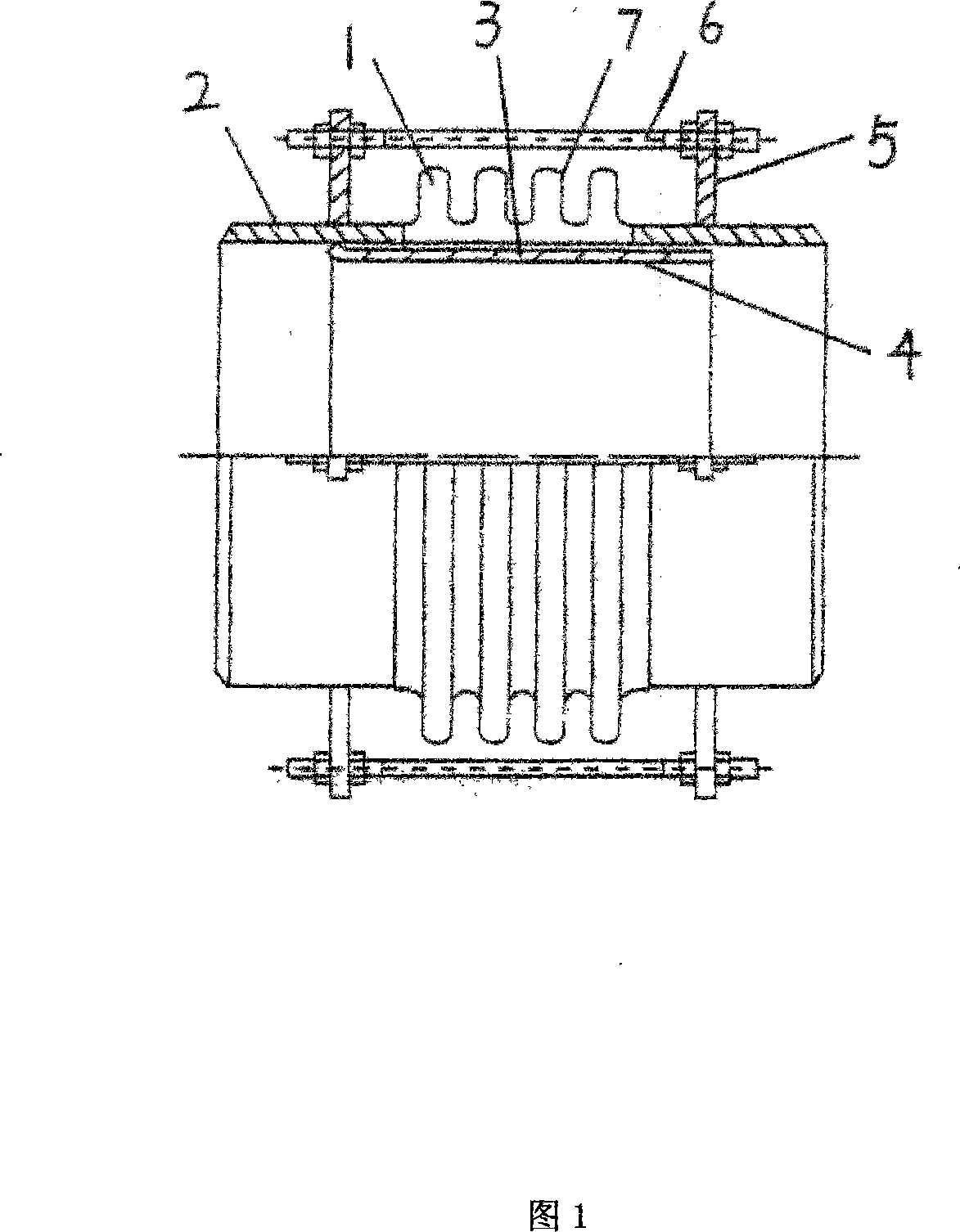

[0010] As shown in Figure 1, the bellows 1 and the end pipe 2 are connected to form an integral structure. The bellows 1 is provided with an inner sleeve 3, and the inner surface of the inner sleeve is evenly sprayed with an anticorrosive layer 4, and the outer ends of the end pipes There are flanges 5 on the surface, and the flanges are integrated with the end pipe. Several reinforcing ribs 6 are installed on the flanges. The reinforcing ribs can be ordinary bolts. The outer surface of the corrugated pipe 1 is evenly sprayed with an anti-corrosion layer 7. In addition, the filling between the corrugated pipe and the inner sleeve can also be provided with a layer of heat-resistant and heat-resistant material. The structure of the bellows 1 can be U-shaped, single-layer, double-layer, and multi-layer; the type of corrugated compensator can be single axial type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com