Flexible stereo magnetic iron improved structure for decoration and manufacturing method thereof

A technology that improves the structure and manufacturing method, and is used in the manufacture of inductors/transformers/magnets, magnetic objects, magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

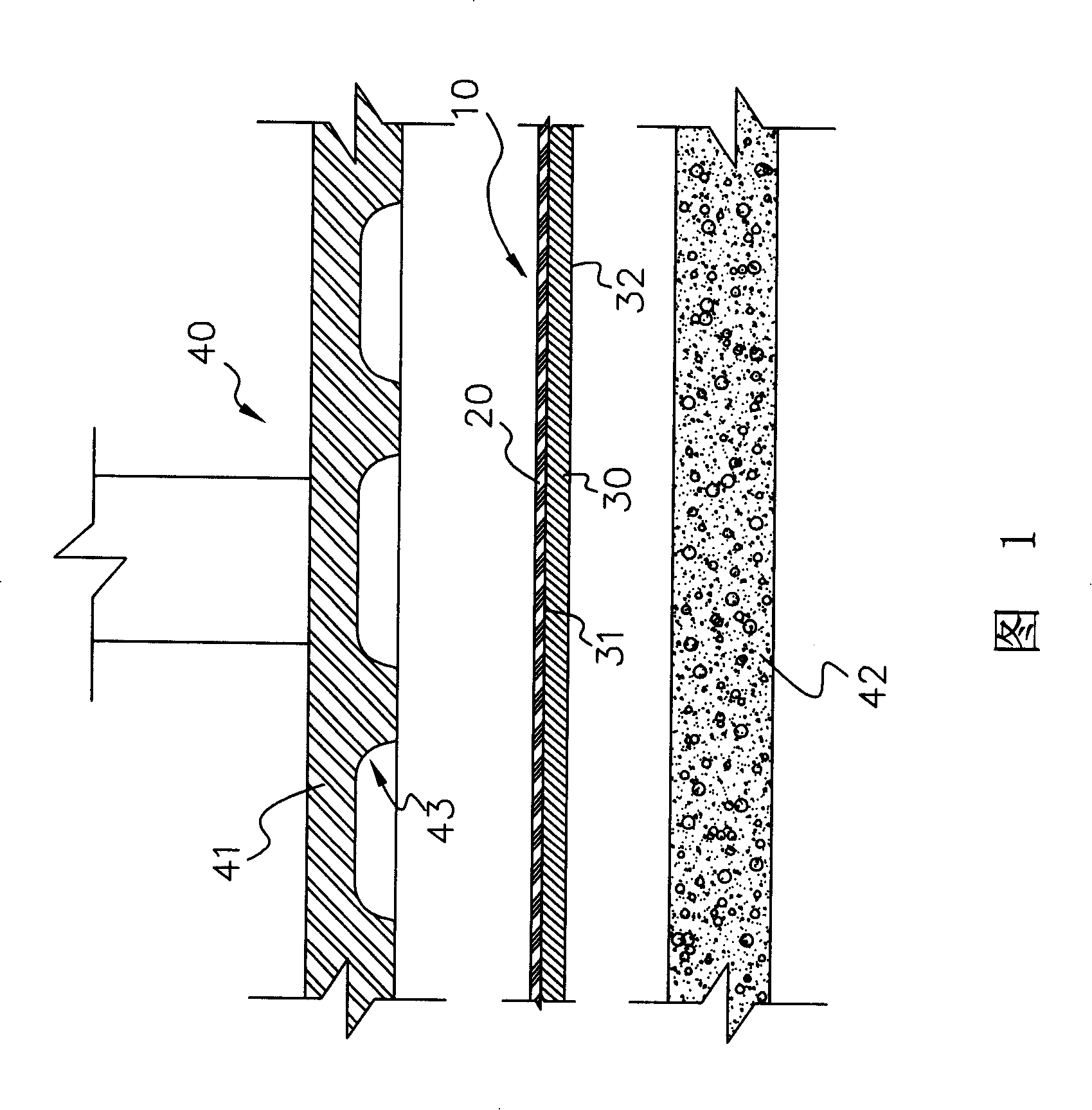

[0032] Please refer to FIG. 1 , the improved structure of the soft three-dimensional magnet for decoration of the present invention has a body unit, generally indicated by reference number 10 ; the body unit 10 includes a surface layer 20 and a base layer 30 . Patterns or characters are printed on the surface layer 20, and the base layer 30 is pasted or bonded together to form an integral sheet unit 10; in a feasible embodiment, the base layer 30 is a magnetic material. The base layer 30 includes a first side 31 and a second side 32 ;

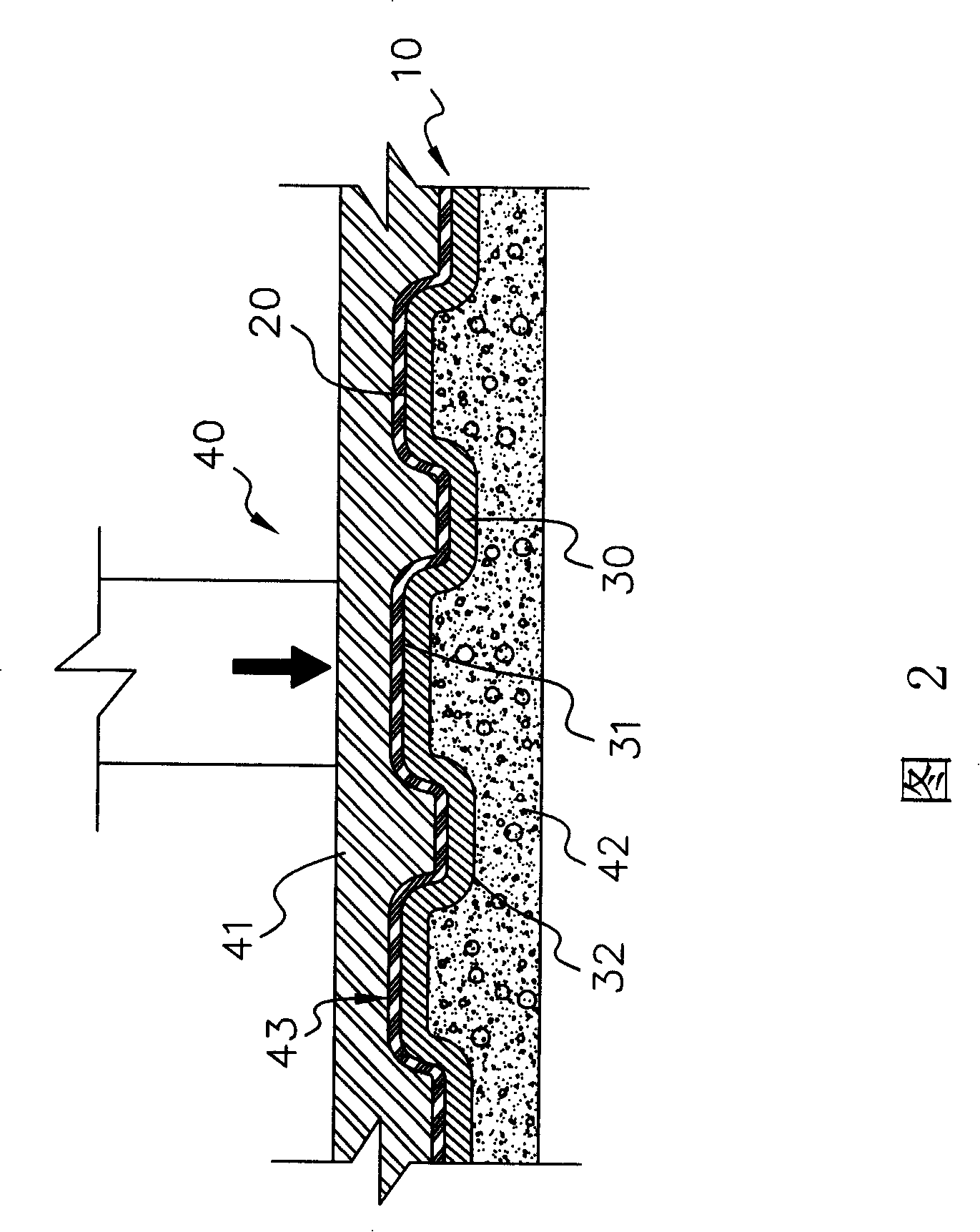

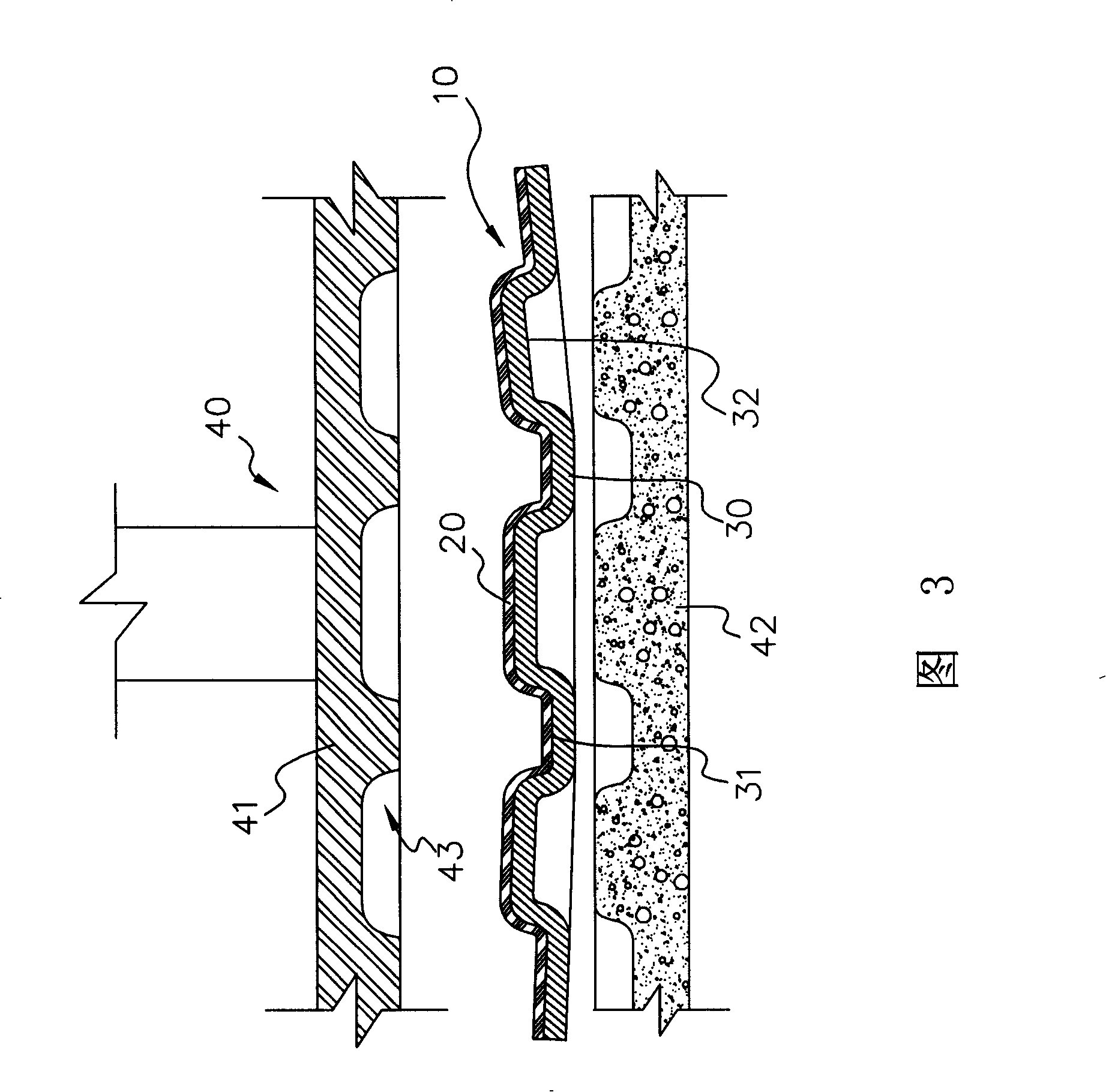

[0033] Please refer to Fig. 2 and Fig. 3, above-mentioned sheet unit 10 can pass through the high-frequency or ultrasonic molding operation of a mold group 40, and form a soft three-dimensional magnet for decoration that produces accurate concave-convex three-dimensional graphics along the pattern or text. In the adopted embodiment of the present invention, the mold set 40 includes an upper mold 41 and a lower mold 42 formed by a soft material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com