Control method for fabrication technology of analysis estimation-correcting integrated circuit by time series

A technology of time series analysis and manufacturing process, which is applied in the direction of general control system, circuit, adaptive control, etc., and can solve the problem that the prediction algorithm cannot be applied correctly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

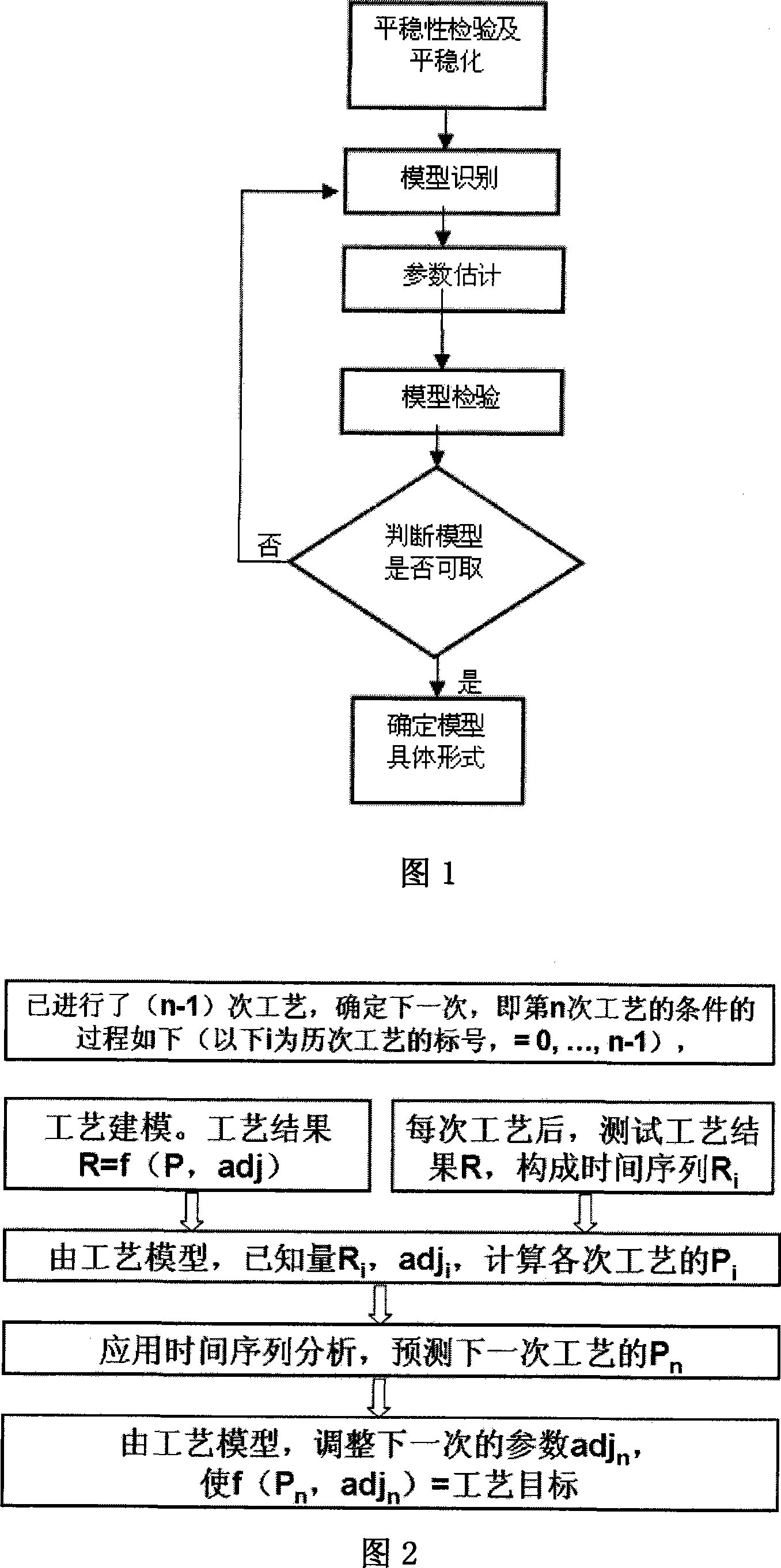

[0020] The invention provides a method for controlling the manufacturing process of an integrated circuit using time series analysis prediction-correction. Fig. 2 is a flow chart of the control method of "process modeling-time series analysis and prediction-process condition correction". The following is an example of the epitaxial process in integrated circuit manufacturing, combined with the flow chart of the control method of "process modeling - time series analysis and prediction - process condition correction" shown in Figure 2 to illustrate how time series prediction is applied to integrated circuit manufacturing , for advanced process control.

[0021] For the epitaxy process, the thickness of the epitaxy is proportional to the growth time, so the following process model can be established:

[0022] Thickness = growth time × growth rate of epitaxial layer

[0023] Controllable process parameters in the epitaxial process include gas flow rate, aeration time, gas doping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com