Method for measuring tensile strength of connecting piece base

A technology of connectors and bases, which is applied in the field of measurement of tensile force bearing values, can solve the problems of waste of labor and material costs, bulky and inconvenient use, and large difference in accuracy, so as to save manpower and material resources, and is easy to operate. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

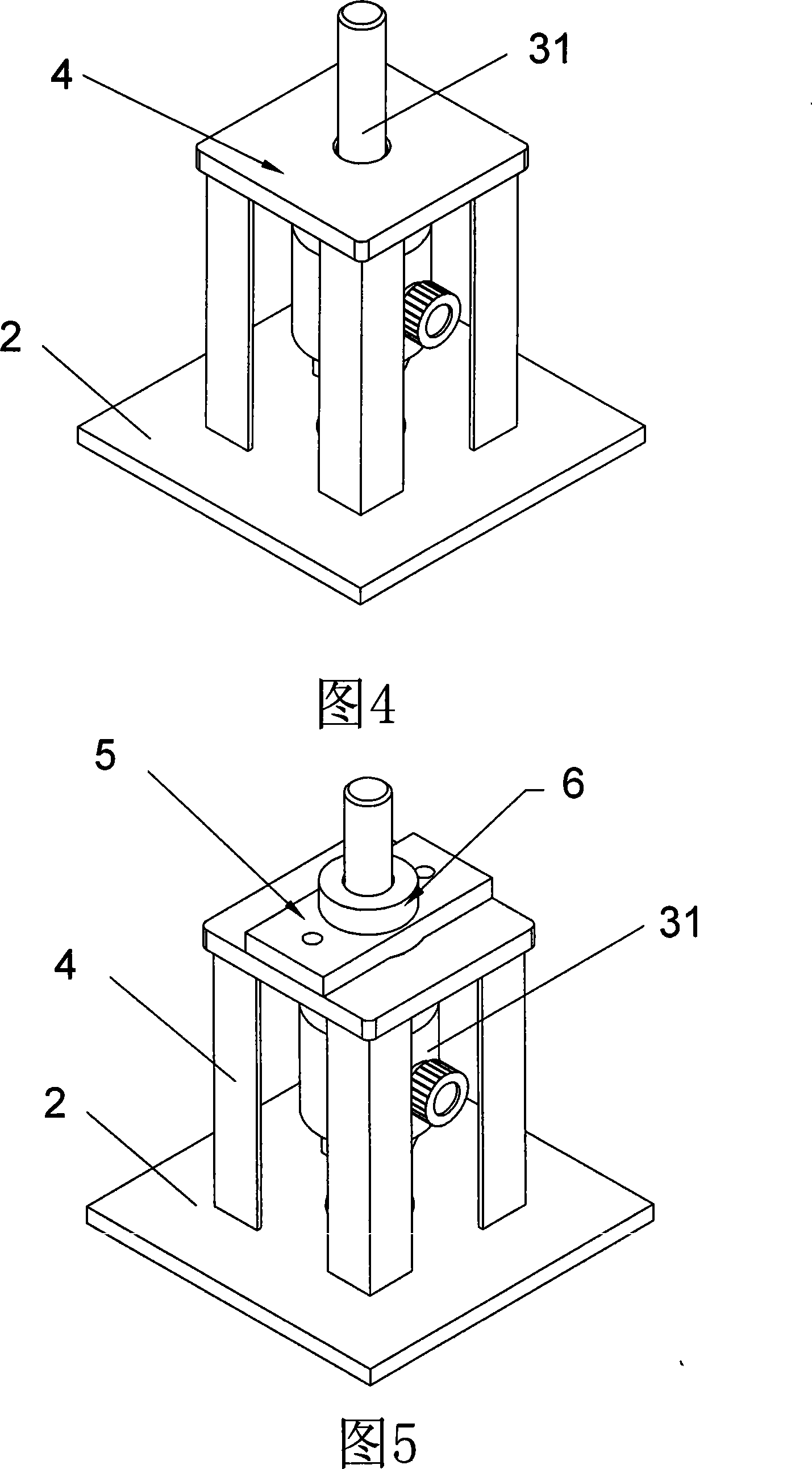

[0027] The method for measuring the tensile strength of the connector base of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

[0028] What is used in the measuring method of the present invention is a portable tension meter, and its controllable tension range: 0-99999N. The tensile instrument is a resistive tensile instrument with small size and accurate force measurement; the data display device is equipped with a digital display window, and the data display is intuitive and clear; the tensile device 31 of the tensile instrument 3 and the data display device 33 are only connected by a data line 32 . Other tools and fixtures required for the tensile test of the connector base are also relatively simple, which simplifies the entire test process and can be completed by a single person. The traditional mechanical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com