Drive device

A driving device and casing technology, applied in magnetic drive clutches, non-mechanical drive clutches, transportation and packaging, etc., can solve problems such as sensor short-circuit faults and short-circuit faults, and achieve the effect of preventing short-circuit faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

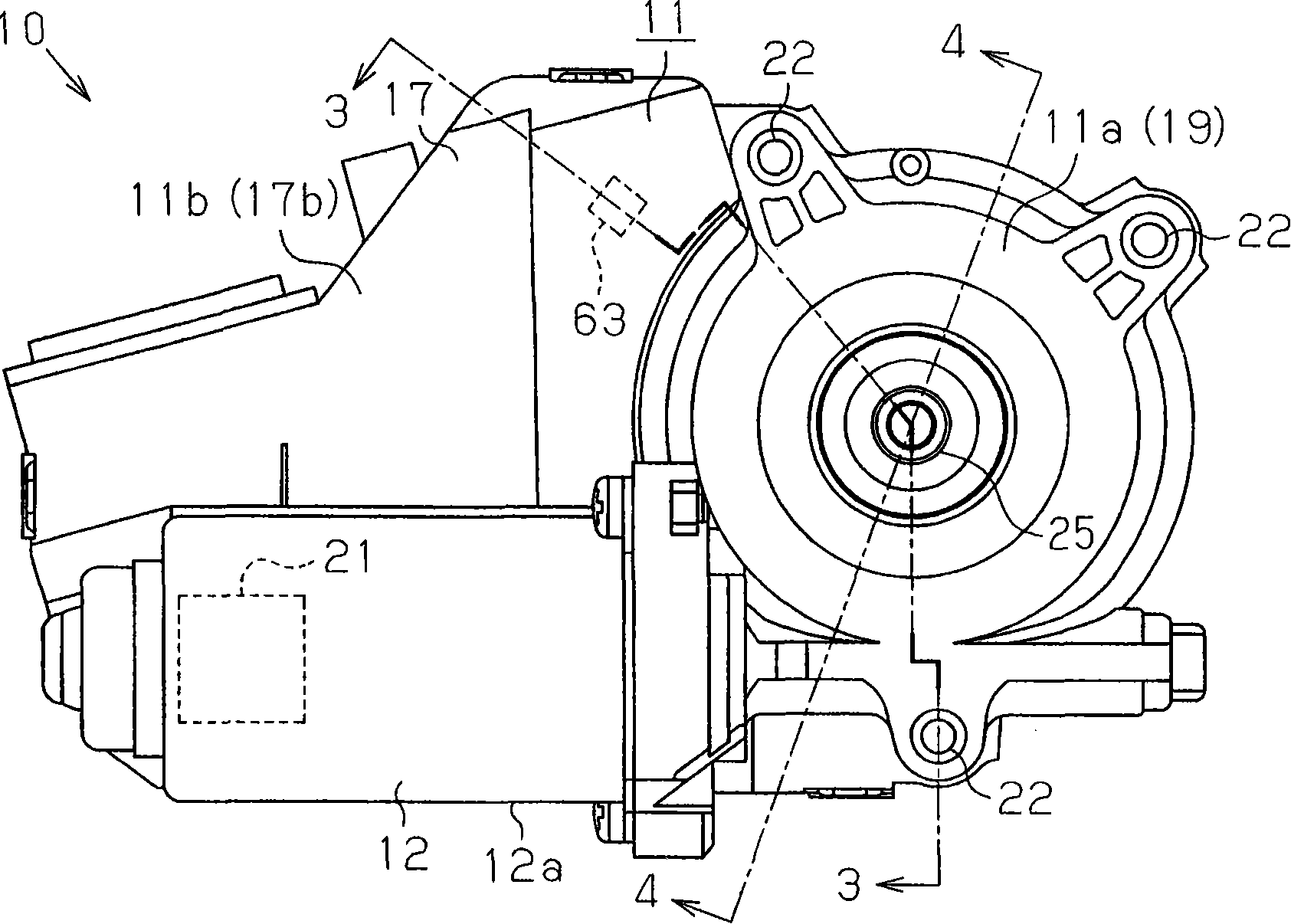

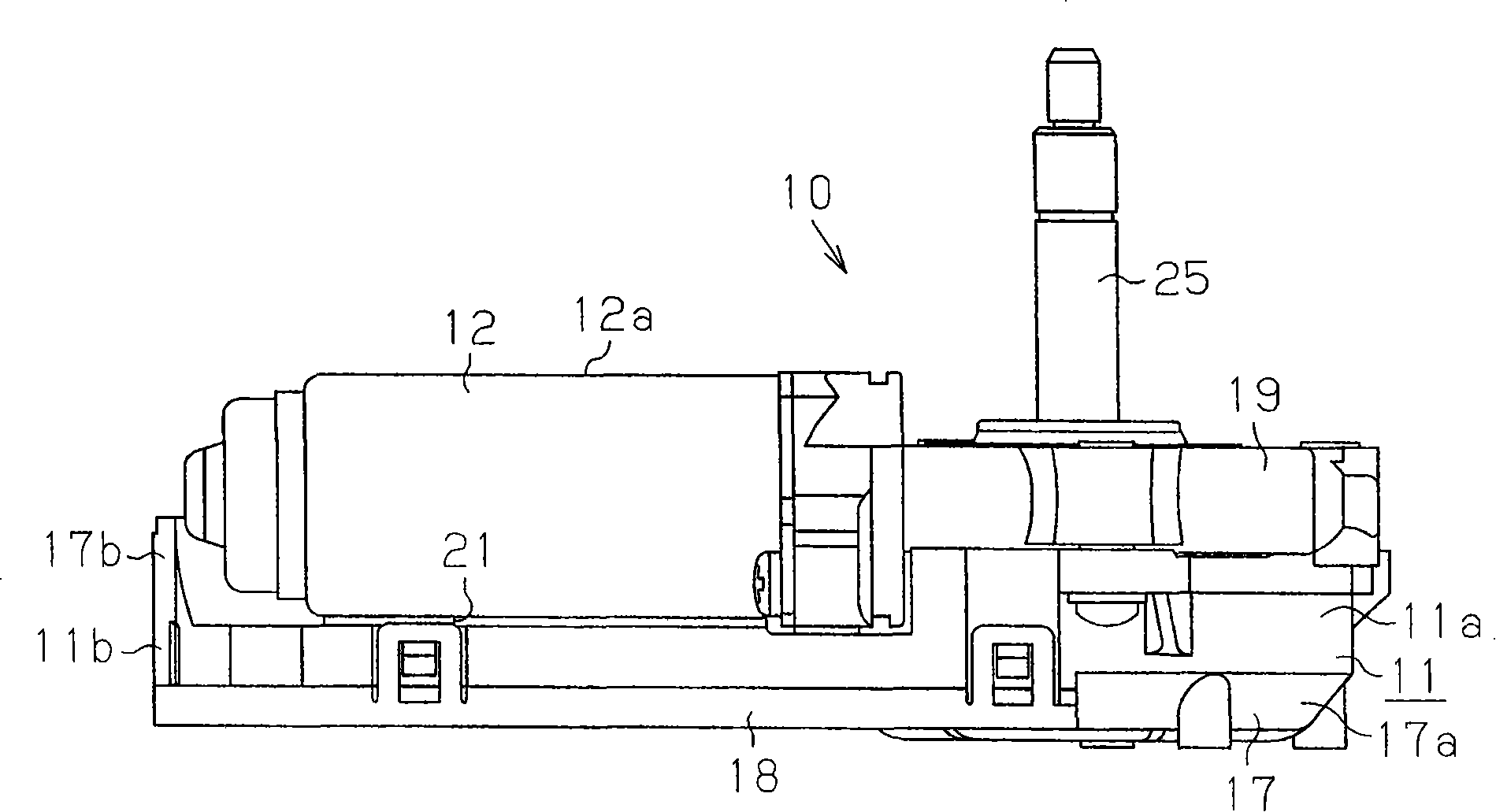

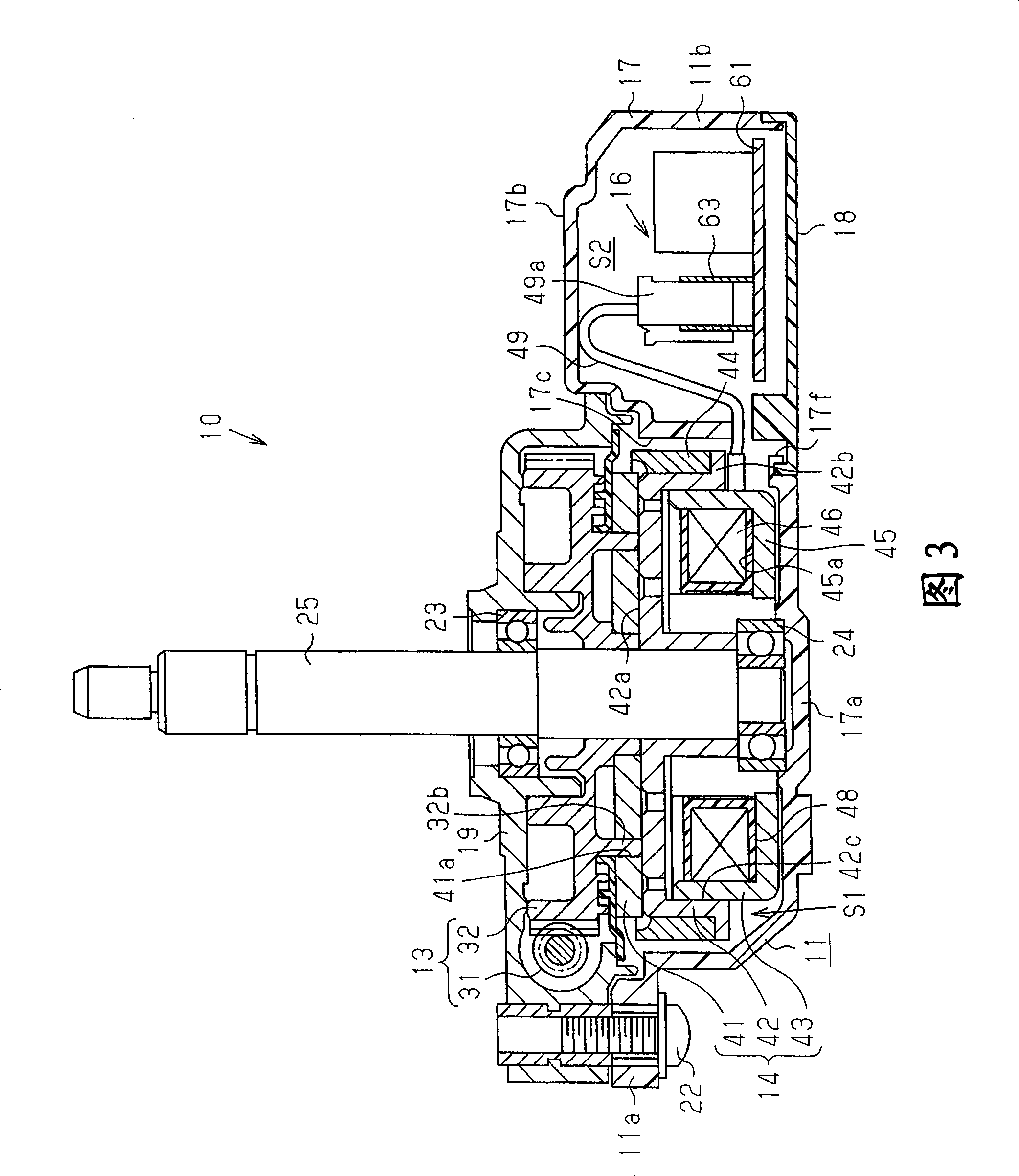

[0020] Hereinafter, an embodiment embodying the present invention will be described based on the drawings.

[0021] like figure 1 4, the driving device 10 includes: a casing 11, a motor 12, a reduction mechanism 13, a friction electromagnetic clutch mechanism 14, a sensor 15, and an electronic control unit (hereinafter referred to as "ECU") 16 as a control device. . The reduction mechanism 13 and the electromagnetic clutch mechanism 14 constitute a drive transmission mechanism section. The casing 11 includes a housing 17 , an ECU cover 18 , and a motor casing 19 .

[0022] The above-mentioned case 17 is made of a resin material, and has an integral first case part 17a and a second case part 17b. The first case portion 17a and the second case portion 17b are opened in opposite directions, that is, openings are formed facing upward and downward in FIG. 3 , so that the case 17 has an approximately S-shaped cross section. A partition wall 17c extending in the axial direction o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap